Hydrogen fuel cell CCM membrane electrode combination or CCM membrane electrode assembly automatic assembling system

A membrane-electrode combination and membrane-electrode assembly technology, which is applied in fuel cells, electrical components, circuits, etc., can solve problems such as low efficiency, air bubbles in CCM membrane-electrode assemblies, and low lamination positioning and alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

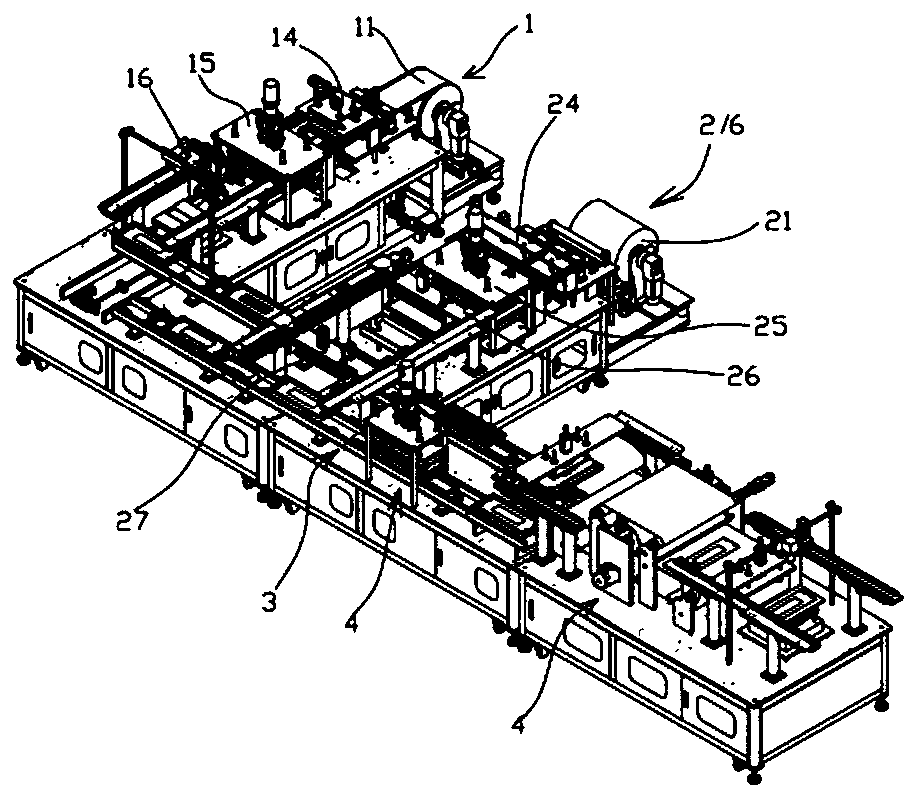

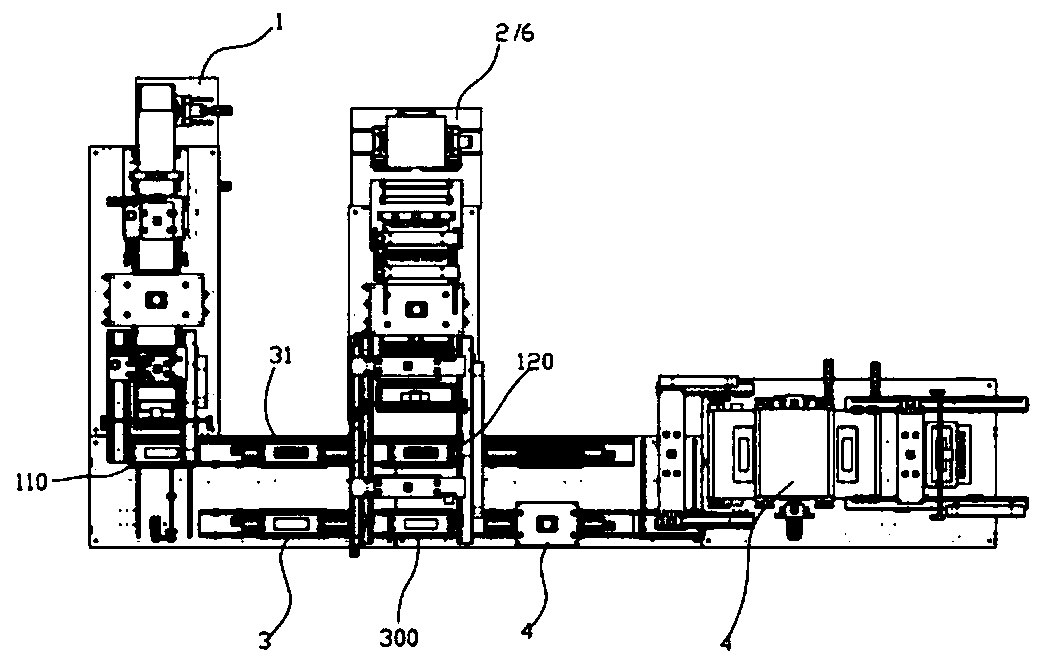

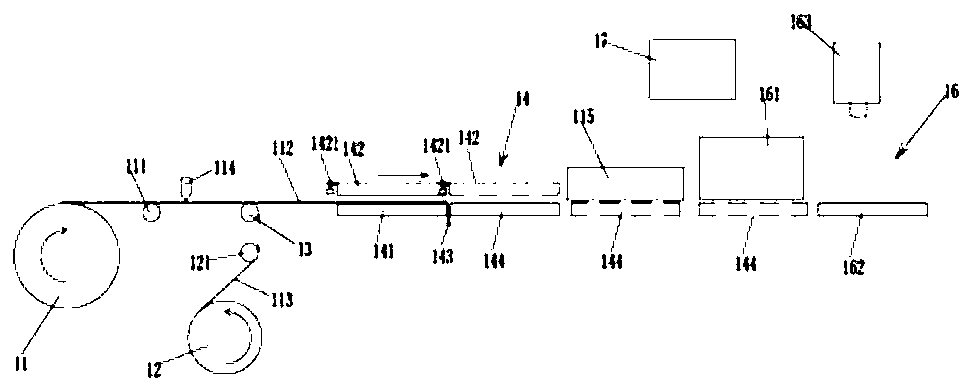

[0081] See figure 1 with figure 2 , figure 1 with figure 2 What is disclosed is an automatic assembly system for a hydrogen fuel cell CCM membrane electrode assembly, which includes a CCM membrane electrode sheeting and feeding system 1, a PET film sheeting and feeding system 2, a positioning circulation clamp system 3, and a hot pressing system 4; The CCM membrane electrode sheet-making supply system 1 and the PET film sheet-making supply system 2 are arranged on one side of the positioning circulating clamp system 3;

[0082] The PET film sheet feeding system 2 sets the die-cut first PET film sheet with the adhesive side up on the vacuum suction plate 31 of the first station of the positioning circulation clamp system 3, and the vacuum suction plate 31 Adsorption positioning;

[0083] The positioning circulation fixture system 3 moves the vacuum suction plate 31 with the first PET film to the station 110 of the CCM film electrode preparation and feeding system 1; the CCM film e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com