Large fan welding positioning tooling and large fan welding positioning method

A technology for welding positioning tooling and fans, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting the overall appearance of the fan shell, the overall failure of the fan, and the different sizes of the flanges. To avoid the collision and deformation of the casing, save manpower and time resources, and meet the effects of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

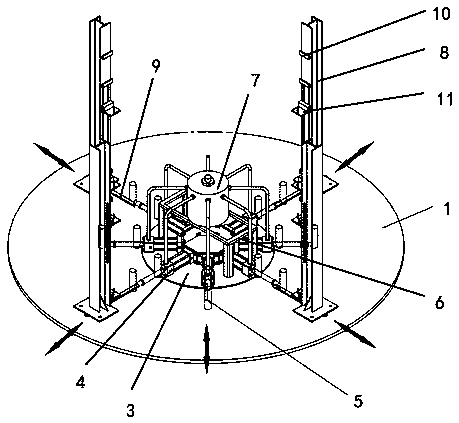

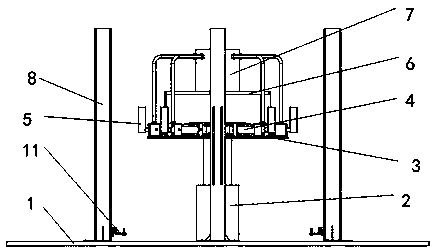

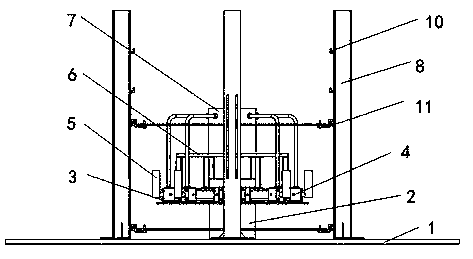

[0032] The invention discloses a large-scale fan welding positioning tool and a welding positioning method used in the welding and assembly process of a large-scale fan, specifically as follows.

[0033] Such as Figure 1~Figure 3 As shown, a welding positioning tool for a large-scale fan includes a tooling platform 1, and also includes a shell positioning component for realizing the round positioning of the fan casing and a flange positioning component for placing and positioning the flange. Both the housing positioning assembly and the flange positioning assembly are arranged on the tooling platform 1, the housing positioning assembly is arranged at the center of the tooling platform 1, and the flange positioning assembly is movably arranged on the tooling platform 1. The housing locates the outer peripheral side of the assembly.

[0034] The housing positioning assembly includes a vertical driving cylinder 2 arranged at the center of the tooling platform 1, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com