Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of high energy, mass production and wide use, high cost of high-energy ion implantation equipment, etc., to save manufacturing Cost, the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

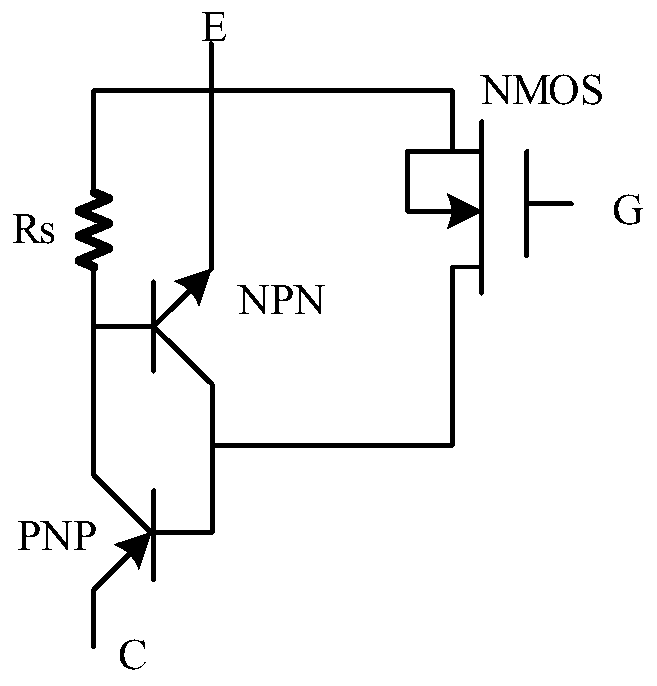

[0017] IGBT (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) is composed of BJT (Bipolar Junction Transistor, bipolar transistor) and MOS (Metal Oxide Semiconductor, metal-oxide-semiconductor / insulated gate field effect transistor) The composite fully controlled voltage-driven power semiconductor device is a switch that is either on or off. The IGBT does not have the function of amplifying the voltage. It can be regarded as a wire when it is turned on, and it is regarded as an open circuit when it is turned off.

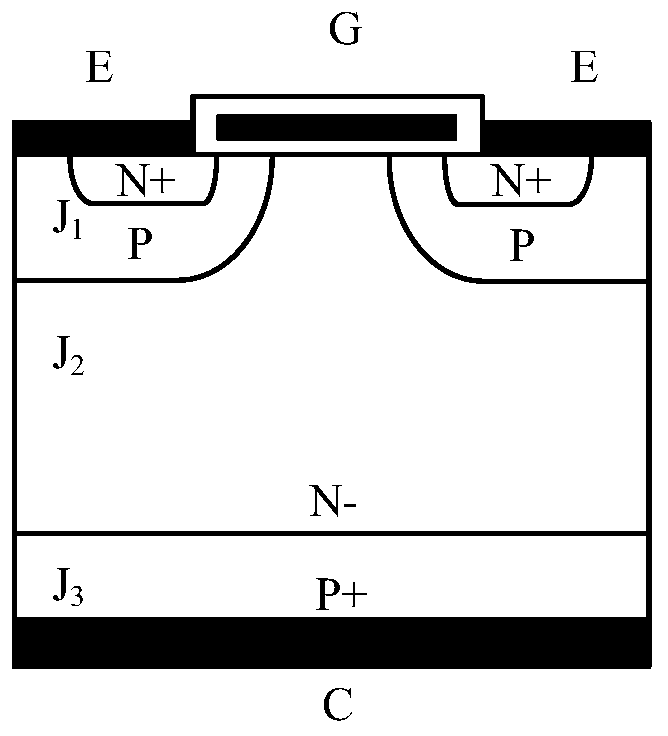

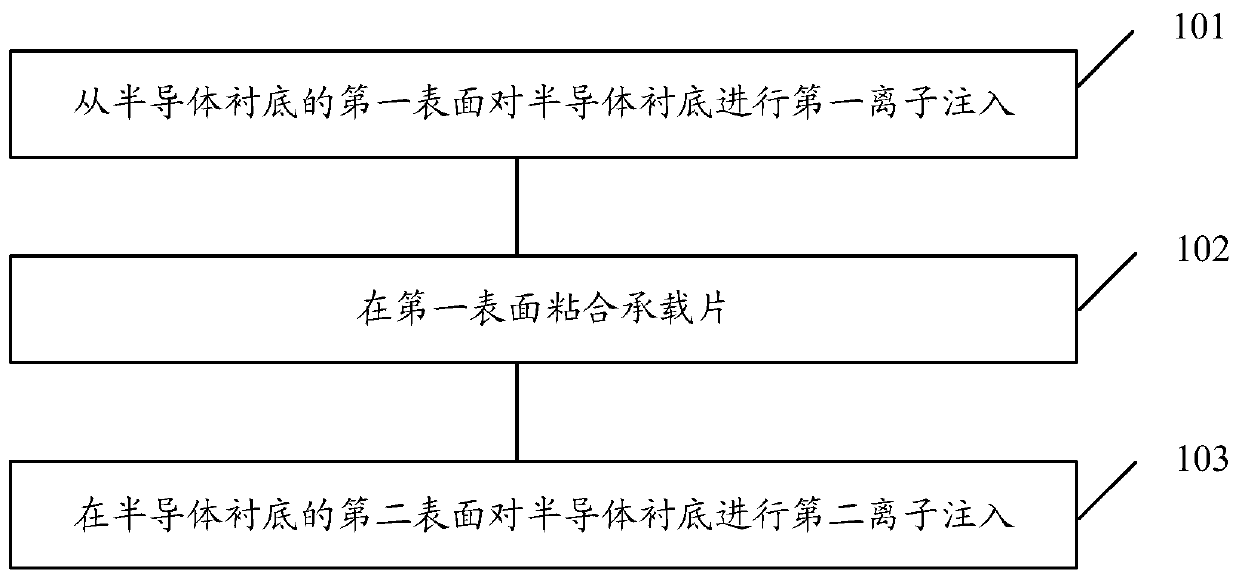

[0018] figure 1 It is a structural schematic diagram of an IGBT device in an embodiment, such as figure 1 As shown, the IGBT device is a vertical device, and the thickness can reach 6mil (mil). The bottom layer of the IGBT device is the J3 layer, the substrate made of semiconductor material is formed by P-type heavy doping, and the J3 layer is connected with the collector C made of metal material. The J2 layer above the J3 layer is formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com