Steel bridge deck slab corrosion fatigue coupling test method and device for same

A steel bridge deck, corrosion fatigue technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, and optical devices to transmit sensing components, etc. Effective and reliable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] With reference to accompanying drawing, the test method of steel bridge deck corrosion fatigue coupling test device of the present invention may further comprise the steps:

[0034] 1) Install the fabricated segmental orthotropic steel bridge deck full-scale model in the laboratory, arrange fiber grating sensors, and paste filter paper: the steel bridge deck is manufactured and processed in the factory and transported back to the fatigue laboratory for installation. Orthotropic steel bridge decks fixed in the fatigue laboratory. After the installation is completed, fiber grating strain sensors are arranged at equal intervals of 2mm within 30cm of the weld to monitor the corrosion near the weld of the steel bridge deck; secondly, the stress monitoring position is determined according to the hot spot extrapolation method and the fiber grating strain sensors are arranged And the fiber grating temperature sensor, in order to prevent the sensor from being corroded, apply epo...

Embodiment 2

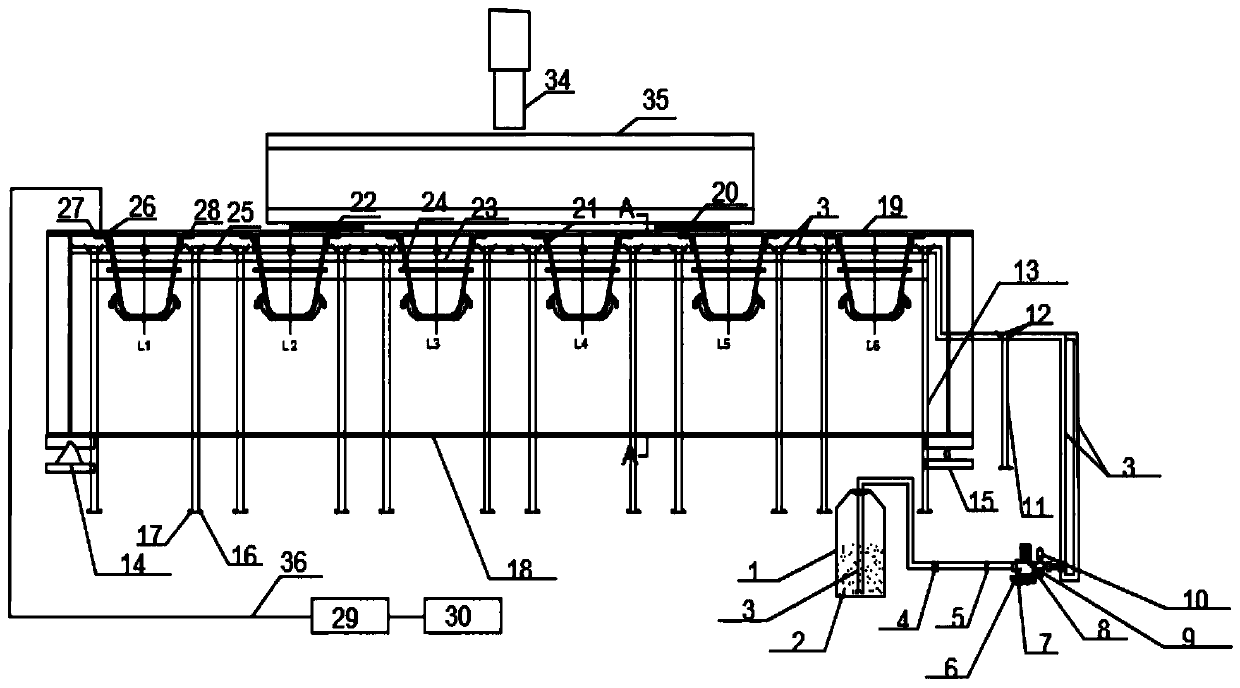

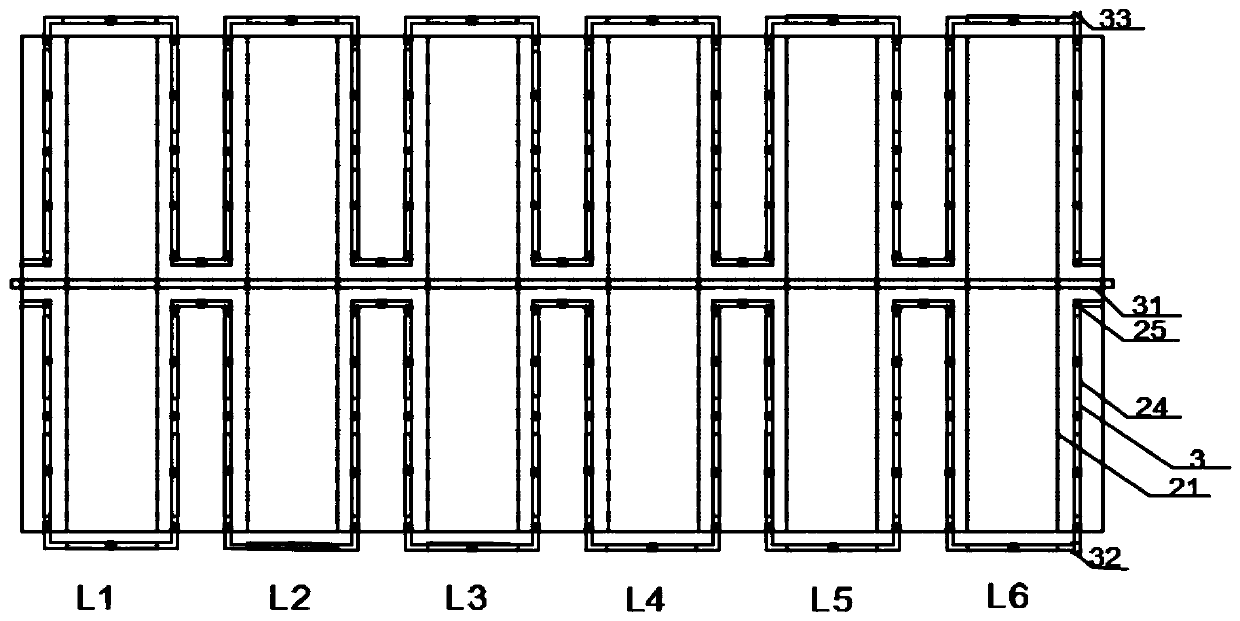

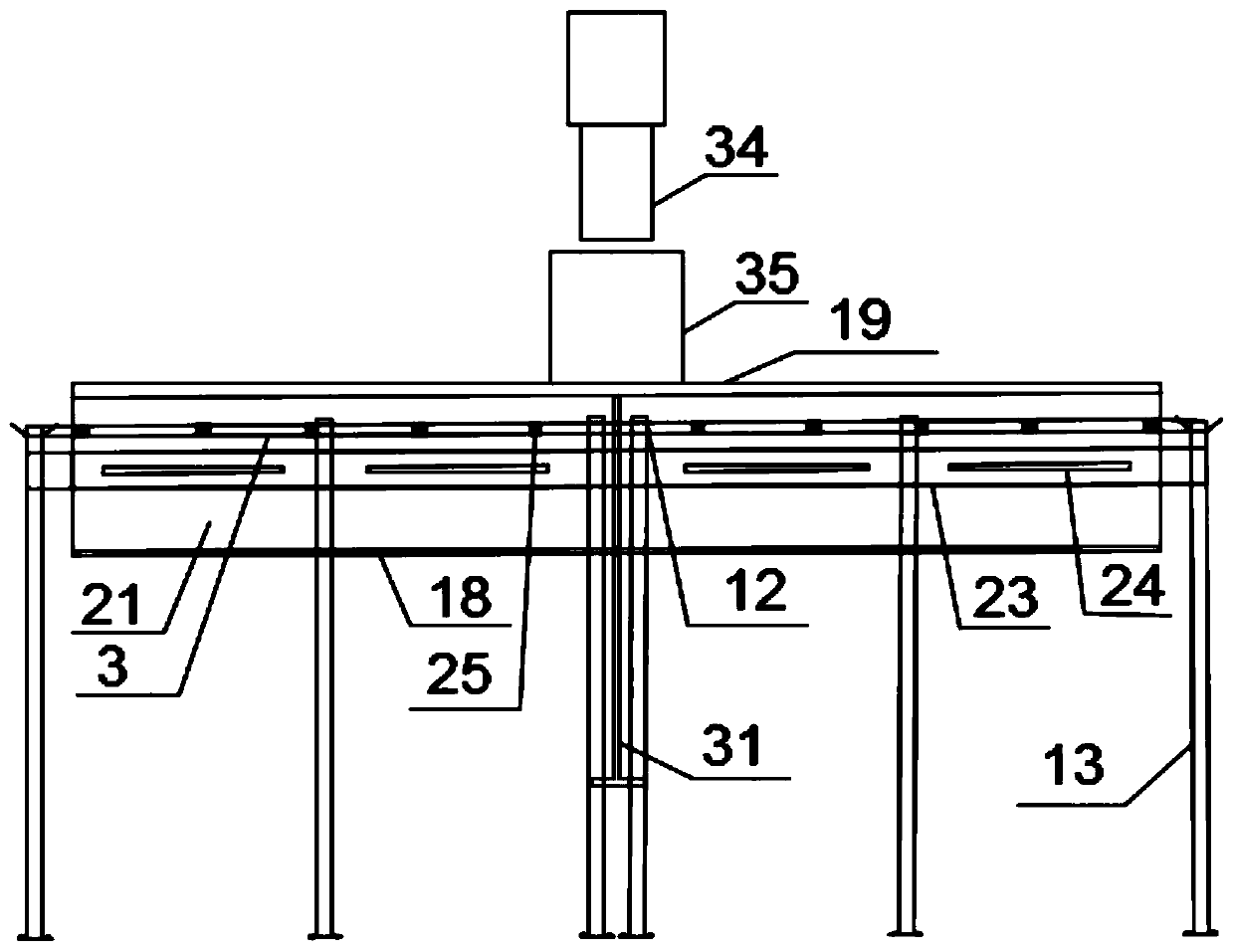

[0040] With reference to accompanying drawing, realize the device of the test method described in embodiment 1, comprise hydraulic jack 34, test loading beam 35, rubber support 20, transmission pipeline support 13, pipeline 3, infrared lamp tube 24, water tank 1, booster pump 6. It is characterized in that: the hydraulic jack 34 acts on the test loading beam 35, and a single rubber support 20 with an area of 200mm×300mm is placed between the test loading beam 35 and the test model to simulate a single tire passing through the pavement Wheel load; the transmission pipeline support 13 is fixed on the ground parallel to the bridge deck model weld seam by connecting bolts 16, the pipeline 3 equipped with the sprayer 25 is fixed on the transmission pipeline support 13 by a clamp, and the transmission pipeline support is below the pipeline 3 Binding plank 23 on 13, infrared lamp tube 24 is installed on the plank 23; Place a water tank 1 that 3.5% sodium chloride solution 2 is house...

Embodiment 3

[0053] In this example, a Q345qd steel orthotropic steel bridge deck foot of Q345qd steel with a thickness of 14 mm for the cover plate, a thickness of 12 mm for the lower wing, a thickness of 10 mm for the diaphragm, a size of U-rib of 300 mm×280 mm×8 mm, and a center distance of U-rib of 600 mm is selected. The scale model is used as the experimental object to explain the design idea of the test device and the corrosion fatigue coupling scheme.

[0054] 1. Design and implementation of corrosion fatigue test device:

[0055] ⑴Design and production of spray system

[0056] The spray system mainly includes a water tank, a booster pump, a ppr water pipe with a diameter of 20mm, an ordinary fire pipe with a diameter of 25mm for supporting the ppr pipe, and an intelligent control system (for controlling the time of spraying). After the position of the orthotropic steel bridge deck is determined, the water pipe support pipe is installed, and the position of the support pipe is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com