Combination circulation steam turbine lubricating oil composition

A lubricating oil composition and combined cycle technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of pump cavitation, equipment damage, control valve lockup, etc., and achieve excellent high temperature oxidation resistance, Excellent extreme pressure performance, the effect of meeting lubrication requirements

Active Publication Date: 2010-07-28

PETROCHINA CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The oil sludge produced by oxidation has many hazards to the normal operation of the steam turbine unit. For example, the oil sludge blocks the filter screen of the pump suction port, causing cavitation in the pump; the oil sludge sticks to the control valve, causing control deviation, and in severe cases, it will cause the control valve to lock. ;Oil sludge can also be deposited on the bearing surface to increase its temperature and cause equipment damage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

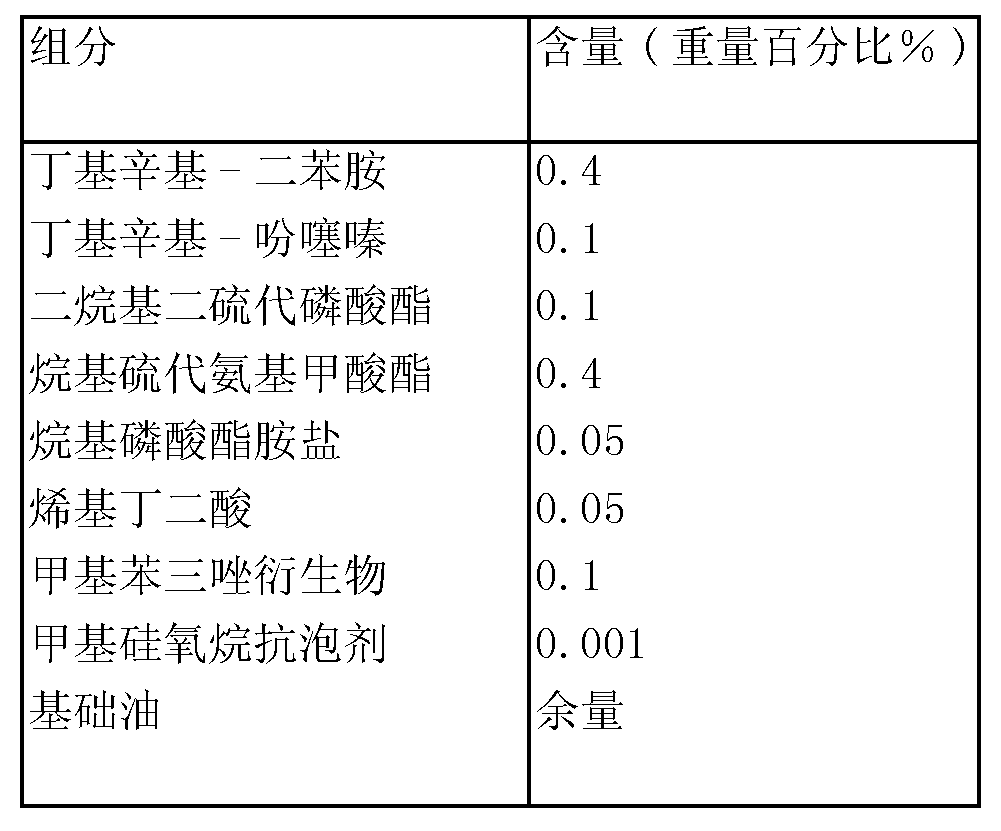

[0019] components

Embodiment 3

[0024] components

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a combined-cycle gas turbine lubricant combination which is suitable to be used in a large-scale gas steam combined-cycle gas turbine, and the composition and content of the combined-cycle gas turbine lubricant combination by weight percentage of antioxidant of 0.1 to 2 percent, anti-wear agent of 0.01 to 1 percent, no gray rust-proof agent of 0.01 to 1 percent, metal deactivating agent of 0.01 to 1 percent, anti-foam agent of 0.001 to 1 percent, the allowance is based oil, which is Class II or Class III paraffin-based oil, and the sulfur content is less than 0.03 percent, the lubricant combination of the invention has an extremely long induction period of oxidation and excellent performance of high temperature oxidation, excellent extreme pressure antifriction property and corrosion, good water separation, air separation and filterability, and can well meet the lubricating demand of large-scale combined cycle gas turbine.

Description

technical field [0001] The invention relates to a combined cycle steam turbine lubricating oil composition suitable for a large gas-steam combined cycle steam turbine unit. Background technique [0002] The steam turbine oil used in the gas-steam combined cycle system needs to meet the lubrication requirements of both the gas turbine and the steam turbine, so higher requirements are placed on the performance of the steam turbine oil. First of all, the lubricating oil used in the combined cycle unit needs to have excellent high temperature oxidation and corrosion resistance. Since the initial gas temperature of the gas turbine is above 1200°C, the temperature of its bearings can reach 120°C. High temperature conditions directly affect the oxidation rate of oil products. At the same time, the output power of the steam turbine / the volume of the oil tank is constantly increasing, that is, the circulation coefficient of the steam turbine oil is constantly increasing, all of which...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M137/10C10N30/14C10N30/10C10M133/44C10N30/12C10N40/14C10N30/06C10M135/36C10N30/18C10M145/00

Inventor 王辉吴祖望孙东金琴华

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com