Method for manufacturing shunt resistor

A technology of shunt resistance and manufacturing method, applied in resistance manufacturing, resistors, resistor parts and other directions, can solve the problems of poor appearance of weld bead, change of resistance composite material, material splash and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

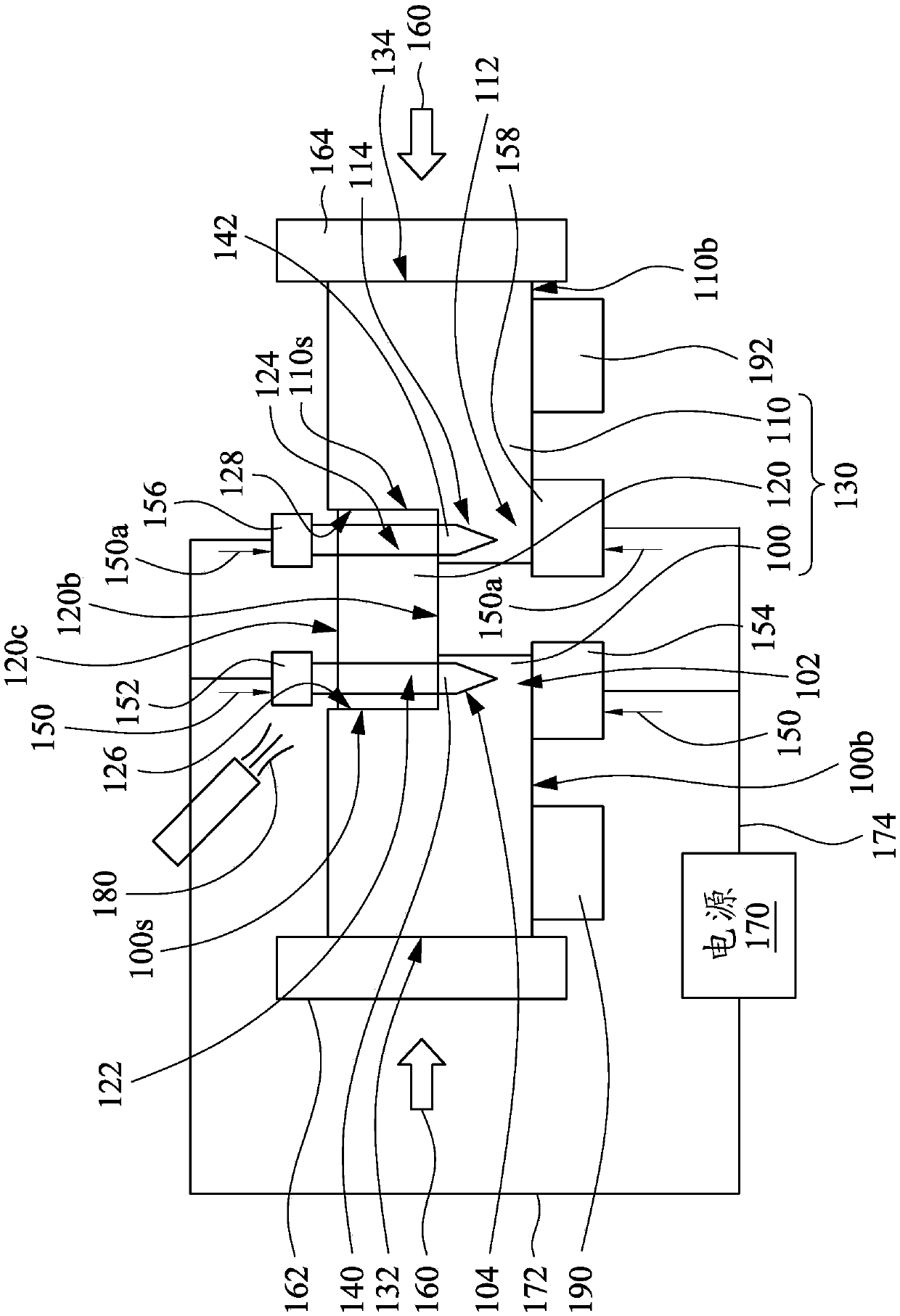

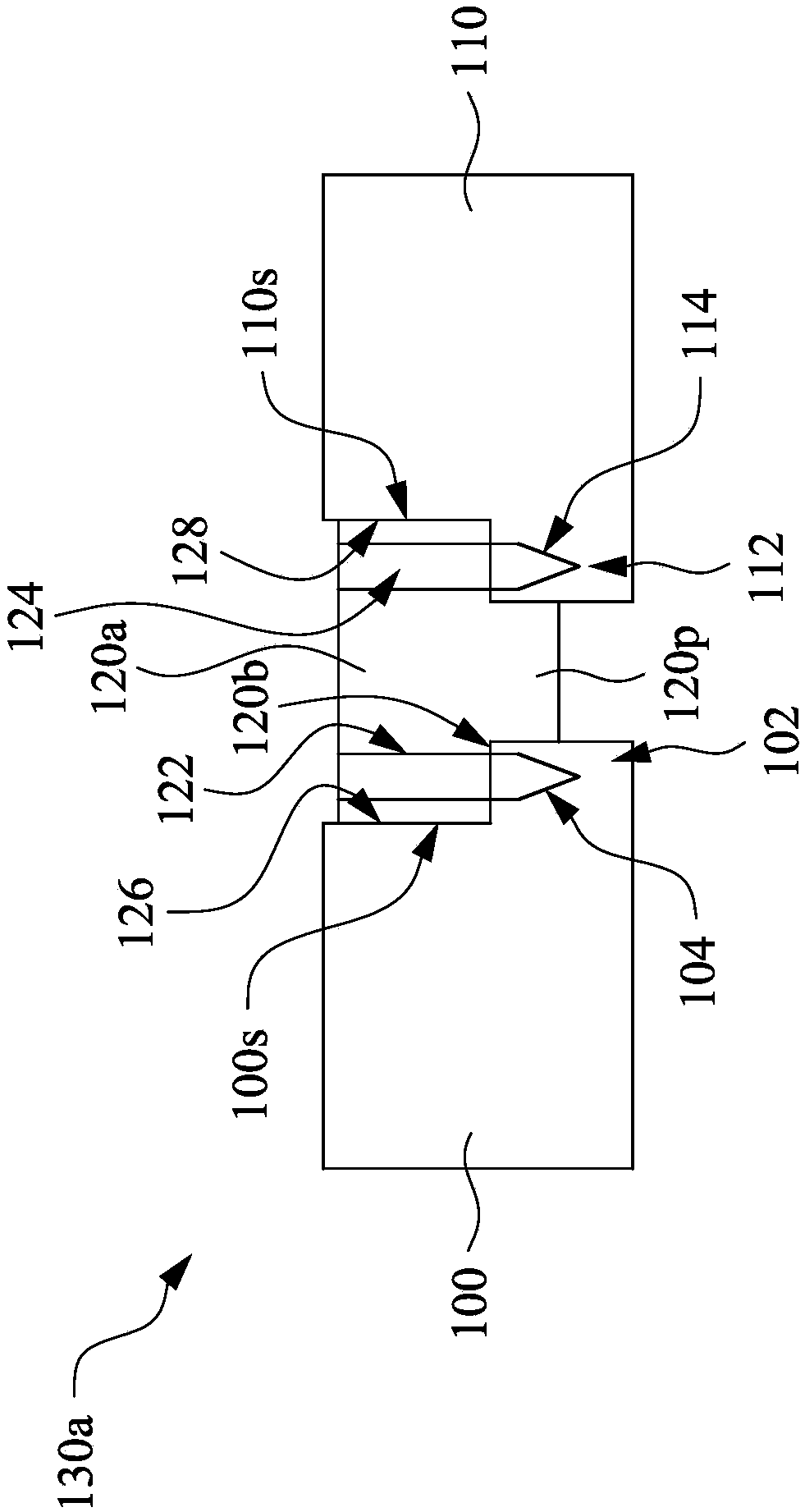

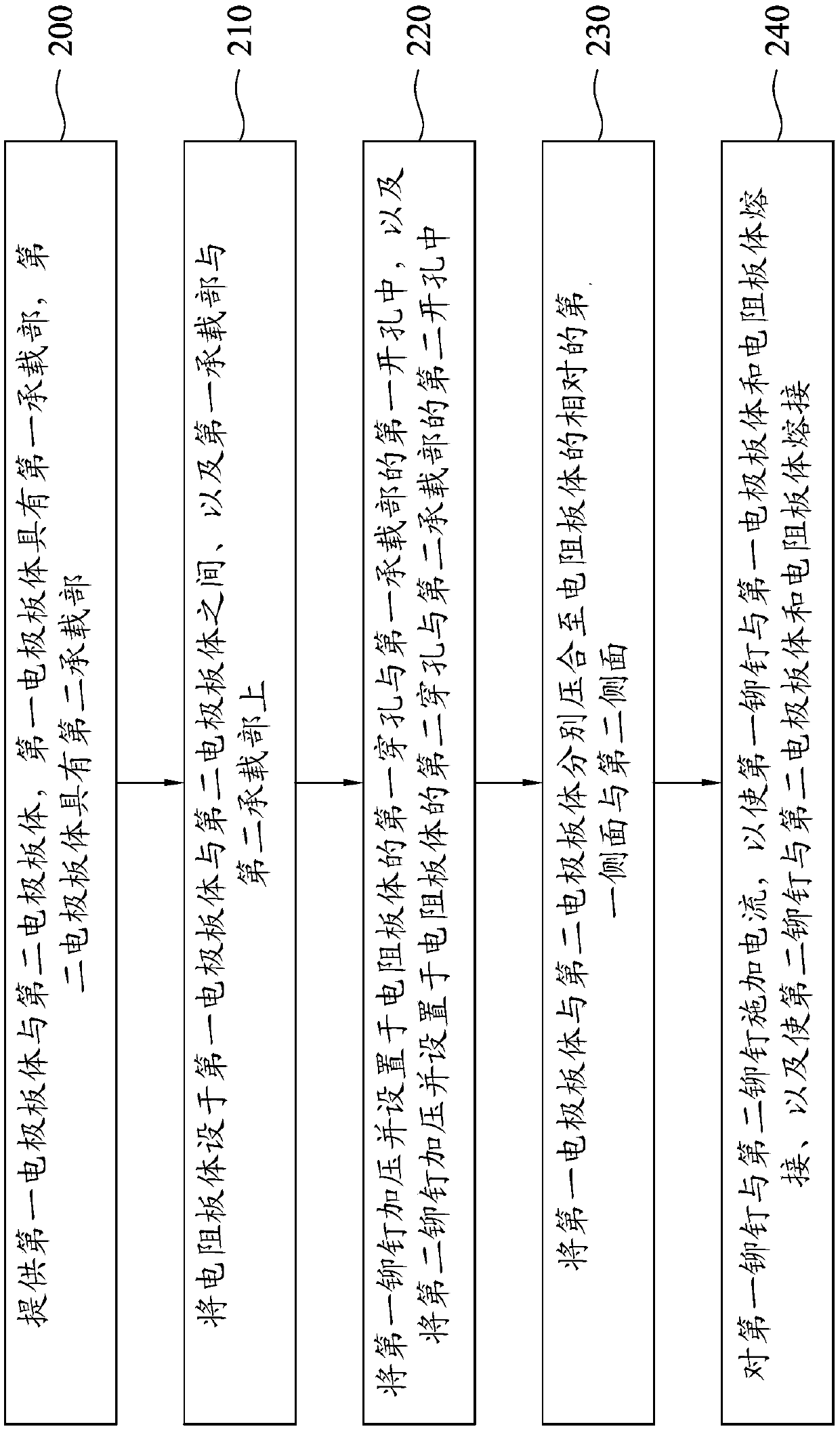

[0025] Please also refer to Figure 1A and figure 2 , which are respectively a schematic diagram and a flowchart of an apparatus for manufacturing a shunt resistor according to the first embodiment of the present invention. In this embodiment, when manufacturing the shunt resistor, step 200 is first performed to provide the first electrode plate body 100 and the second electrode plate body 110 . The first electrode plate body 100 includes a first bearing portion 102 , wherein the first bearing portion 102 protrudes from a side surface 100s of the first electrode plate body 100 . The second electrode plate body 110 includes a second bearing portion 112 , wherein the second bearing portion 112 protrudes from a side surface 110s of the second electrode plate body 110 . In other embodiments, the first electrode plate body 100 and the second electrode plate body 110 may include a stepped structure. The first electrode plate body 100 has at least one first opening 104 , wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com