Hydrogenation catalyst and preparation method and application thereof and hydrogenation refining method

A hydrogenation catalyst and catalyst technology, which are applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low hydrogenation catalyst activity, complex preparation process, poor controllability, etc., and achieve savings Start-up cycle, high catalytic performance, and the effect of improving hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The second aspect of the present invention provides a kind of preparation method of hydrogenation catalyst, and this preparation method comprises the following steps:

[0046] (1) The carrier is impregnated with tetrathiotungstate solution, and dried to obtain solid A;

[0047] (2) The solid A is impregnated with a solution containing a Group VIII metal salt, and then heat-treated in an inert atmosphere or a reducing atmosphere to obtain a hydrogenation catalyst. The heat treatment makes the tungsten element in the hydrogenation catalyst exist in the form of trisulfide, Group VIII metal elements exist in the form of salts.

[0048] The third aspect of the present invention provides a kind of preparation method of hydrogenation catalyst, and this preparation method comprises the following steps:

[0049] (1) The carrier is impregnated with a tetrathiotungstate solution, and then heat-treated in an inert atmosphere or a reducing atmosphere to obtain a composite material ...

Embodiment approach

[0064] In the present invention, in order to obtain a better water-soluble effect of the tungsten-containing compound, a co-solvent can be added appropriately. According to a preferred embodiment of the present invention, the method further includes introducing a co-solvent into step a), and the co-solvent is selected from at least one of ammonia water, phosphoric acid and oxalic acid. In the present invention, there is no special limitation on the addition amount of the co-solvent, as long as a better water-soluble effect can be obtained.

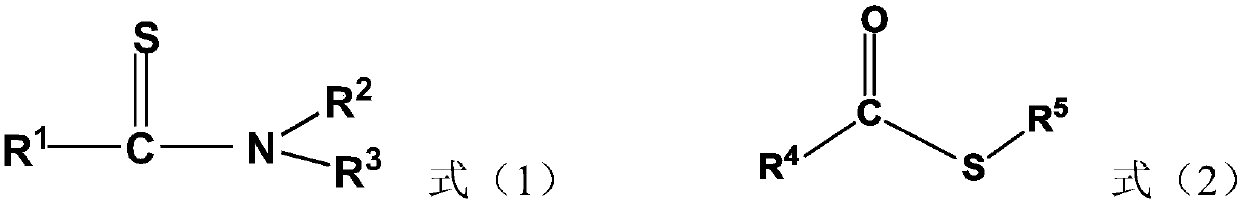

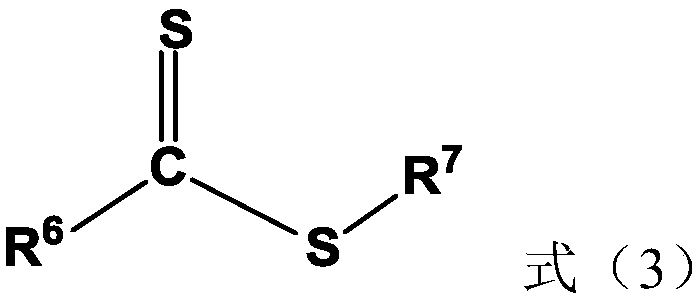

[0065] The present invention has a wide range of options for the amount of organic sulfur source and tungsten-containing compound, as long as the molar ratio of the organic sulfur source calculated as sulfur element to the tungsten-containing compound calculated as metal element is not less than 2, preferably 2.5- 5:1, more preferably 3-4:1. Adopting this preferred embodiment can not only meet the reaction requirements of the two, but als...

Embodiment I-1

[0115] (1) Preparation of tetrathiotungstate solution

[0116] Mix sodium tungstate with water, stir for 40 minutes, add thioacetamide, stir for 30 minutes, and prepare 100 mL of sodium tungstate containing 0.25 mol / L (in WO 3 To a solution of 1mol / L thioacetamide, add ammonia water to adjust the pH to 9, under airtight conditions, heat it to 85°C for 10h, then concentrate it to 15mL; UV- Vis test, analysis shows that WS in solution 4 2- The existence of , proves that the substance obtained by the reaction is a tetrathiotungstate solution. In addition, the solution changes from colorless to orange at the beginning, which further proves that WS 4 2- The presence.

[0117] (2) Preparation of hydrogenation catalyst

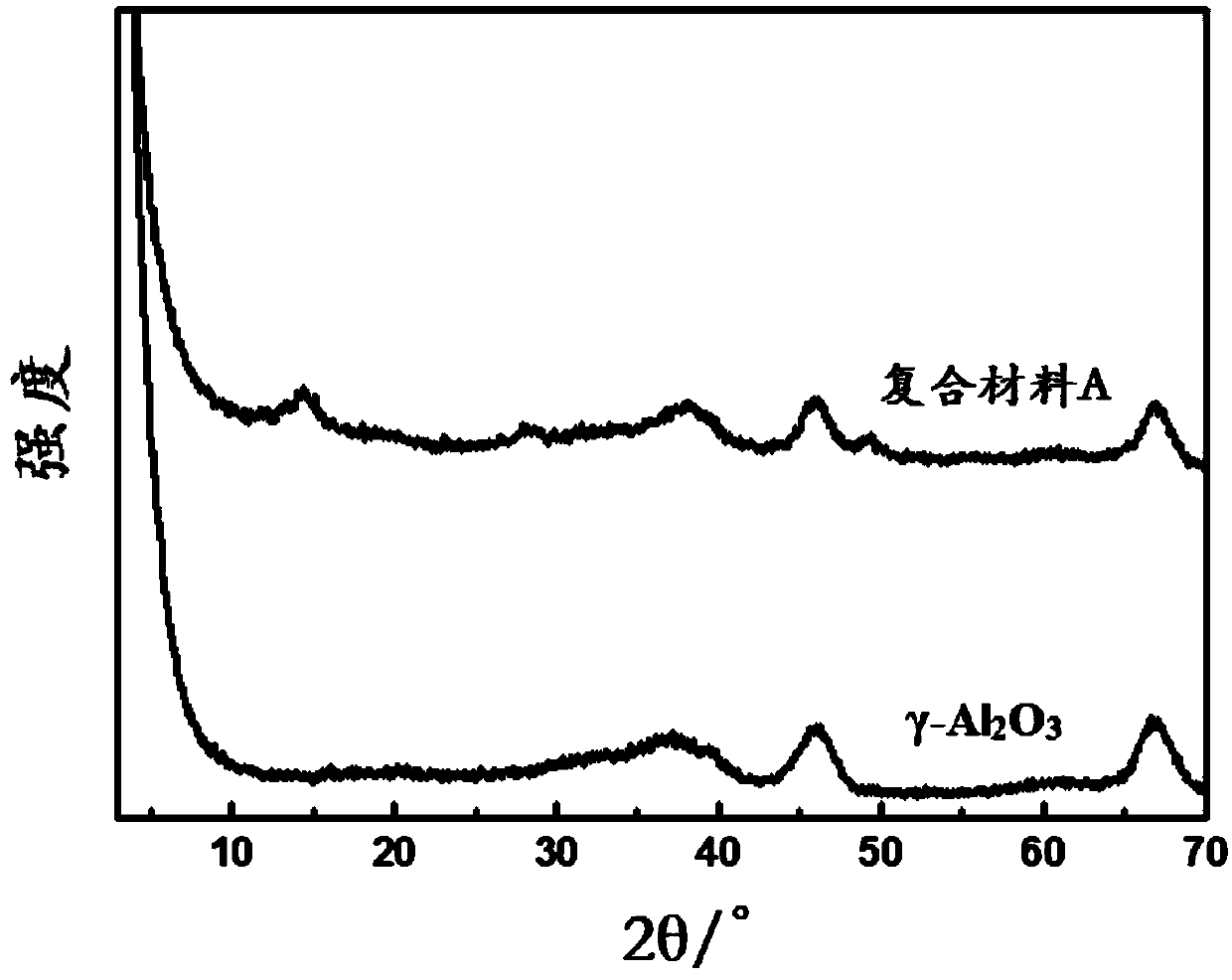

[0118] Saturated and impregnated the above tetrathiotungstate solution in 20g of γ-Al with a diameter of 1-3mm 2 o 3 Carrier (specific surface area 251m 2 / g, the pore volume is 0.75mL / g, the same below, the XRD pattern is as follows figure 1 shown), the imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com