Hydraulic oil for construction machinery

A technology of engineering machinery and oil pressure, which is applied in the field of hydraulic operating oil for engineering machinery, can solve the problems of small friction coefficient and large pressing force, and achieve the effects of improving lubrication performance, prolonging service life, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

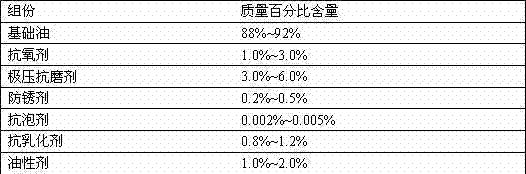

Method used

Image

Examples

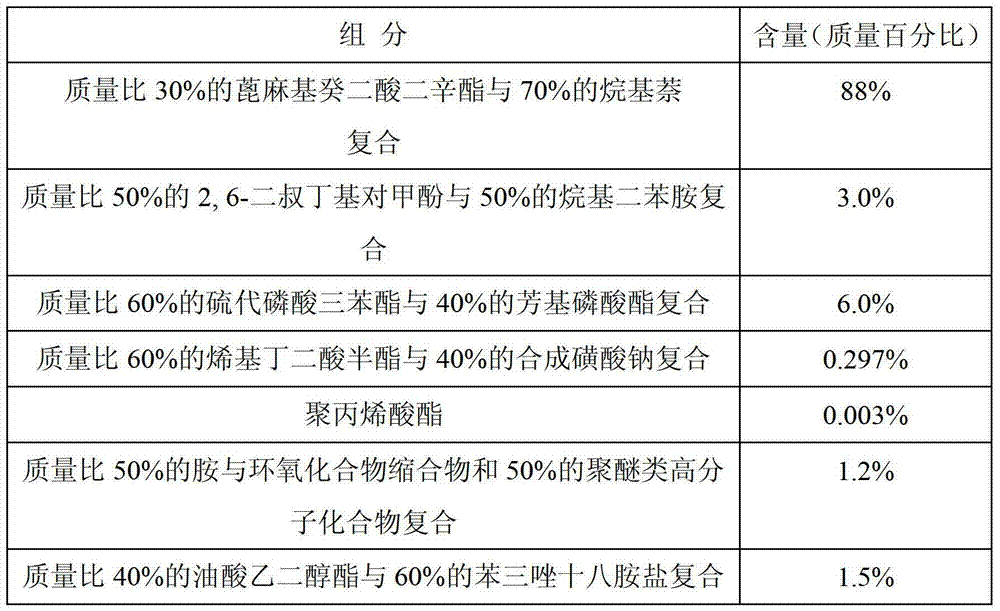

Embodiment 1

[0020] Blend the following components by mass percentage:

[0021]

[0022] The sum of the above components is 100%.

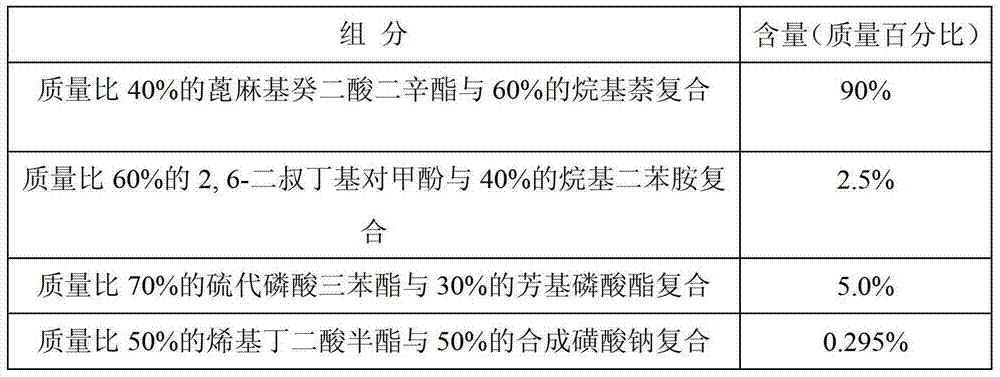

Embodiment 2

[0024] Blend the following components by mass percentage:

[0025]

[0026]

[0027] The sum of the above components is 100%.

Embodiment 3

[0029] Blend the following components by mass percentage:

[0030]

[0031] The sum of the above components is 100%.

[0032] Through the comprehensive evaluation of lubricating oil, all the physical and chemical indexes of the oil product of the present invention meet the requirements for use. Table 1 shows the typical physical and chemical indexes of the oil developed in Example 1.

[0033] Table 1 Typical physical and chemical indicators of hydraulic operating oil for construction machinery

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com