Kitchen total heat recovery fresh air ventilator

A technology of total heat recovery and fresh air blower, which is applied in the field of fresh air and kitchen oil fume purification, kitchen full heat recovery fresh air blower, oil fume full heat recovery oxygen supply, and fresh air blower. It can solve oil smoke pollution, environmental hypoxia, energy waste, etc. problem, to achieve the effect of protecting pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

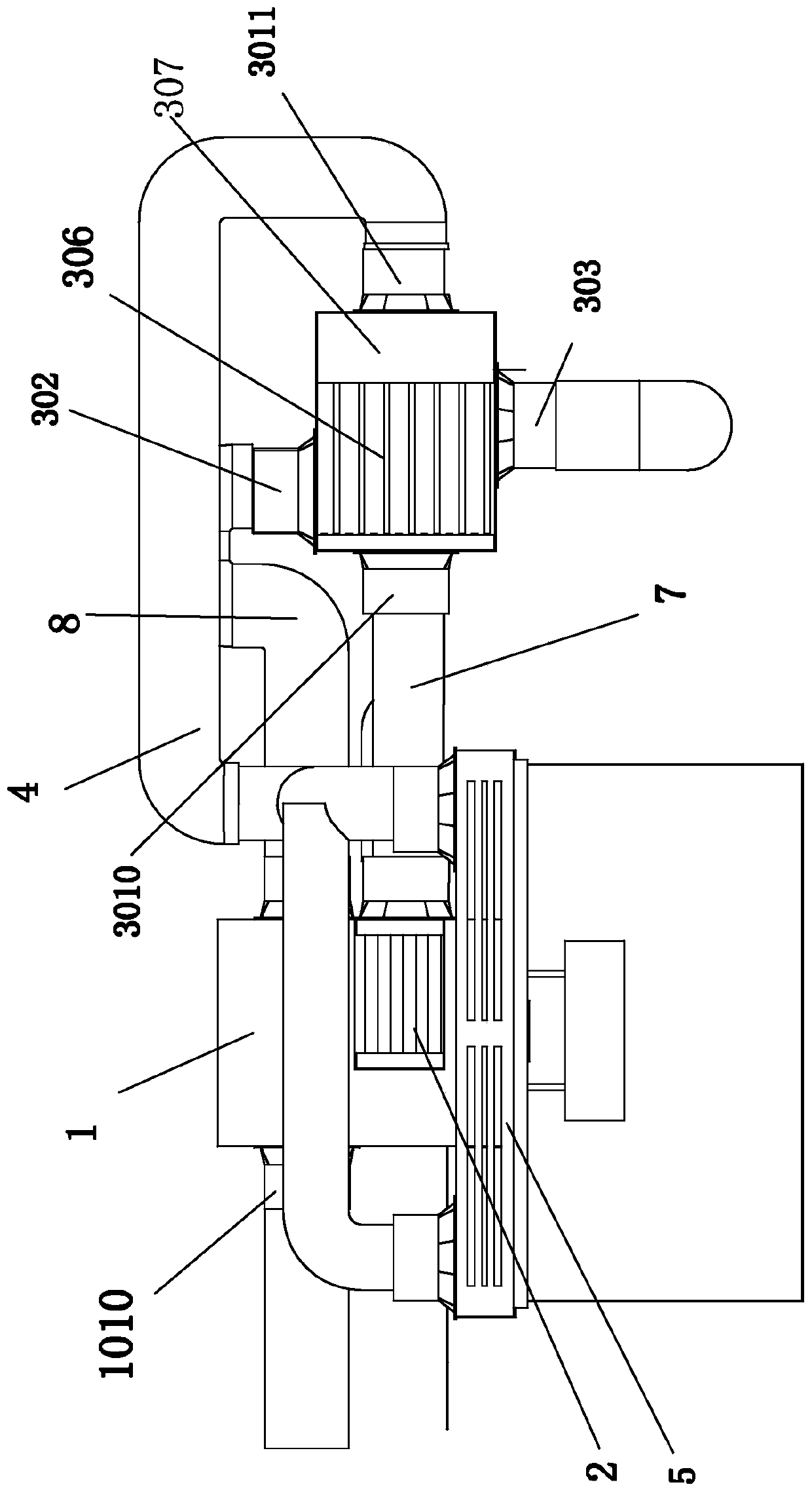

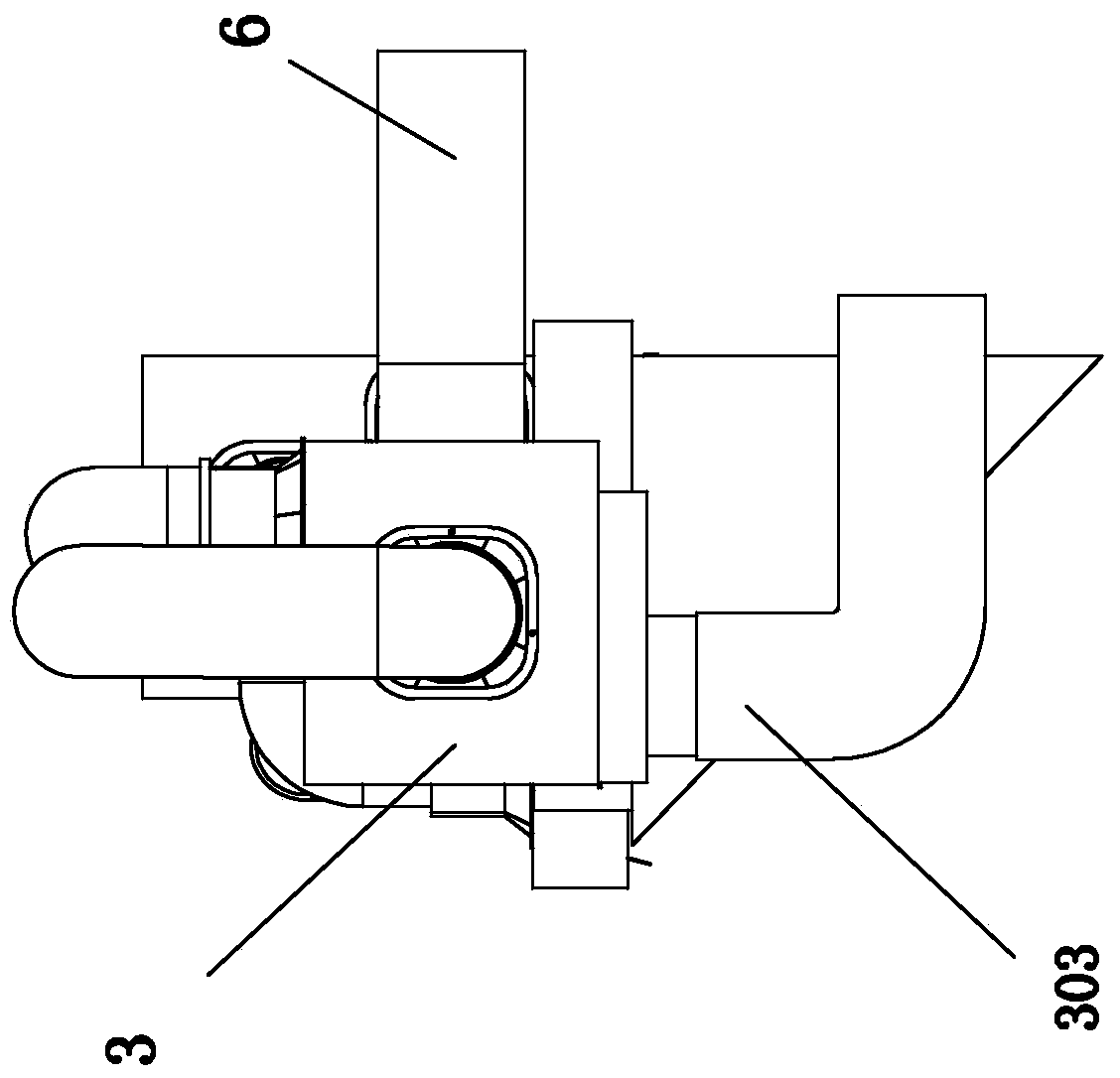

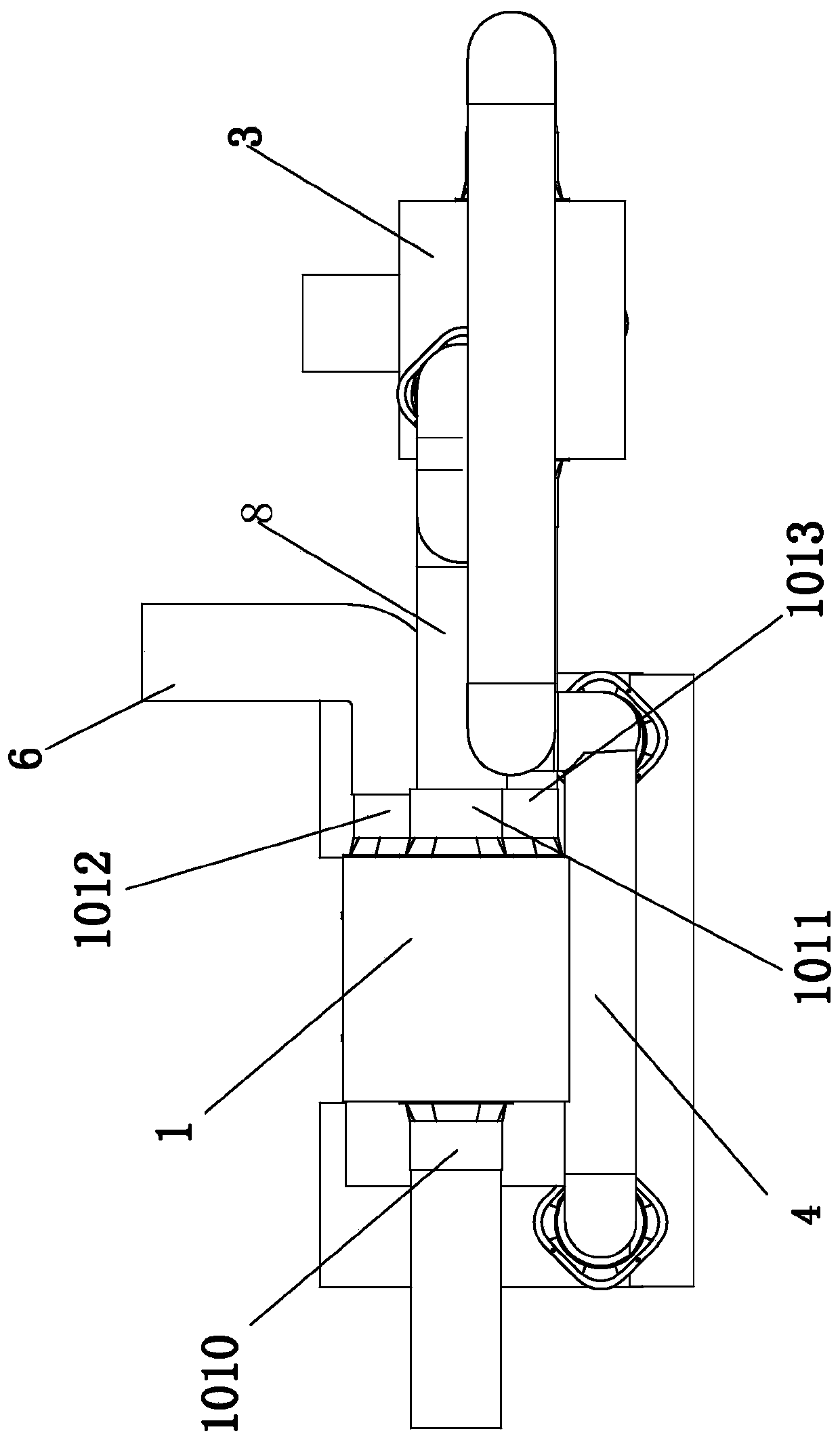

[0042] Such as Figure 1 to Figure 6-5 As shown, a kitchen full heat recovery fresh air fan, such as Figure 1 to Figure 2-4 As shown, a range hood 1 is included, and the range hood 1 includes a casing 101 on its upper part, a smoke shield 102 on its lower part, and a dirty air outlet 1010. Below the smoke shield 102 is a combustion furnace (not shown in the figure). Shown), the housing 101 of the range hood 1 is provided with a sewage air direct discharge channel 103 and a high-temperature heat exchanger channel 104, and the single channel is changed to a double channel, and its function is increased by 2 times; the bottom of the sewage air direct discharge channel 103 is provided with Sewage air inlet 105, and a sewage fan 106 is arranged above the sewage air inlet 105;

[0043] The range hood 1 also includes a dirty air right air outlet 1011, a fresh air rear air inlet 1012, and a fresh air front air outlet 101; the kitchen full heat recovery fresh air fan also includes a ...

Embodiment 2

[0060] Such as Figure 7-1 to Figure 7-2As shown, a three-way pipe (not shown in the figure) is arranged in the fresh air inlet pipe 6, and the inlet end of the three-way pipe is directly connected to the outside of the kitchen, and the first outlet of the three-way pipe is connected with the rear air inlet 1012 of the fresh air; The outlet is connected to the fresh air straight-through air inlet 3012 on the upper part of the fresh air outlet cavity 307 of the low-temperature heat exchanger 3 through a damper (not shown in the figure), and the fresh air is directly led to the fresh air fan 308, and sent to the fresh air branch from the fresh air low air outlet 3011. The piping 4 distributes the fresh air to the fresh air left inlet 504 and the fresh air right inlet 505, and the fresh air distribution box 5 distributes the fresh air left outlet 501 facing downward, the fresh air right outlet 502, and the fresh air left outlet window 508 facing forward , Fresh air right air outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap