Transmission shaft on wind power generation equipment

A technology for wind power generation equipment and drive shafts, applied in the field of drive shafts, can solve problems such as easy wear of drive shafts, achieve the effects of guaranteed operation, scientific and reasonable overall structure, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

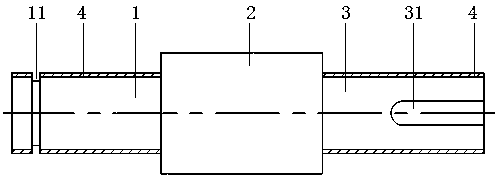

[0021] refer to figure 1 , the present invention is realized in this way: a transmission shaft on wind power generation equipment, which includes a first shaft body 1, a stepped portion 2 and a second shaft body 3 that are adjacently connected in sequence, and the outer diameter of the stepped portion 2 The size is larger than the outer diameters of the first shaft body 1 and the second shaft body 3, and the outer diameters of the first shaft body 1 and the second shaft body 3 are consistent.

[0022] refer to figure 1 As shown, in the present invention, the outer circular surfaces of the first shaft body 1 and the second shaft body 3 are provided with a functional layer 4, and the functional layer 4 is a nitriding layer or a carbonitriding layer; nitriding is combined in a medium A chemical heat treatment process that allows nitrogen atoms to penetrate into the surface of the workpiece at a certain temperature. It is used to change the chemical composition and structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com