Assembly type energy dissipating joint connecting suspension steel columns and installation method thereof

A prefabricated, node-based technology, applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve the problems of sub-floor safety performance impact, failure, and lower sub-floor seismic performance, so as to improve energy consumption capacity and Self-resetting ability, improved force transmission, and convenient construction and installation of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

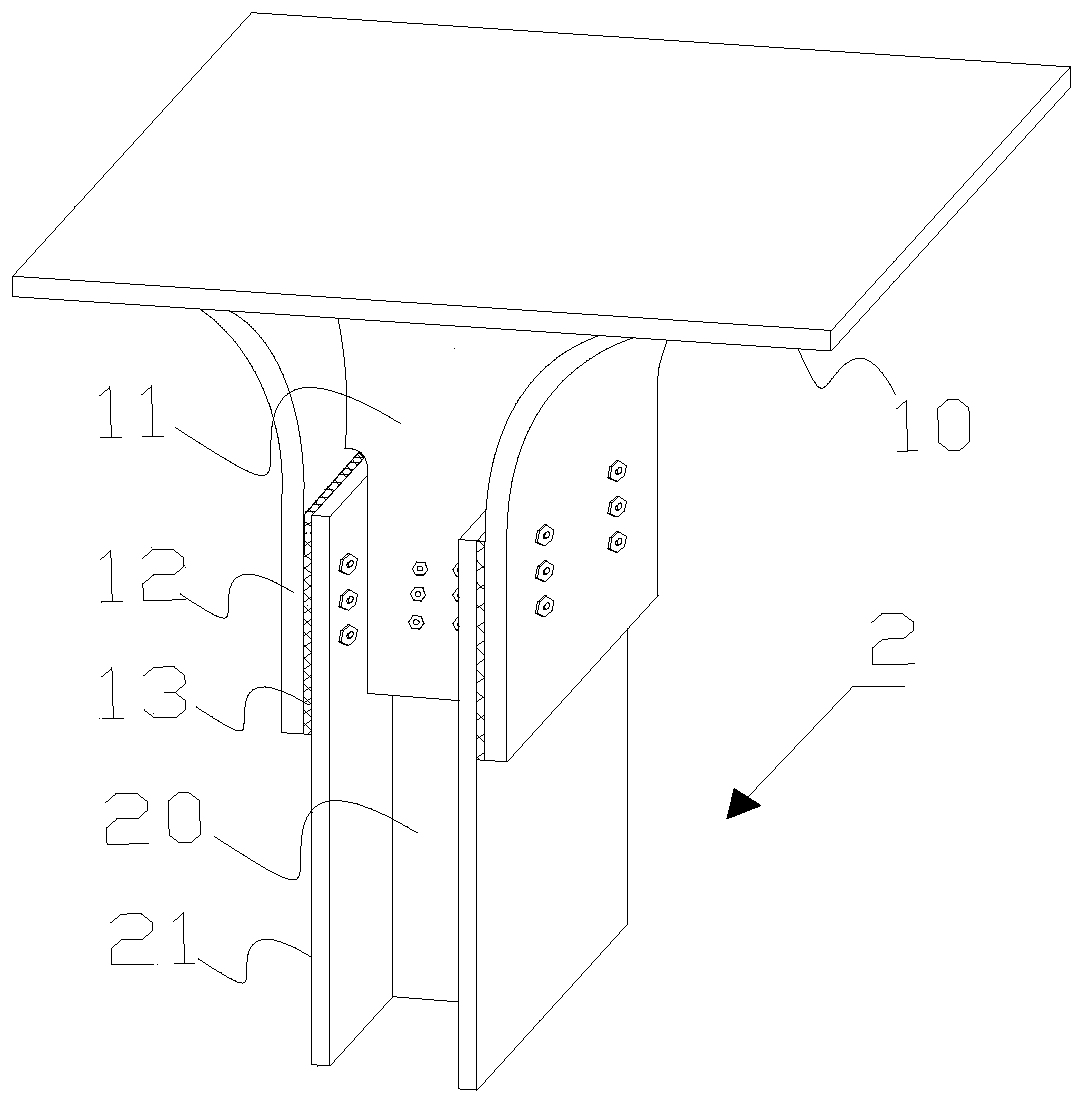

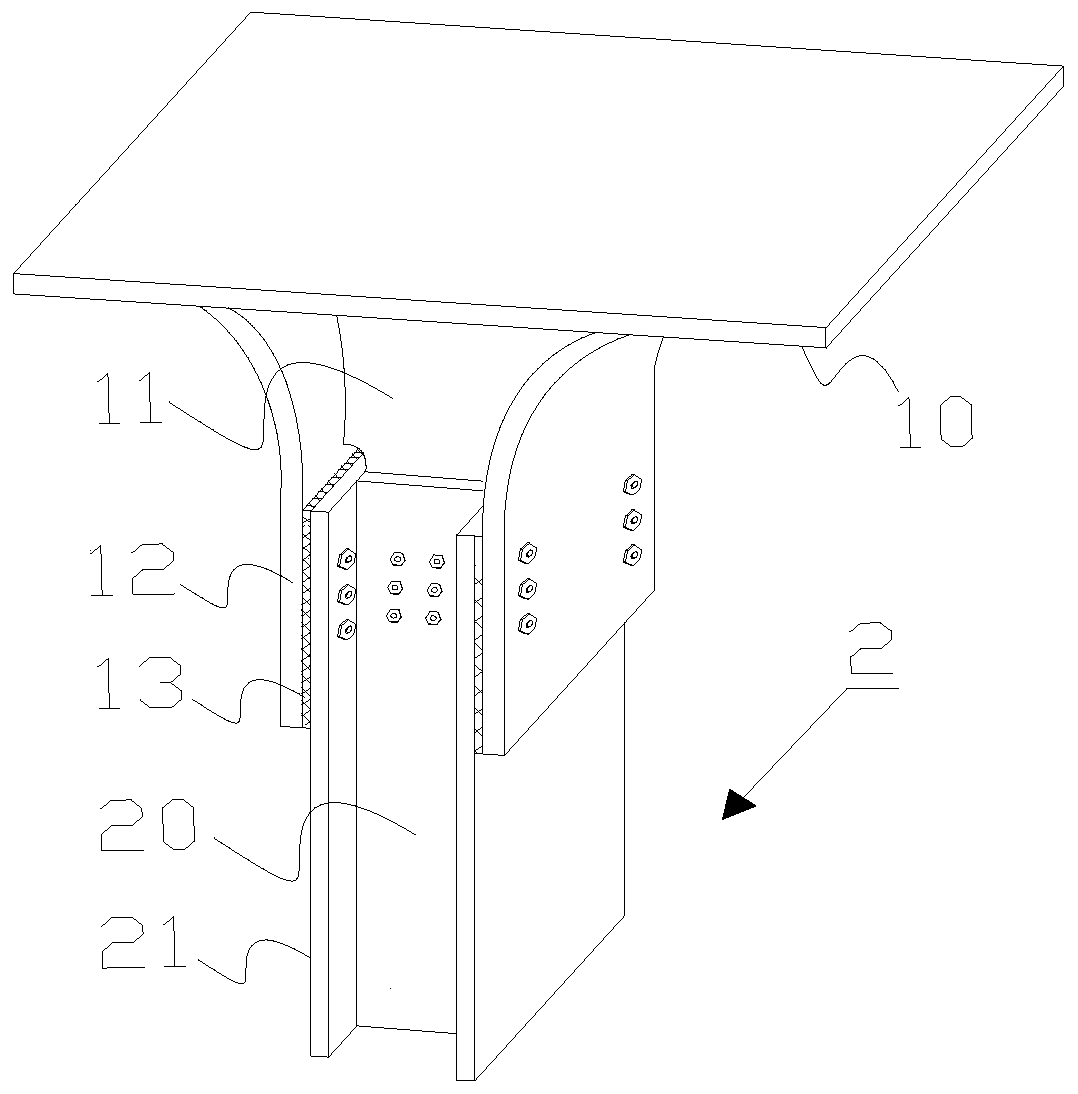

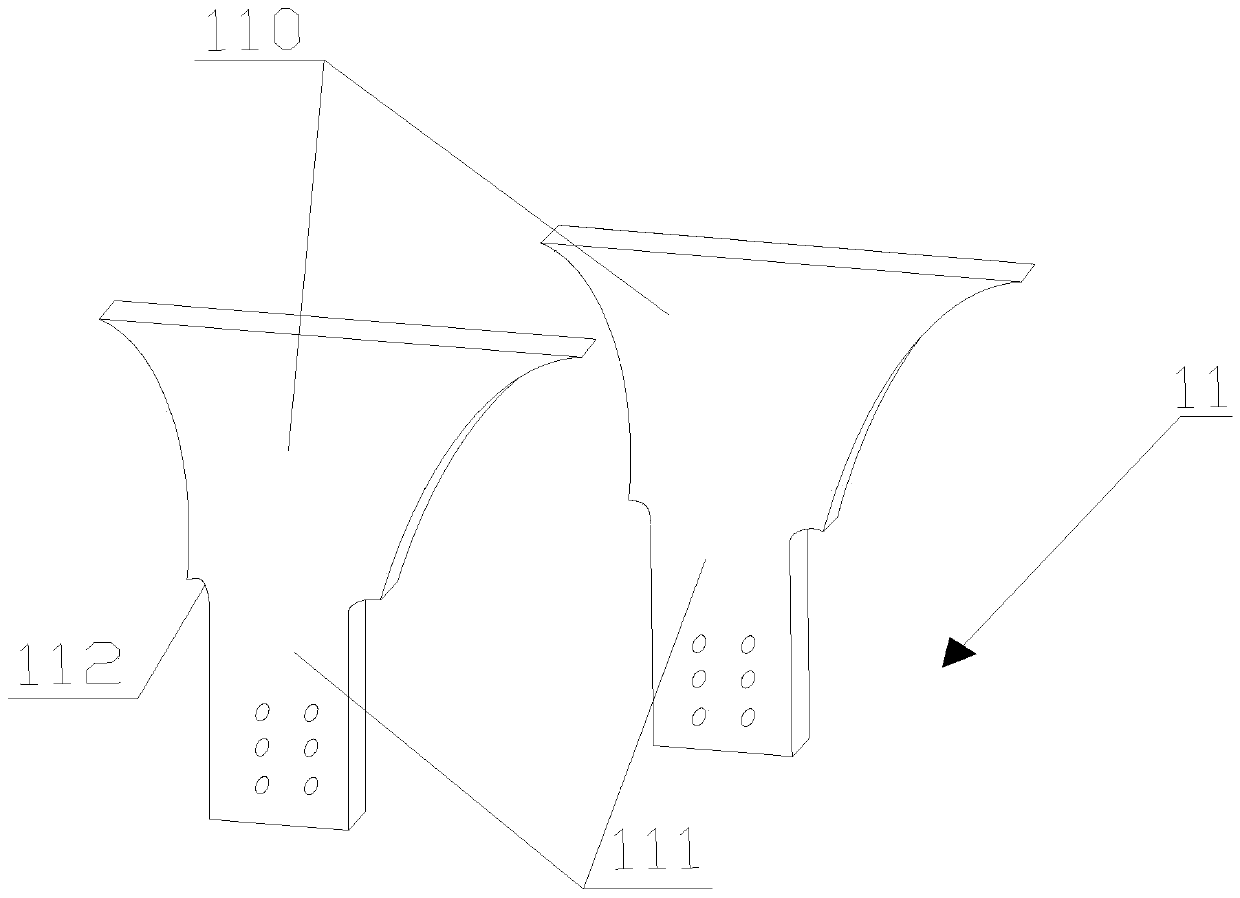

[0043] A fabricated energy-dissipating node connected to suspended steel columns, such as figure 1 and figure 2 The energy dissipation node includes an end plate 10, two energy dissipation node webs 11 arranged front and back, and two energy dissipation node flanges 12 arranged left and right, as image 3 As shown, each energy-dissipating node web 11 includes a web arc section 110 and a web straight section 111, as shown in Figure 4 As shown, each energy dissipation node flange 12 includes a flange arc segment 120 and a flange straight segment 121 . The end plate 10 is welded to the top of the web arc section 110 and the top of the flange arc section 120, and the flange is the wing plate. The energy dissipation node flanges 12 are arranged opposite to each other, the energy dissipation node webs 11 are arranged opposite to each other, and the energy dissipation node webs 11 are located between the opposite energy dissipation node flanges 12 .

[0044] Both the flange arc ...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 8 As shown, the main structure of the entire floor is a giant frame, and the giant frame includes a frame column 5 and a horizontal member 3 fixed on the top of the frame column 5. A number of energy-dissipating nodes are suspended on the horizontal member 3, which bears the main gravity of the floor 4. Installing the energy-consuming node of the present invention on the megaframe comprises the following steps:

[0051] S1, two energy dissipation node webs 11 are welded opposite to each other on the end plate 10, and the two energy dissipation node webs 11 are parallel; the flange arc section 120 of the energy dissipation node flange 12 is attached to the web On the arc section 110, the flange 12 of the energy-dissipating node is welded to the end plate 10, and the prefabrication of the energy-dissipating node is completed at this time;

[0052] S2, fixing the elastic member 13 on the flange straight section 121;

[0053] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com