Reaming bonded reinforced casing type FRP structure beam-column node

A technology of beam-column joints and sleeves, applied in the direction of building components, building types, building structures, etc., can solve the problems of insufficient ductility and easy brittle failure, and achieve the effect of improving ductility, avoiding brittle failure, and slim shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

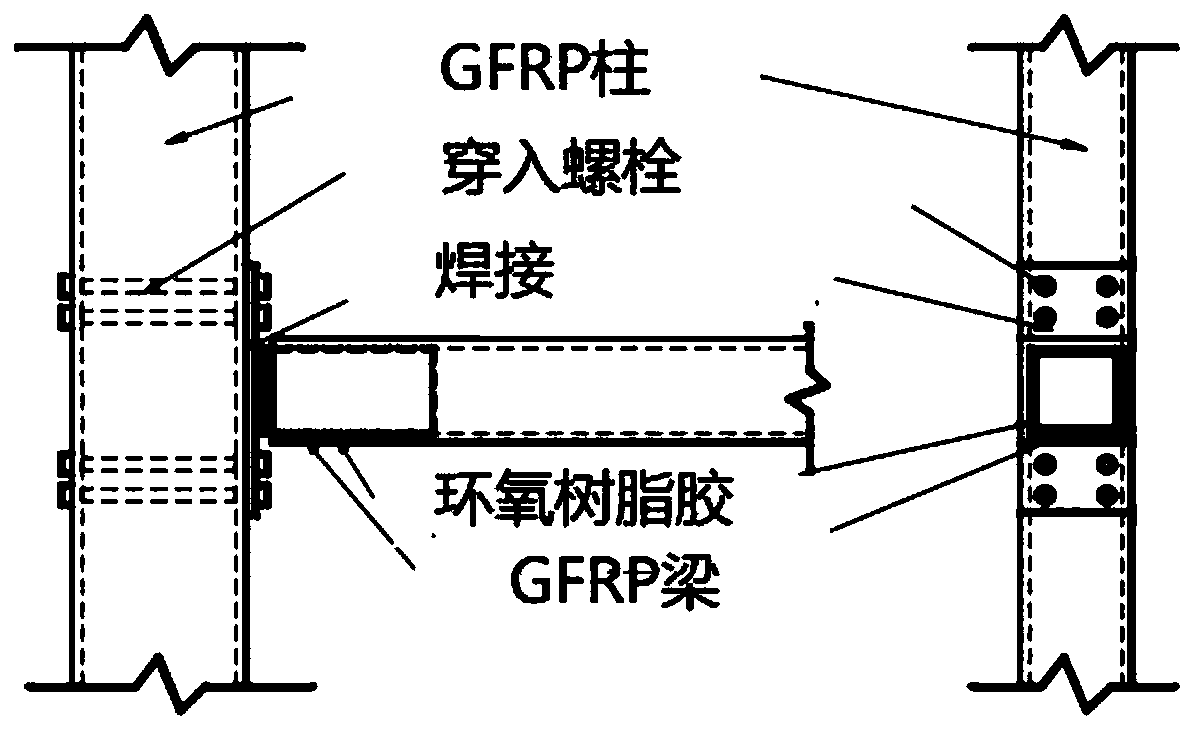

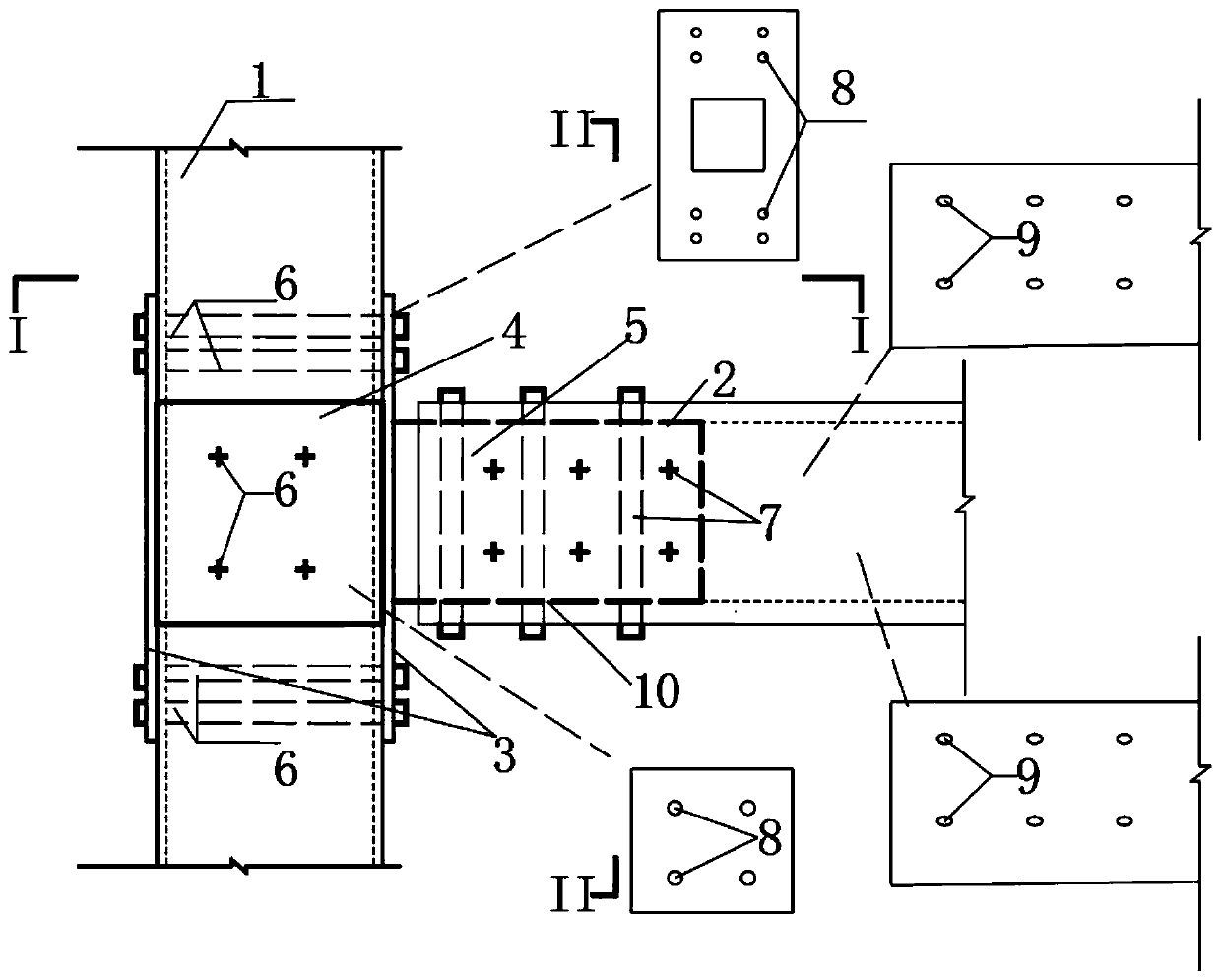

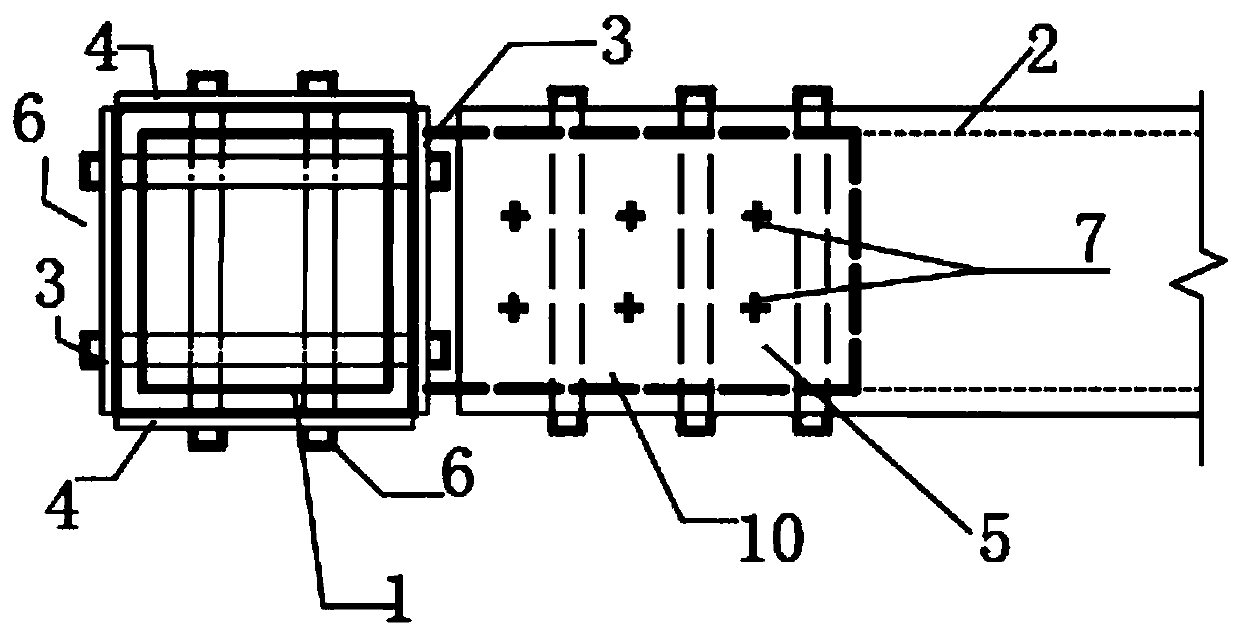

[0040] See Figure 2-6 , A reamed and glued reinforced casing FRP structural beam-column node, including FRP column 1, FRP beam 2, end plate 3, side plate 4, casing 5, high-strength penetration bolt 6, high-strength friction bolt 7, Ordinary bolt hole 8, oblong bolt hole 9 and epoxy resin 10, FRP column 1 is a square hollow FRP column, FRP beam 2 is a square hollow FRP beam, end plate 3 is provided with a pair, and a pair of end plates 3 are respectively Connected to the left and right sides of the FRP column 1, the left and right sides of the FRP column 1 and a pair of end plates 3 are provided with four pairs of ordinary bolt holes 8, six pairs of high-strength penetration bolts 6, and four pairs of high-strength penetration The bolts 6 are respectively threadedly connected between the four pairs of ordinary bolt holes 8. A pair of end plates 3 are connected to the FRP column 1 by multiple pairs of high-strength penetration bolts 6 and the connection is firm. The side plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com