A vertical cross-flow filtration integrated device based on hollow fiber membrane

A cross-flow filtration, integrated device technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve good scouring effect, increase balance flux, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

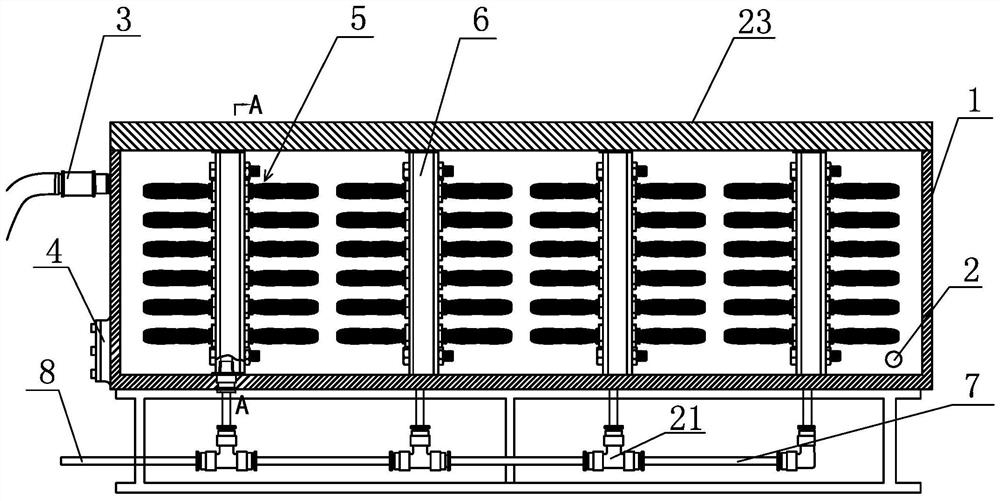

[0034] A hollow fiber membrane filter element assembly vertical cross-flow filtration integrated device, such as figure 1 and figure 2 As shown, there is a pressure vessel 1 with a cubic structure, a raw material liquid inlet 2 is arranged at the lower right end of the front of the pressure vessel 1, a concentrated liquid outlet 3 is arranged at the upper end of the left side surface of the pressure vessel 1, and a waste liquid discharge port is arranged at the lower end of the left side surface 4. At least one filter element integration assembly 5 is arranged in the pressure vessel 1, and the flow direction of the material and liquid in the pressure vessel 1 is vertically around the filter membrane surface of the filter element integration assembly 5, and the filter element integration assembly 5 is provided with a filtrate collection chamber 6 , the bottom plate of the pressure vessel 1 is provided with a filtrate collection pipe 7, and each filtrate collection chamber 6 is...

specific Embodiment 2

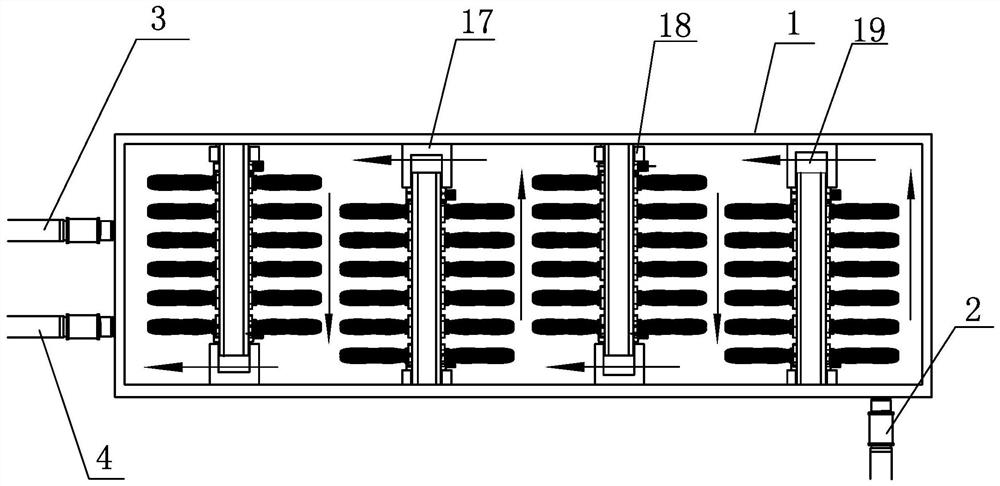

[0048] A curtain type membrane module vertical cross-flow filtration integrated device, such as Figure 6 , Figure 7 and Figure 8 As shown, the pressure vessel 1 comprising a cube structure is provided with a raw material liquid inlet 2 at the lower end of the left side of the pressure vessel 1, a concentrated liquid outlet 3 is arranged at the upper end of the right side of the pressure vessel 1, and a waste liquid is provided at the lower end of the right side of the pressure vessel 1. Outlet 4, at least one filter element assembly 5 is arranged in the pressure vessel 1, the flow direction of the material liquid in the pressure vessel 1 is vertically around the filter membrane surface of the filter element assembly 5, and the filter element assembly 5 is provided with a filtrate collection chamber Chamber 6, the bottom plate of the pressure vessel 1 is provided with a filtrate collection pipe 7, and each filtrate collection chamber 6 is respectively connected with the fil...

specific Embodiment 3

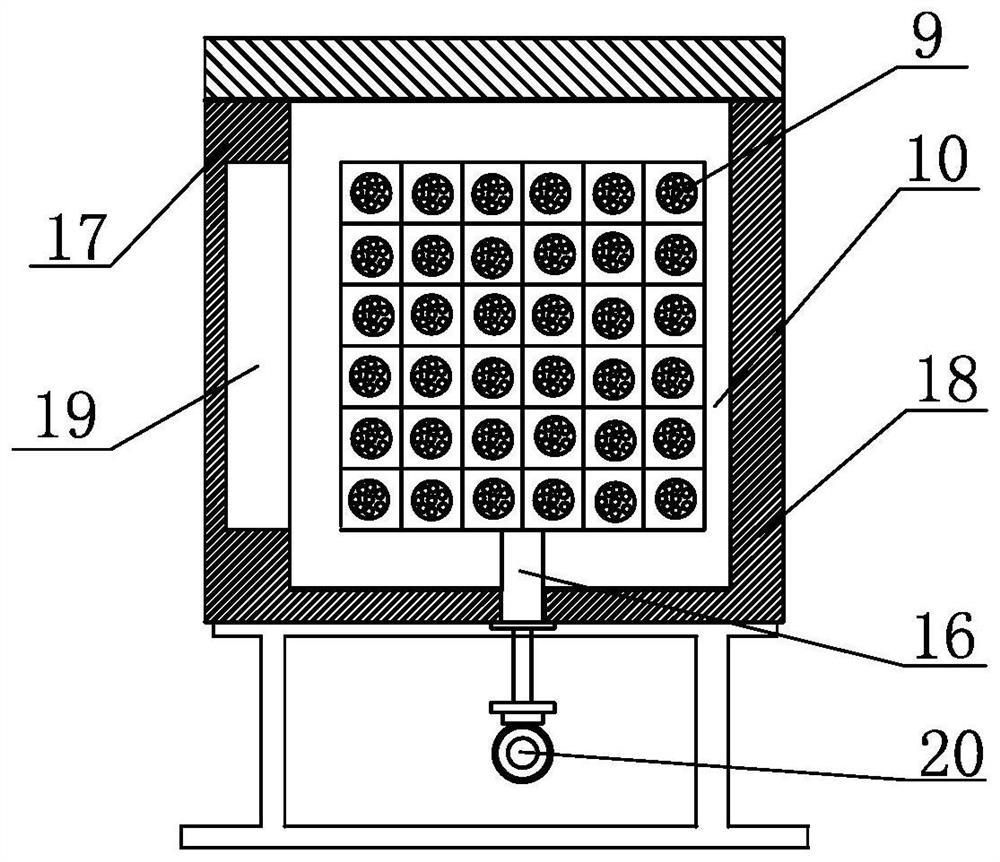

[0055] When it is necessary to increase the membrane filtration area of the equipment, the above-mentioned cross-flow filtration membrane module can also be used according to Figure 9 Integrate as shown. The structure is the same as that of the above-mentioned specific embodiment 2, and the difference is that the pressure vessel 1 is divided into several cavities 26 by longitudinal partitions 25, and several curtain membrane modules are evenly arranged side by side in each cavity 26, and the curtain membrane modules The upper and lower ends of the upper and lower ends are respectively provided with a filtrate collection chamber 6, and the lower end of the filtrate collection chamber 6 is connected with an outlet pipe 24, and the outlet pipe 24 passes through the bottom plate of the pressure vessel 1 and communicates with the filtrate collection pipe 7. The longitudinal partition 25 is provided with a second filtrate return channel 27 for allowing the filtrate to flow throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com