Camera module

A technology of camera module and lens module, which is applied in the direction of image communication, TV, color TV parts, etc., can solve the problems of inability to obtain resolution and poor imaging effect, achieve excellent image quality and facilitate miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

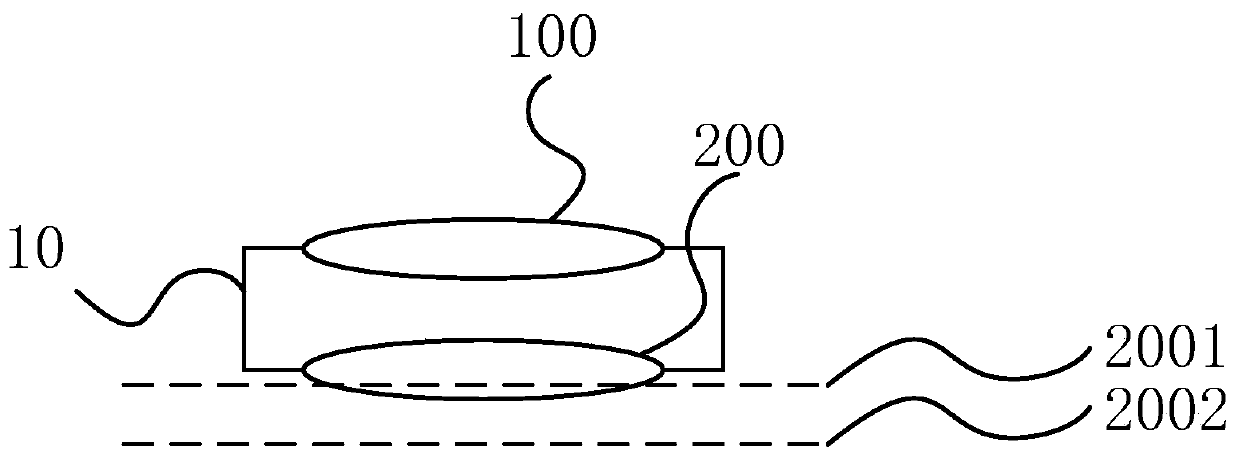

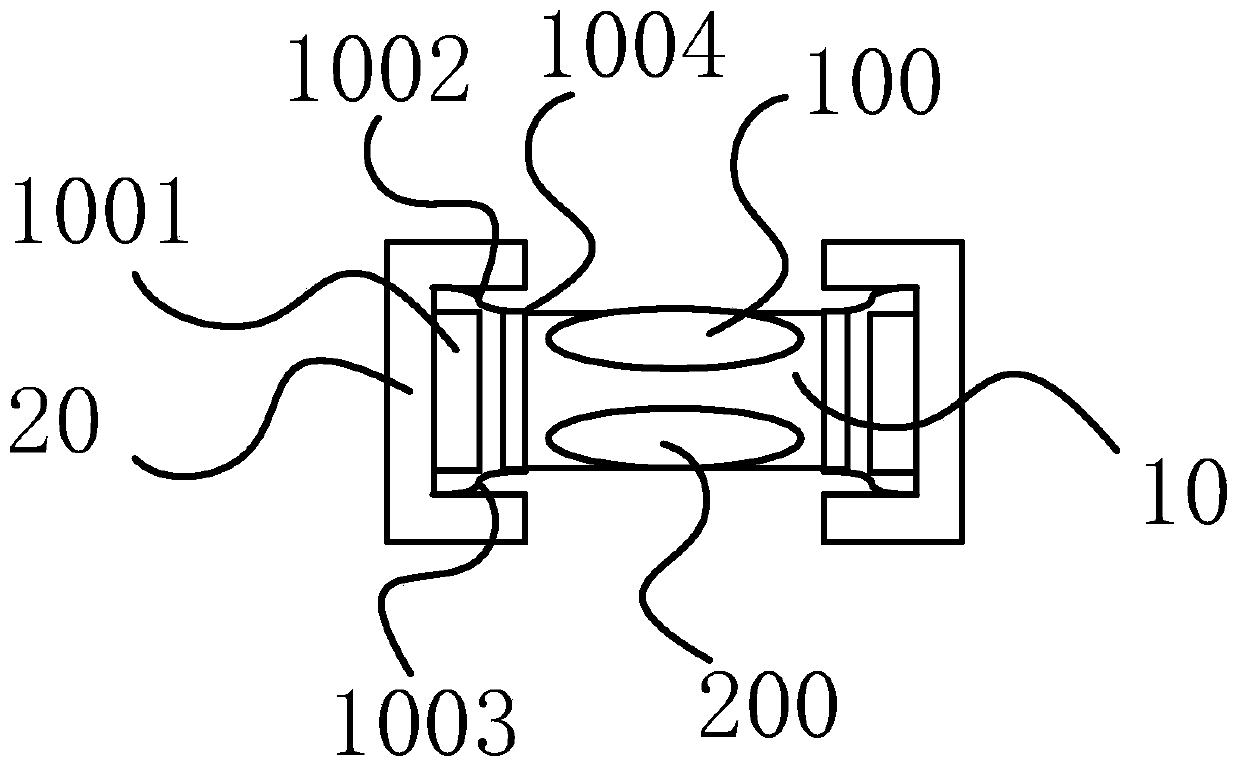

[0193] The first embodiment of the present invention Image 6 Shown. The first lens group 100 includes 4 lenses, and the second lens group 200 includes 5 lenses. The above 9 lenses are all aspherical lenses. The surface shape of the aspheric lens is represented by the curve equation as follows (the aspheric surface is formed by the curve revolving around the optical axis):

[0194]

[0195] among them:

[0196] X: The point on the aspheric surface that is Y from the optical axis, and its relative distance from the tangent to the focal point on the aspheric surface;

[0197] Y: the vertical distance between the point on the aspherical curve and the optical axis;

[0198] r: radius of curvature;

[0199] k: conic coefficient;

[0200] A i : Aspheric coefficient of order i.

[0201] The parameters of each surface of the lens in this embodiment are as Picture 12 with Figure 13 Shown.

[0202] Picture 12 The units of the length-type physical quantities such as the radius of curvature r an...

no. 2 example

[0207] The second embodiment of the present invention Figure 7 Shown. The first lens group 100 includes 4 lenses, and the second lens group 200 includes 4 lenses. The parameters of each surface of the lens in this embodiment are as Figure 14 with Figure 15 As shown, the variable definition is similar to the foregoing, and will not be repeated.

[0208] The object surface of the first lens of the first lens group 100 of this embodiment is an aspheric surface, and the curved surface is a concave surface near the optical axis, and there is an inflection point after the curved surface is a distance away from the optical axis, and the image side surface is non-spherical. The spherical surface is concave; the object surface of the second lens is aspherical, and it is convex near the optical axis, and the image surface is concave. The second lens appears to be thicker in the center than the periphery; the object of the third lens The square surface is also concave, but the degree of...

no. 3 example

[0212] The third embodiment of the present invention Figure 8 As shown, the first lens group 100 includes 3 lenses, and the second lens group 200 includes 4 lenses. The parameters of each surface of the lens in this embodiment are as Figure 16 with Figure 17 As shown, the variable definition is similar to the foregoing, and will not be repeated.

[0213] The object surface of the first lens of the first lens group 100 of this embodiment is an aspheric surface, and the curved surface is a concave surface near the optical axis, and there is an inflection point after the curved surface is a distance away from the optical axis, and the image side surface is non-spherical. The convex surface of the spherical surface; the object surface of the second lens is an aspheric convex surface, and the image surface is an aspheric concave surface; the object surface and image surface of the third lens are both aspheric convex surfaces.

[0214] The object side and image side surfaces of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com