Electric drive fin stabilizer with speed reducer

A technology with reducer and fin stabilizer, which is applied in the direction of using hydrofoils to act on the surrounding water surface to reduce the movement of ships. It can solve the problems of limited slewing mechanism selection and the inability to guarantee equipment reliability, so as to reduce equipment quality and improve energy efficiency. Shake effect, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The scheme will be further described below in conjunction with the accompanying drawings and embodiments.

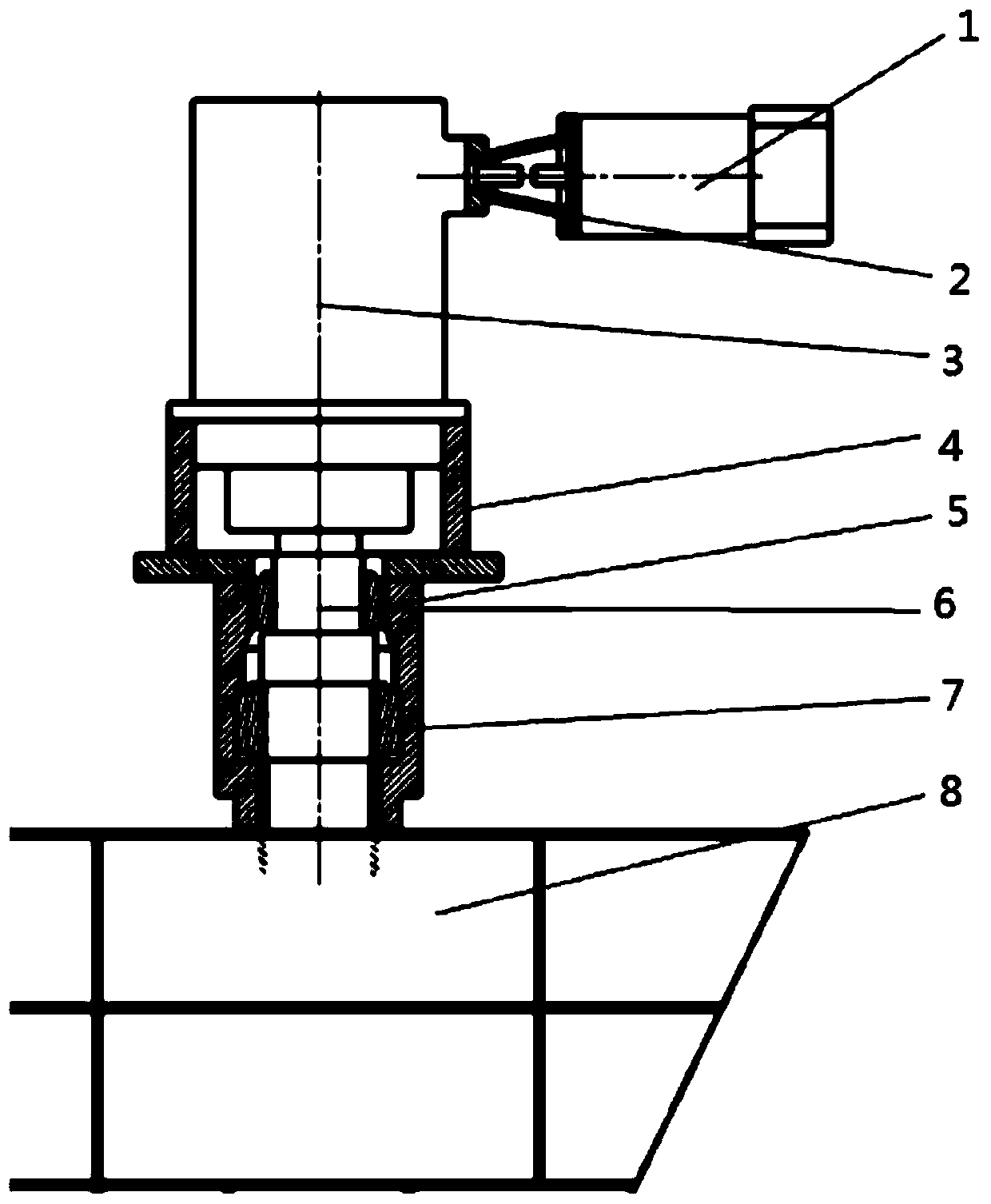

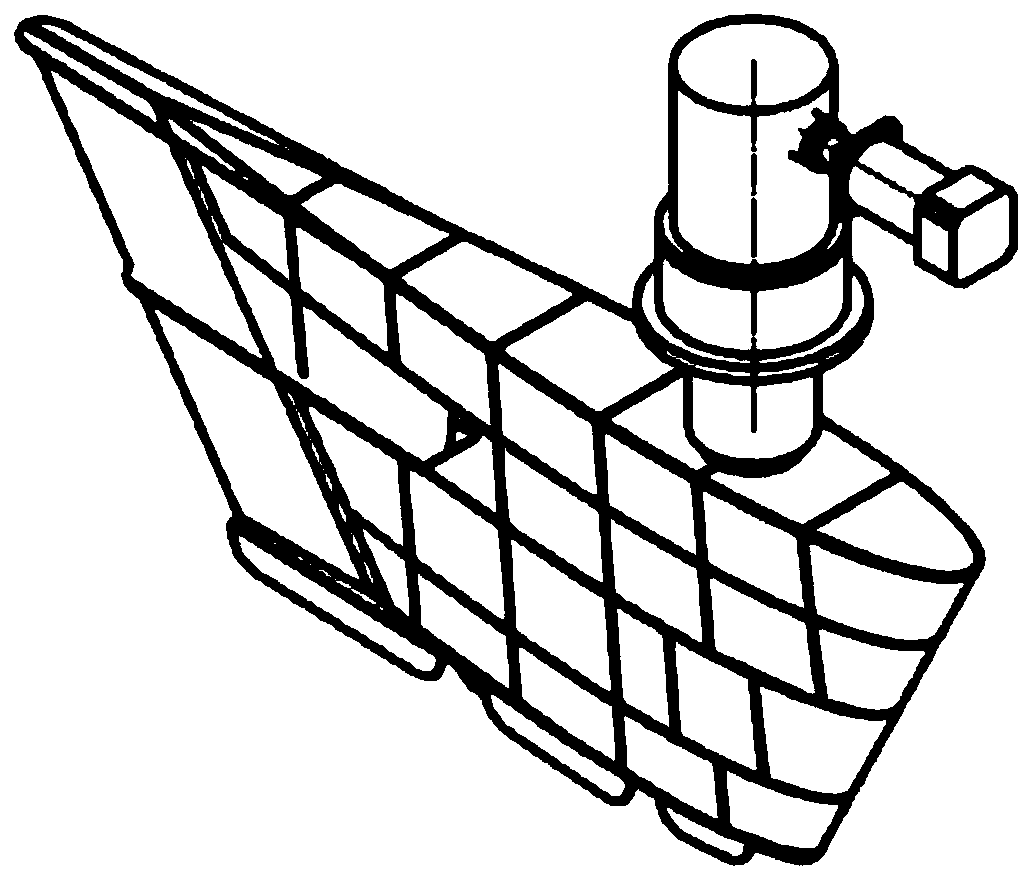

[0019] Such as figure 1 , as shown in 2, an electric drive fin stabilizer with reducer, including servo motor 1, planetary gear reducer 3, support seat 4, tapered roller bearing A5, fin shaft 6, tapered roller bearing B7, fin Leaf 8, frequency converter, driver, control box. The servo motor 1 is connected with the right-angle planetary gear reducer 3 through the mounting flange 2; the planetary gear reducer 3 is installed on the support seat 4 through the flange; the fin shaft 6 is connected with the planetary gear reducer 3 through a spline connection; the fin The shaft 6 is arranged in the support seat 4 through the tapered roller bearing A5 and the tapered roller bearing B7, and the tapered roller bearing A5 and the tapered roller bearing B7 are arranged back to back inside the support seat, and the fin blade 8 and the fin shaft 6 pass through the taper. A ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com