Novel material re-cleaning pulping device for gold ore tailing pond

A technology for gold mine tailings and materials, which is used in the field of precious metal mineral re-sorting equipment, can solve the problems of not finding a pulper, blocking screening holes or gaps, and inability to separate mud, slag, and debris, and achieve continuous machine production. , Improve the effect of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

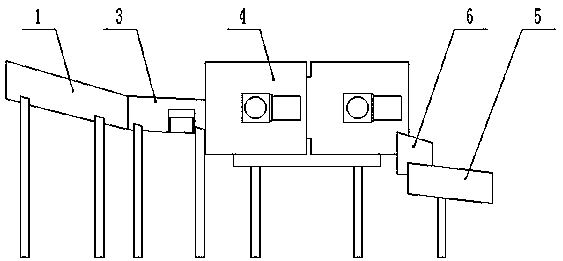

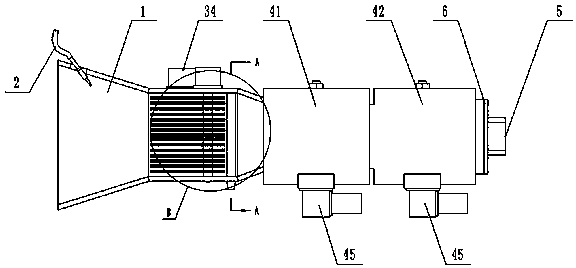

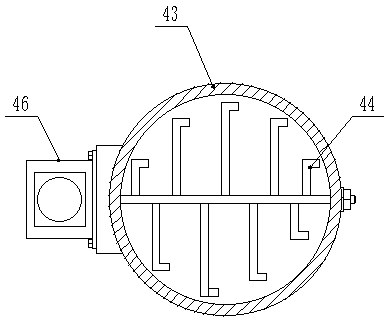

[0036] Such as Figure 1 to Figure 8 As shown, a novel gold ore tailings pond material reselection pulping device of the present invention comprises: a feed tank 1, a water pipe 2, a screen body 3, a cutting and stirring tank 4 and a slurry outlet 5; the feed tank 1 It is a feeding tank with an open top, and a water pipe 2 is fixed on the tank wall of the feeding tank 1, and the outlet of the water pipe 2 is aligned with the tank body of the feeding tank 1, and the outlet of the feeding tank 1 is connected to the screen The feed port of the sieve body 3 is docked, the sieve body 3 is used for screening qualified slurry mud, the discharge port of the sieve body 3 is docked with the feed port of the cutting and stirring tank 4, and the cutting and stirring tank 4 is used for crushing Mud and stirring mud, the slurry outlet 5 is docked with the cutting and stirring groove 4.

[0037] One end of the water pipe 2 is provided with a high-pressure water gun, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com