A servo tool changer

A technology of tool changing device and tool changing mechanism, which is applied in positioning devices, manufacturing tools, tool holders, etc., and can solve the problems of many parts, heavy hydraulic pump workload, and accelerated loss of internal parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

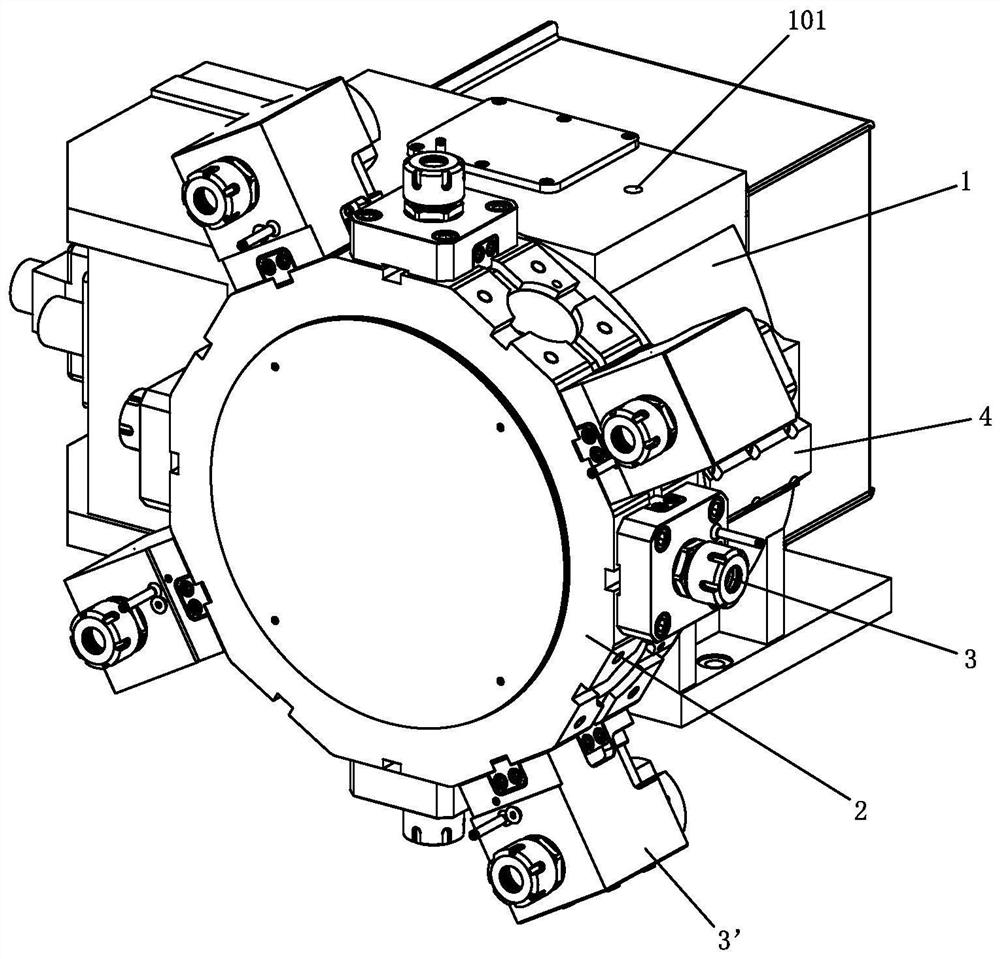

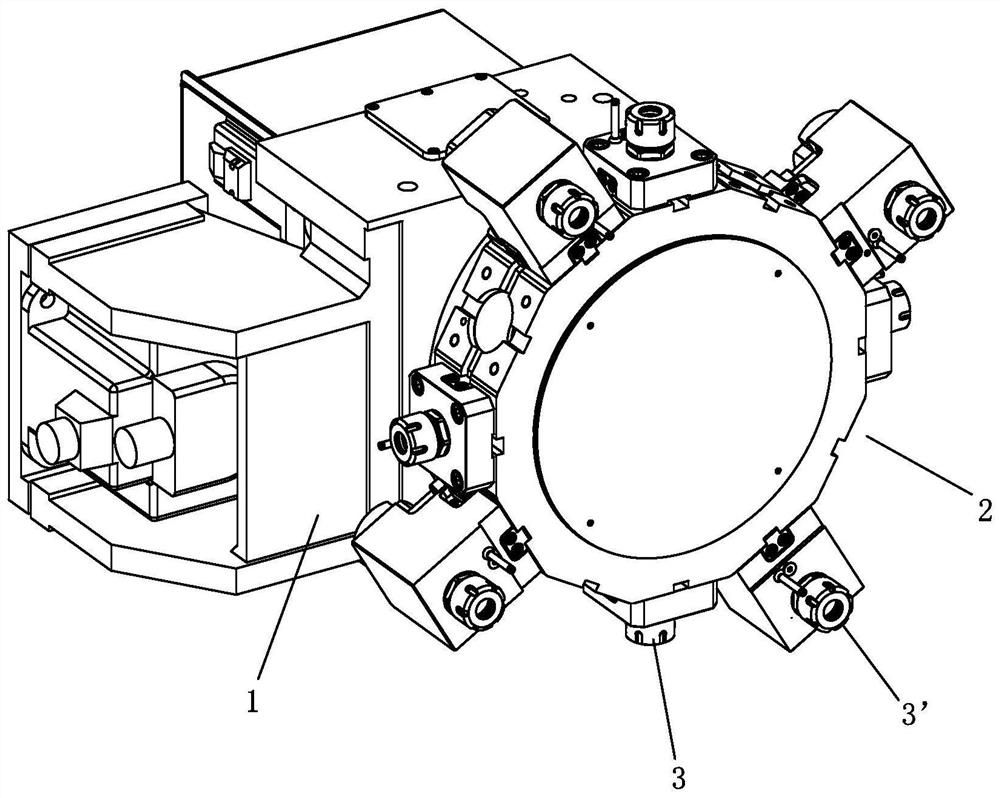

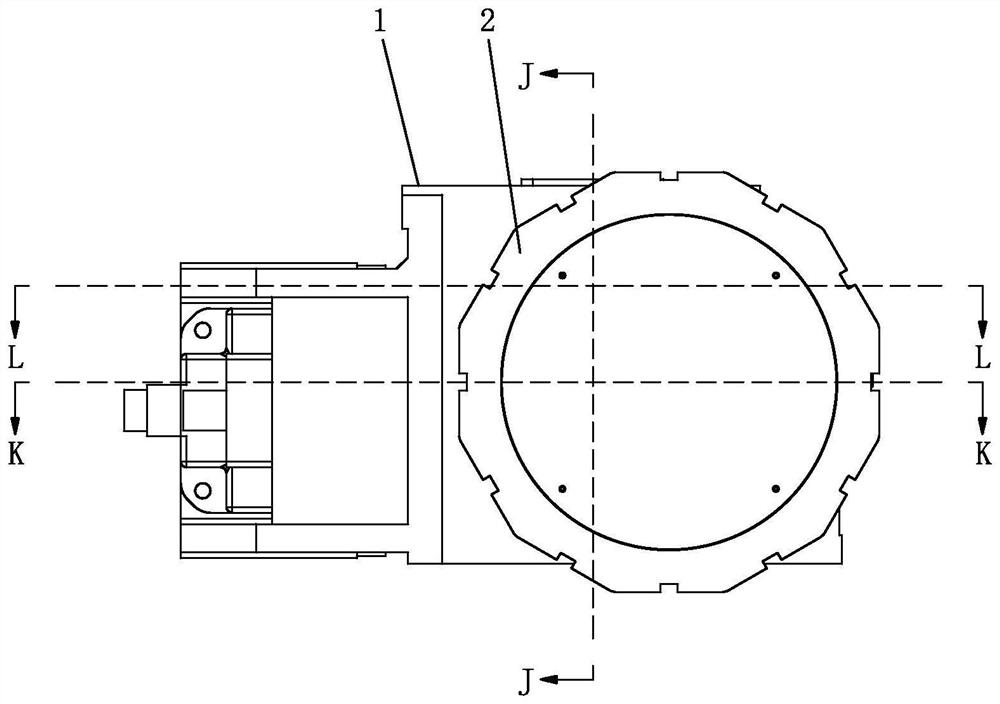

[0038] see Figure 1-Figure 15 , the servo tool changer, including

[0039] The tool change mechanism, the tool change mechanism includes a fixed box 1, and a power tool holder 2 for radially and detachably installing more than one set of tool holders. The powered tool holder 2 is rotatably arranged on the fixed box 1; the fixed box The inner side of 1 is fixed with a fixed toothed disc 4; the end surface of the power tool holder 2 is provided with a rotating toothed disc 5, which can drive the powered tool holder 2 to rotate relative to the fixed box 1 by rotating the toothed disc 5, so as to achieve the tool change effect; The knife mechanism also includes a linkage toothed disc 6 that is movable relative to the fixed box body 1 and the driven tool holder 2, and the linked toothed disc 6 moves axially relative to the fixed box body 1 and the driven t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com