Converter smelting control device and control method based on reference heat grouping

A control method and converter smelting technology, applied in the field of converter smelting, can solve the problems such as the inability to greatly improve the end point hit rate, the inability to meet the grouping method, and the inability to adapt to changes, so as to improve the end point hit rate, improve the level of intelligence, The effect of finish hit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

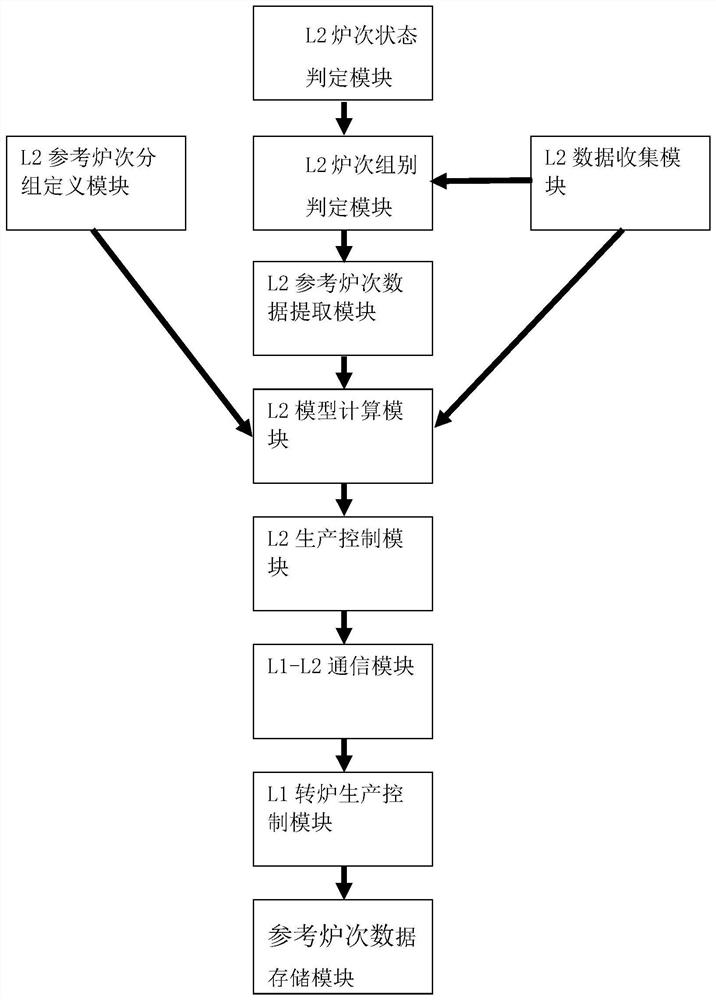

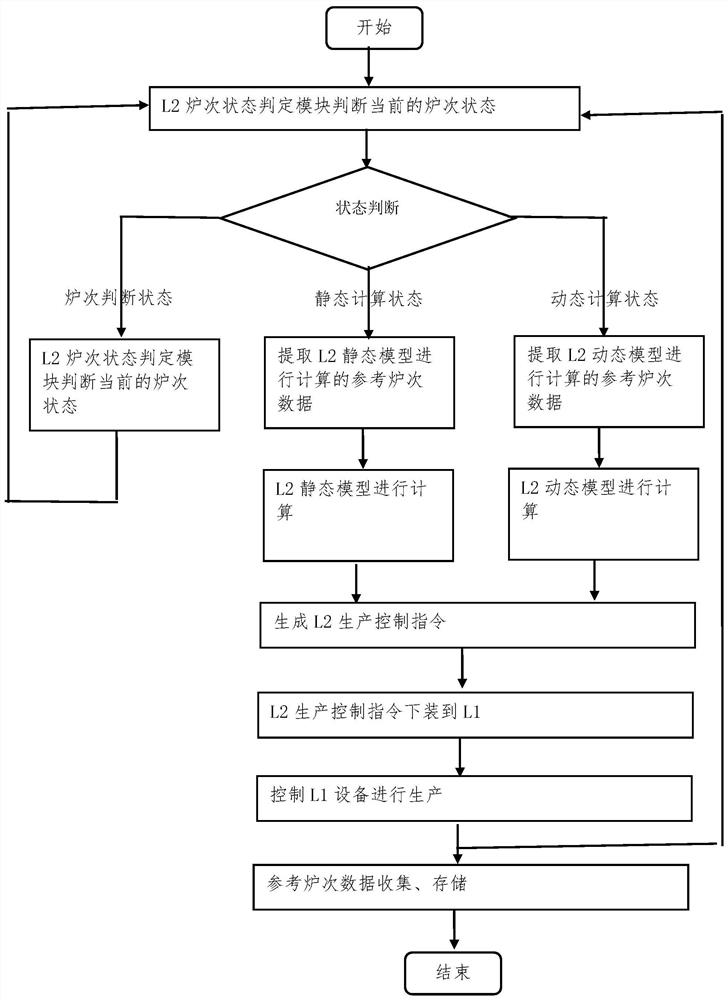

Embodiment 1

[0072] Take converter 5071212 as an example.

[0073] (1) The L2 reference heat group definition storage module defines reference heat group standards and stores them in the L2 database correlation table.

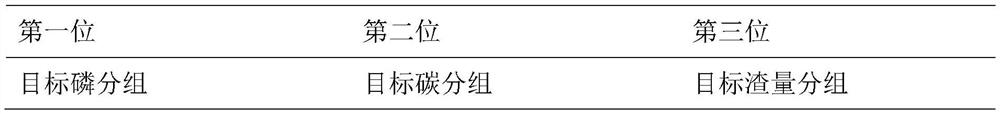

[0074] ① Definition of grouping rules

[0075] L2 refers to the grouping of furnaces, and according to the target composition of phosphorus, target carbon, and target slag, it is divided into three definitions. The definition mode is as follows:

[0076]

[0077] ②Group parameter definition data storage

[0078] Create a table in the L2 database, store the relevant parameters of the group, and provide corresponding maintenance changes, and the process engineer can perform maintenance according to the process requirements. As shown in the table below.

[0079]

[0080] ③If the furnace status meets the conditions for furnace group judgment, the furnace group judgment will be carried out.

[0081] The target components are grouped mainly according to the target phosp...

Embodiment 2

[0113] Take converter 4072412 as an example.

[0114] (1) The L2 reference heat group definition storage module defines reference heat group standards and stores them in the L2 database correlation table.

[0115] ① Definition of grouping rules

[0116] L2 refers to the grouping of furnaces, and according to the target composition of phosphorus, target carbon, and target slag, it is divided into three definitions. The definition mode is as follows:

[0117]

[0118] ②Group parameter definition data storage

[0119] Create a table in the L2 database, store the relevant parameters of the group, and provide corresponding maintenance changes, and the process engineer can perform maintenance according to the process requirements. As shown in the table below.

[0120]

[0121] ③If the furnace status meets the conditions for furnace group judgment, the furnace group judgment will be carried out.

[0122] The target components are grouped mainly according to the target phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com