A kind of marine oil composite agent, its preparation method and application

A technology for marine oil and compounding agent, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems that the water separation performance and general quality performance of the base oil cannot be effectively improved, and achieve the effect of improving water separation performance and good appearance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

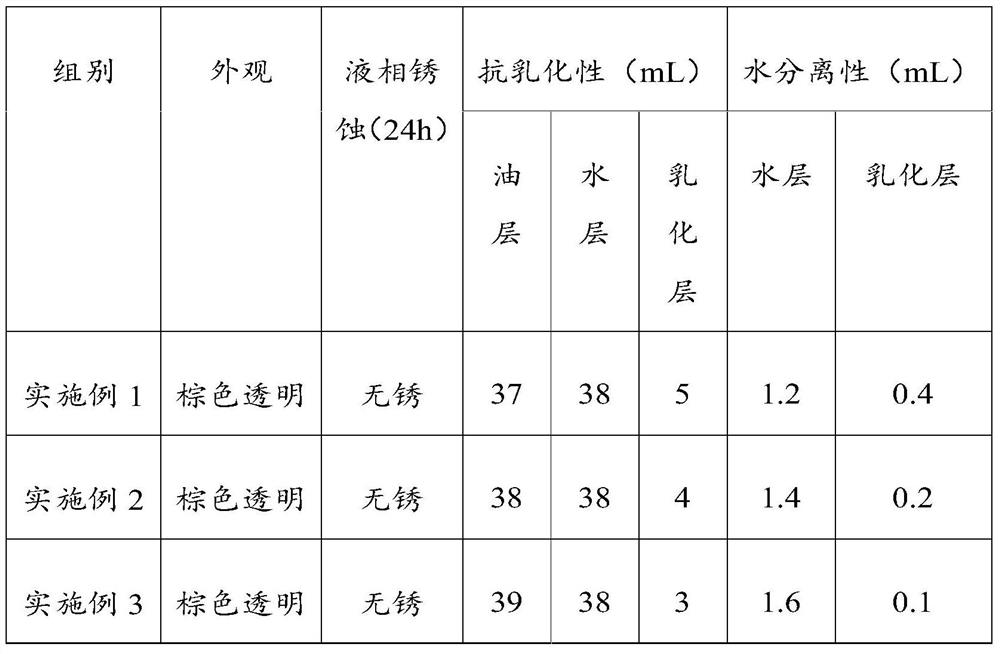

Examples

Embodiment 1

[0033] The present embodiment provides a kind of marine oil compounding agent, and its raw material comprises high alkali value calcium sulfonate (TBN400) 35%, sulfurized alkylphenate calcium (TBN150) 22%, p-dialkyl dithiophosphoric acid in terms of mass fraction Zinc 5%, polyisobutylene succinimide 25%, low base number calcium alkyl salicylate (TBN75) 5.5% and mineral oil 7.5%.

[0034] This embodiment also provides a preparation method of a marine oil compounding agent, comprising: using the above-mentioned raw materials in this embodiment according to the formula of high alkali value calcium sulfonate, sulfurized alkylphenate calcium (TBN150), p-dialkyldithiophosphoric acid Zinc, polyisobutylene succinimide, low base number calcium alkyl salicylate and mineral oil were added sequentially and mixed for 3 hours at a temperature of 60°C.

Embodiment 2

[0036] This embodiment provides a kind of marine oil compounding agent, and its raw material comprises high base value calcium sulfonate (TBN400) 35%, sulfurized alkylphenate calcium (TBN150) 22%, dialkyl dithiophosphate zinc 5%, polyisobutylene succinimide 25%, low base number calcium alkyl salicylate (TBN80) 5.5% and mineral oil 7.5%.

[0037] This embodiment also provides a method for preparing a bunker oil compounding agent, comprising: adding the above-mentioned raw materials in this embodiment in sequence, and mixing at a temperature of 80° C. for 1 hour.

Embodiment 3

[0039]The present embodiment provides a kind of marine oil compounding agent, and its raw material comprises low base value calcium sulfonate (TBN30) 10%, neutral base value calcium sulfonate (TBN300) 10%, high base value calcium sulfonate (TBN400) 15%, sulfurized calcium alkylphenate (TBN150) 22%, zinc dialkyldithiophosphate 5%, polyisobutylene succinimide 25%, low base value calcium alkyl salicylate (TBN60) 5.5% and mineral oil 7.5%.

[0040] This embodiment also provides a method for preparing a bunker oil compounding agent, comprising: adding the above-mentioned raw materials in this embodiment in sequence, and mixing at a temperature of 70° C. for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com