Rock size defect repair method and standard test piece preparation method

A standard test piece and defect repair technology, applied in the field of rock testing, can solve problems such as difficulty in making rock test pieces, and achieve the effects of great application value, improved utilization, and expanded scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A kind of repairing method of rock size defect

[0042] The mold used is composed of 5 completely transparent square plexiglass plates, which are formed into a square box by sealing the glass plates with organic insulating silicone grease. Concrete preparation steps are:

[0043] (1) Thoroughly clean the rock to be tested and arrange it in the mold, such as figure 1 shown;

[0044] (2) Take the mixture of CY-39 epoxy resin and YS-T31 resin curing agent with a mass ratio of 100:34 and cast it in the mold;

[0045] (3) Put it in a constant temperature blast drying oven at 18°C for 48 hours. When the specimen has a mechanical strength greater than 50MPa, the mold can be removed;

[0046] (4) Use a stone grinder to grind the test surface flat, which can be used as a test piece for abrasiveness, such as figure 2 shown.

[0047] The mechanical parameters of the specimens were detected by conventional methods, and the results are shown in Table 1.

[004...

Embodiment 2

[0051] Embodiment 2: A kind of preparation method of abrasiveness test specimen

[0052] The standard sample in this abrasiveness test is a cube with a side length of 40 mm. The mold used is composed of 5 completely transparent square plexiglass plates, which are formed into a square box by sealing the glass plates with organic insulating silicone grease.

[0053] In order to detect the law of abrasiveness of various rock-forming minerals and their combined working conditions, the following method was used to prepare the specimens for the abrasiveness test:

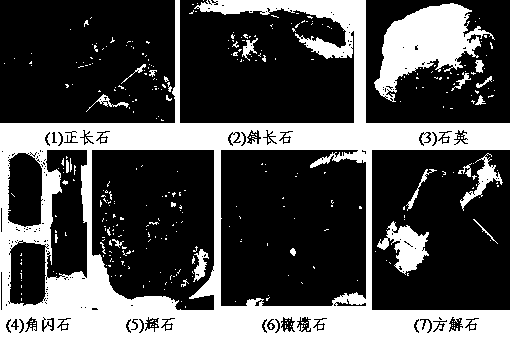

[0054] (1) Select various types of rocks with the same degree of weathering, the seven most common rock-forming minerals in nature such as image 3 shown;

[0055](2) Use a PCL straight-through crusher to grind the rocks into 15mm diameter particles, clean them and arrange them in the mold; take CY-39 epoxy resin and YS-T31 resin curing agent with a volume ratio of 100:34 The mixture is cast in a mould;

[0056] When ...

Embodiment 3

[0060] Embodiment 3: A kind of preparation method of uniaxial tensile test specimen

[0061] The specimen used in the uniaxial tensile test is dumbbell-shaped, and the two ends of the mold used are T-shaped boxes, which are connected as a whole by strapping plates. Each T-shaped box is composed of 10 completely transparent plexiglass plates. The upper part is opened and sealed with organic insulating silicone grease to form a whole, such as Image 6 shown.

[0062] Concrete preparation steps are:

[0063] (1) Thoroughly clean the rock to be tested, and place it on the board of the mold with T-shaped boxes at both ends. All interfaces are sealed with organic insulating silicone grease, and each end of the defective rock specimen has a length of 1.5 cm into the T. shaped box, such as Image 6 As shown, the purpose is to increase the contact surface between the resin and the defective rock specimen. After the resin is cured, it can provide sufficient bonding force, which can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com