Water washing flotation machine capable of efficiently discharging and separating sludge and working method thereof

A discharge and flotation machine technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of triangular belts that cannot be transferred, poor use effect, and burnt motors, etc., to improve the application level of classification, The effect of improving work efficiency and overcoming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

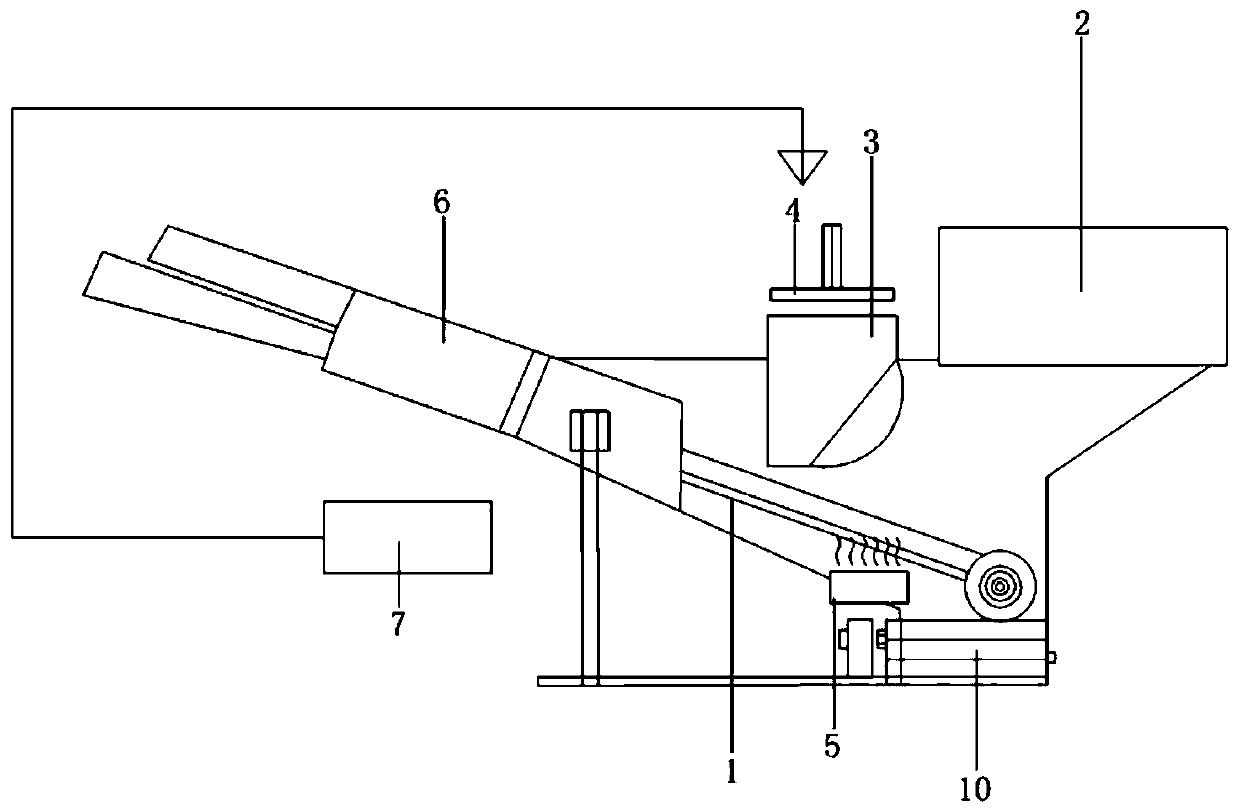

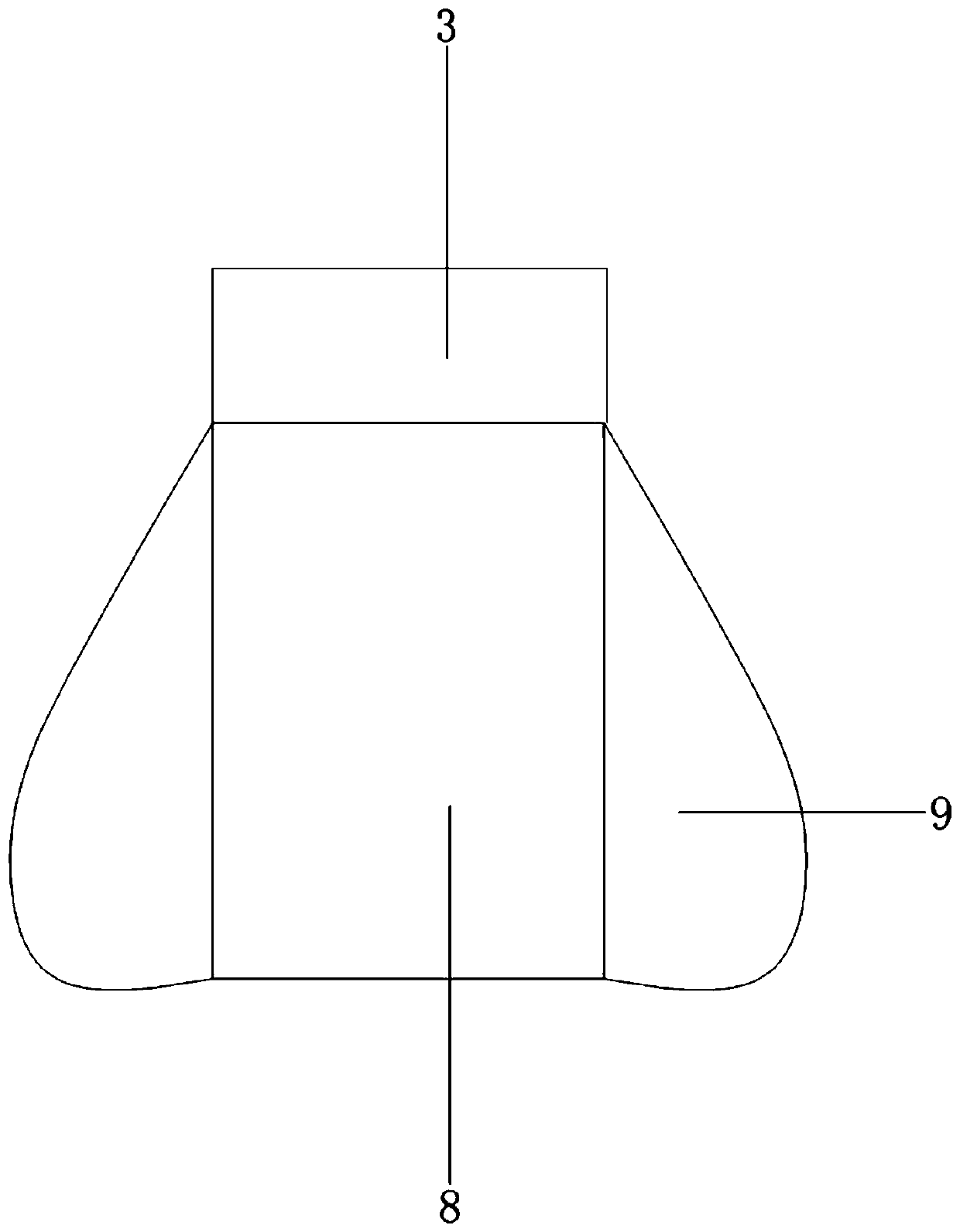

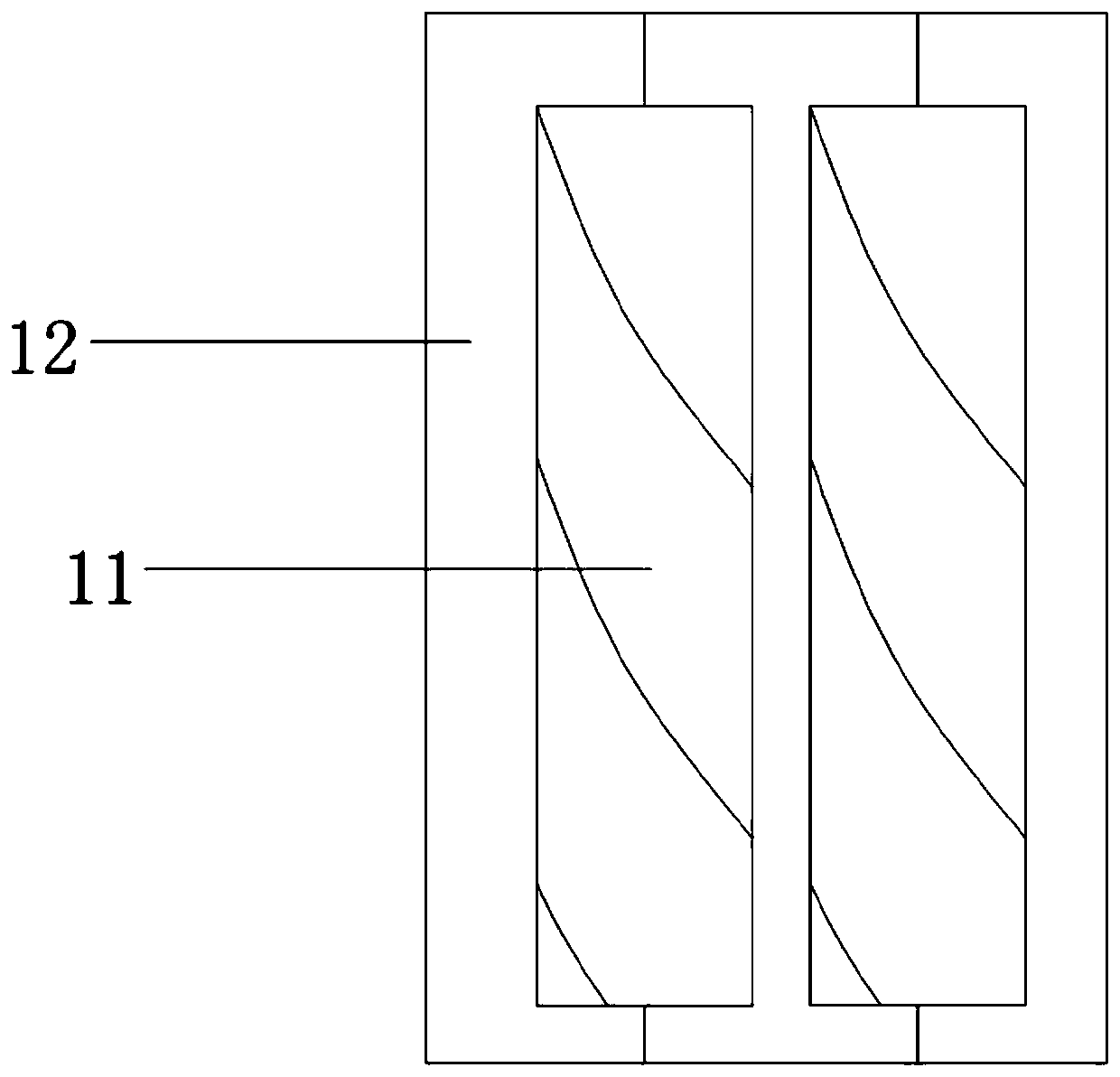

[0036] A water washing flotation machine for efficient sewage discharge and discharge classification, including a heavy material conveyor 1 immersed in water and a light material collector 2 attached to the water surface, and a feeding cylinder 3 partially immersed in water is arranged above the heavy material conveyor 1. The top of the feeding cylinder 3 is provided with a lifting pressure plate 4, and the bottom of the heavy material conveyor 1 below the feeding cylinder 3 is provided with an aeration mechanism 5, and the gas generated by the aeration mechanism passes through the heavy material conveyor 1 and can The light material is driven to move upward, the output end of the heavy material conveyor 1 is connected to the vibrating screen 6, and the collecting box 7 is arranged under the vibrating screen, and the collecting box 7 is connected to the feeding cylinder 3 through the conveying mechanism.

[0037] The above-mentioned structures are all arranged in the case. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com