Preparation method of anode material, anode material and lithium battery

A technology of negative electrode material and polar solvent, applied in the field of preparation of negative electrode material, can solve the problems of poor solvent compatibility, poor charging and discharging performance at high current, and poor modification effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of negative electrode materials

[0051] 1) Add 4g of polyacrylonitrile powder to 196g of dimethylformamide, and magnetically stir and dissolve to obtain a polyacrylonitrile solution with a mass concentration of 2%, wherein the number average molecular weight of polyacrylonitrile is 130,000, and the stirring speed is 25r / min, the stirring temperature (water bath heating) was 30°C, and the stirring time was 3h.

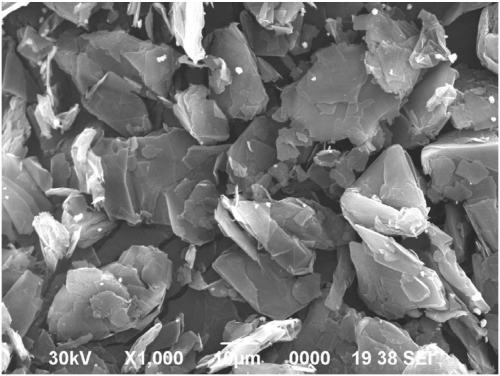

[0052] 2) Add 20 g of graphite with an average particle size of 13.00 μm into the polyacrylonitrile solution described in step 1), and stir magnetically to obtain a suspension at a stirring speed of 20 r / min, a stirring temperature of 25° C., and a stirring time of 2 h.

[0053] 3) separating the solid-liquid phase of the suspension in step 2) with a centrifuge to obtain the solid phase of the lower layer.

[0054] 4) Add the solid phase described in step 3) into 300mL coagulation bath (deionized water), the temperature of the coagulation bath is 2...

Embodiment 2

[0064] The difference between the preparation of the negative electrode material and Example 1 is that in step 1), 2 g of polyacrylonitrile powder was added to 198 g of dimethylformamide, and magnetically stirred to obtain a polyacrylonitrile solution with a mass concentration of 1%.

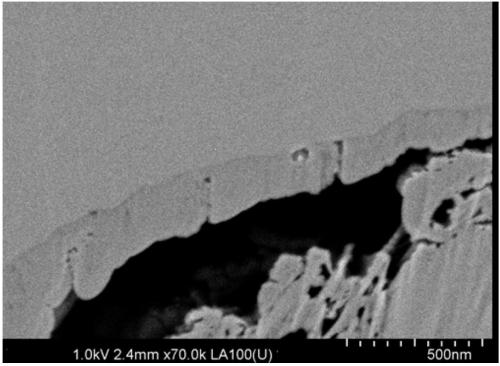

[0065] The prepared negative electrode material includes graphite and a hard carbon layer coated on the outer surface of the graphite, wherein the hard carbon layer has a thickness of 50 nm, the average particle size of the negative electrode material is 13.12 μm, and the graphite and The mass ratio of the negative electrode material is 1:1.01.

[0066] The preparation of lithium battery (button cell) is with embodiment one;

[0067] Electrical performance test

[0068] Test condition is with embodiment one;

[0069] Test results: the initial discharge capacity is 366mAh / g, and the initial efficiency can reach 92.3%.

Embodiment 3

[0071] The difference between the preparation of the negative electrode material and Example 1 is that in step 1), 20 g of polyacrylonitrile powder was dissolved in 180 g of dimethylformamide, and magnetically stirred to obtain a polyacrylonitrile solution with a mass concentration of 10%.

[0072]The prepared negative electrode material includes graphite and a hard carbon layer coated on the outer surface of the graphite, wherein the hard carbon layer has a thickness of 800 nm, the average particle size of the negative electrode material is 14.80 μm, and the graphite and The mass ratio of the negative electrode material is 1:1.13.

[0073] The preparation of lithium battery (button cell) is with embodiment one;

[0074] Electrical performance test

[0075] Test condition is with embodiment one;

[0076] Test results: the initial discharge capacity is 369mAh / g, and the initial efficiency can reach 92.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com