Method for detecting deviation of loading capacity of capsule preparation

A detection method and capsule technology, applied in capsule delivery, pharmaceutical formulations, complex mathematical operations, etc., can solve problems such as traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

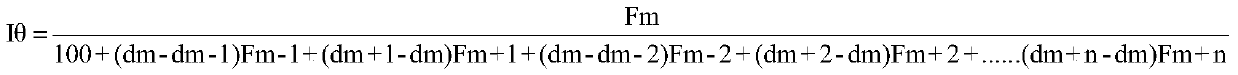

[0059] Example-1: Quantitative prediction of loading deviation of capsule preparations based on intermediate physical properties

[0060] In this implementation case, the physical properties of 25 batches of Guizhi Fuling capsule intermediates were used, and the partial least squares model was used to quantitatively predict the deviation of the filling capacity of the capsule preparation. The intermediates are soft material fine powder, wet granules, dry granules, sized granules and blended granules. The preparation process of the capsule preparation is shown in Example 3.

[0061] 1. Sample collection

[0062] Collect Guizhi Fuling capsule production process intermediates (preparation batch numbers: 180610, 180611, 180612, 180613, 180614, 180701, 180702, 180703, 180702, 180801, 180802, 180803, 180804, 180805, 180806, 180808, 1808081 , 180811, 180812, 180813, 180814, 180815, 180816) produced by Jiangsu Kangyuan Pharmaceutical Co., Ltd.

[0063] 2. Determination of Physical ...

Embodiment -2

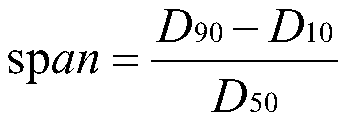

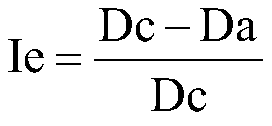

[0108] Example-2: Prediction of the deviation of capsule preparation loading based on multiple linear regression model

[0109] Two key material attributes of 25 batches of Guizhi Fuling capsules were selected, and multiple linear regression model was used to predict the filling deviation of Guizhi Fuling capsules. The key material attribute described is the median particle size value (D 50 ) and the percentage of whole particles smaller than 50 μm. The study found that the above two physical quality attributes have a significantly higher impact on the capsule preparation granulation filling process than other physical quality attributes, and can effectively reduce noise and obtain more accurate prediction results.

[0110] 1. Sample collection

[0111] Collect Guizhi Fuling capsule production process intermediates (preparation batch numbers: 180610, 180611, 180612, 180613, 180614, 180701, 180702, 180703, 180702, 180801, 180802, 180803, 180804, 180805, 180806, 180808, 180808...

Embodiment -3

[0133] Embodiment-3: A kind of preparation method of capsule preparation with stable loading difference

[0134] Taking Guizhi Fuling Capsules as an example, the preparation method of the capsule preparation of the present invention is as follows:

[0135] Take Poria cocos and crush it into fine powder; Moutan cortex is steam distilled, collect the distillate, separate the volatile components, and set aside; use 90% ethanol to extract the dregs, cassia twig, white peony root, peach kernel and the remaining poria cocos twice with 90% ethanol and combine The extract is recovered from ethanol until there is no yeast smell, concentrated under reduced pressure to an appropriate amount; the dregs of the medicine are decocted twice with water, filtered, and the filtrate is combined, concentrated under reduced pressure to an appropriate amount, and the above two concentrated solutions are mixed with Poria cocos fine powder, After drying and mixing, it becomes soft material fine powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com