An environment-friendly long-term storage anti-rust oil composition and its preparation method

A technology of anti-rust oil and composition, which is applied in the preparation of environment-friendly long-term storage anti-rust oil composition, environment-friendly long-term storage anti-rust oil composition, and the field of anti-rust oil, which can solve the problem of outer packaging pollution and dryness , oily workpiece and other problems, to achieve the effect of easy removal, low fuel consumption and good penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

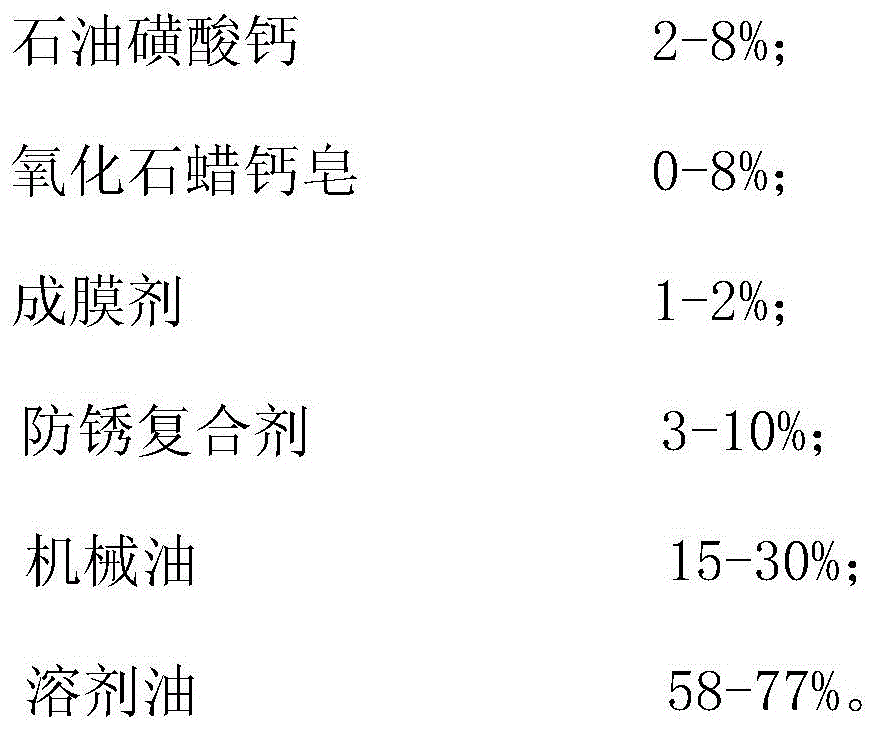

Method used

Image

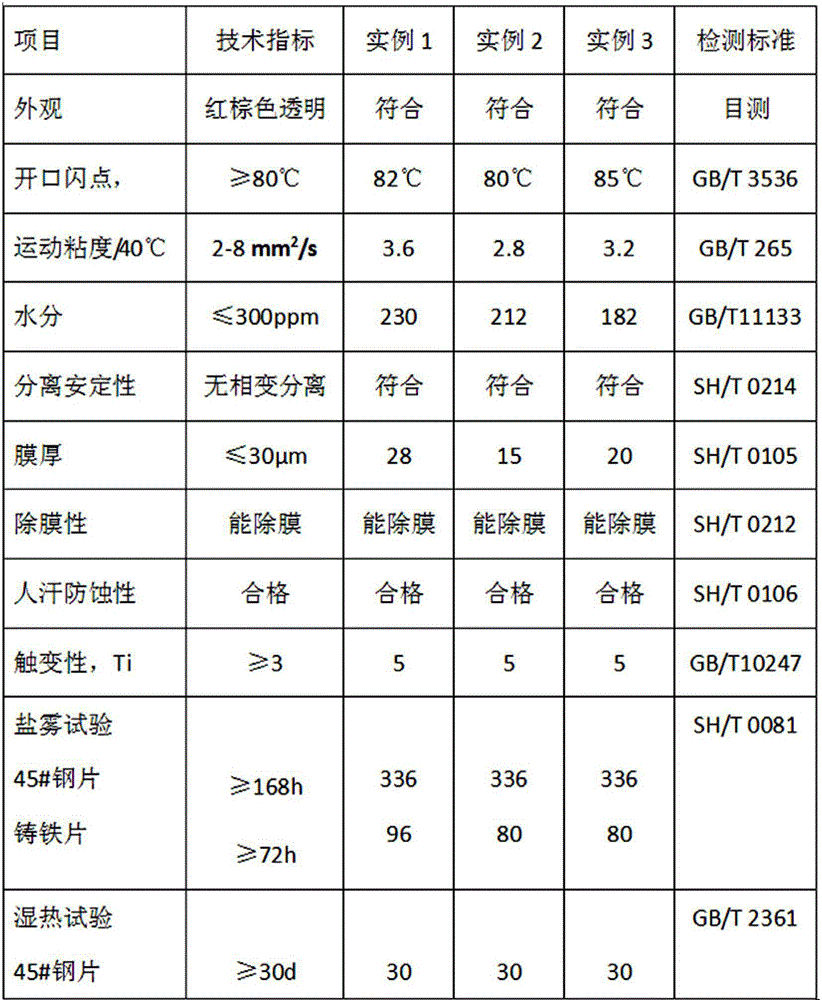

Examples

Embodiment 1

[0027] 1. Preparation of antirust composite agent: Add 2.5 kg of palmitic acid and 5 kg of petroleum sulfonic acid into the reactor, heat up to 80 degrees Celsius, stir evenly, add 0.7 kg of calcium hydroxide, stir evenly, heat up to 100 degrees Celsius, and react for 1 hour , get anti-rust compound agent.

[0028] Two, the preparation of antirust oil composition:

[0029] (1) First, add 30 kilograms of paraffin base oil with a kinematic viscosity of 5-100cst into the blender and heat up to 100 degrees Celsius;

[0030] (2) Then, add 1 kg of ethylene propylene rubber, add 0.1 kg of dioctyl sebacate, 1 kg of hydrogenated castor oil, and stir for 30 minutes;

[0031] (3) Then, add the antirust composite agent that step 1 prepares, add 4 kilograms of oxidized paraffin calcium soaps, add 5 kilograms of petroleum calcium sulfonates, stir 30 minutes;

[0032] (4) Finally, lower the temperature to 40 degrees Celsius, add 60 kg of dearomatized oil with a kinematic viscosity of 0.5-3...

Embodiment 2

[0035] 1. Preparation of anti-rust composite agent: Add 5 kg of palmitic acid and 5 kg of petroleum sulfonic acid into the reactor, heat up to 80 degrees Celsius, stir evenly, add 1.1 kg of calcium hydroxide, stir evenly, heat up to 100 degrees Celsius, and react for 1 hour , get anti-rust compound agent.

[0036] Two, the preparation of antirust oil composition:

[0037] (1) First, add 20 kg of mechanical oil to the blender and raise the temperature to 100 degrees Celsius;

[0038] (2) Then, add 1 kg of ethylene propylene rubber, add 0.1 kg of dioctyl sebacate, 0.5 kg of hydrogenated castor oil, and stir for 30 minutes;

[0039] (3) Then, add 3 kilograms of antirust compound agents that step 1 prepares, add 6 kilograms of oxidized paraffin calcium soaps, add 5 kilograms of petroleum calcium sulfonates, stir 30 minutes;

[0040] (4) Cool down to 40 degrees Celsius, add 70 kg of solvent oil, and stir for 30 minutes to obtain a thin long-lasting antirust oil.

[0041] The ant...

Embodiment 3

[0043] 1. Preparation of anti-rust composite agent: Add 5 kg of palmitic acid and 5 kg of petroleum sulfonic acid into the reactor, heat up to 80 degrees Celsius, stir evenly, add 1.1 kg of calcium hydroxide, stir evenly, heat up to 100 degrees Celsius, and react for 1 hour , get anti-rust compound agent.

[0044] Two, the preparation of antirust oil composition:

[0045] (1) First, add 30 kg of mechanical oil to the blender and raise the temperature to 100 degrees Celsius;

[0046] (2) Then, add 1 kg of ethylene propylene rubber, add 0.1 kg of dioctyl sebacate, 1 kg of hydrogenated castor oil, and stir for 30 minutes;

[0047] (3) Then, add 2.5 kilograms of antirust composites prepared by step 1, add 4 kilograms of oxidized paraffin calcium soap, add 3 kilograms of petroleum calcium sulfonate, stir 30 minutes;

[0048] (4) Finally, cool down to 40 degrees Celsius, add 60 kg of solvent oil, and stir for 30 minutes to obtain a thin long-lasting antirust oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com