Electro-optic Q-switched laser

A laser and electro-optical technology, applied in the field of lasers, can solve the problems of difficult crystal growth, etc., and achieve the effect of compact structure, high switching ratio and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

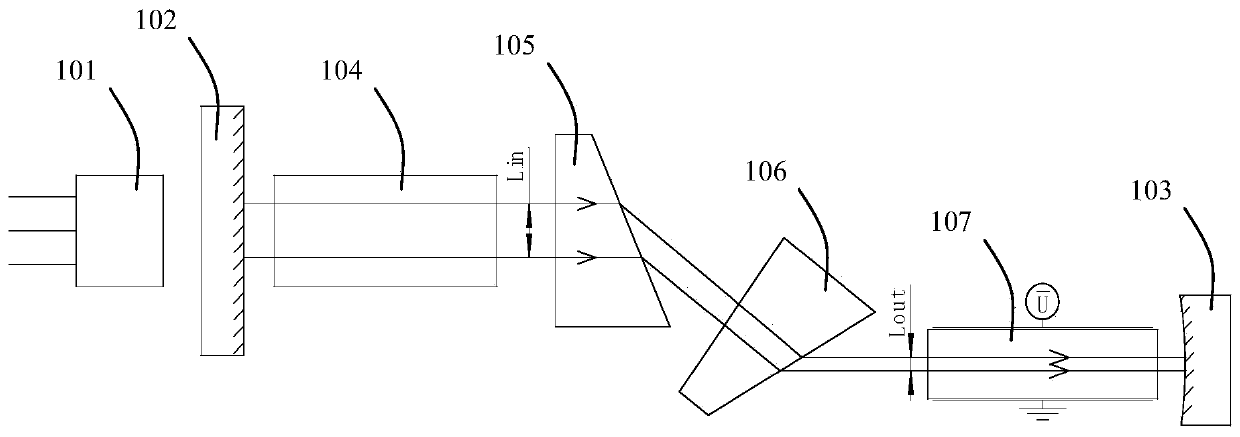

Embodiment 1

[0020] see figure 1 , this implementation case provides an electro-optic Q-switched laser, including a pumping laser system 101, the pumping laser system 101 is provided with a coaxial planar lens 102 and a gain medium 104 in turn behind the pumping focused beam, and through the gain The medium 104 sequentially compresses the lateral spot of the laser cavity mode through the first spot compression prism 105 and the second spot compression prism 106, and then passes through the BBO electro-optic crystal Q-switching switch unit 107, behind which the BBO electro-optic crystal Q-switching switch unit 107 A plano-concave output mirror 103 is provided to output Q-switched pulse laser, and the plane mirror 102 and the plano-concave output mirror 103 constitute a laser resonant cavity.

[0021] This embodiment takes Nd:YVO4 crystal as the gain medium 104 as an example to illustrate its working principle. First, the pumping laser system 101 outputs a pumping focused beam with a wavelen...

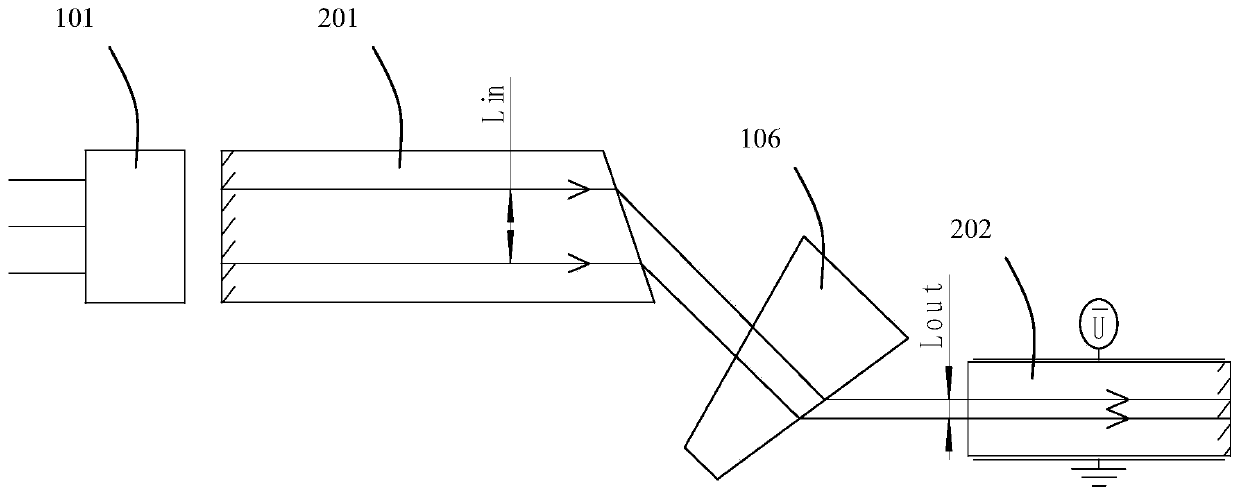

Embodiment 2

[0024] see figure 2 , the principle of obtaining electro-optic Q-switched pulsed laser and figure 1 In the same way, only the flat lens 102 and the gain medium 104 are replaced by a laser crystal 201, wherein the front surface of the laser crystal 201 is coated with HR@1064nm and AR@808nm, and the rear end surface of the laser crystal 201 is polished into a cloth angle surface to compress the light spot, BBO The rear surface of the electro-optic crystal 202 is coated with PR@1064nm. This structure is more compact and convenient for laser adjustment.

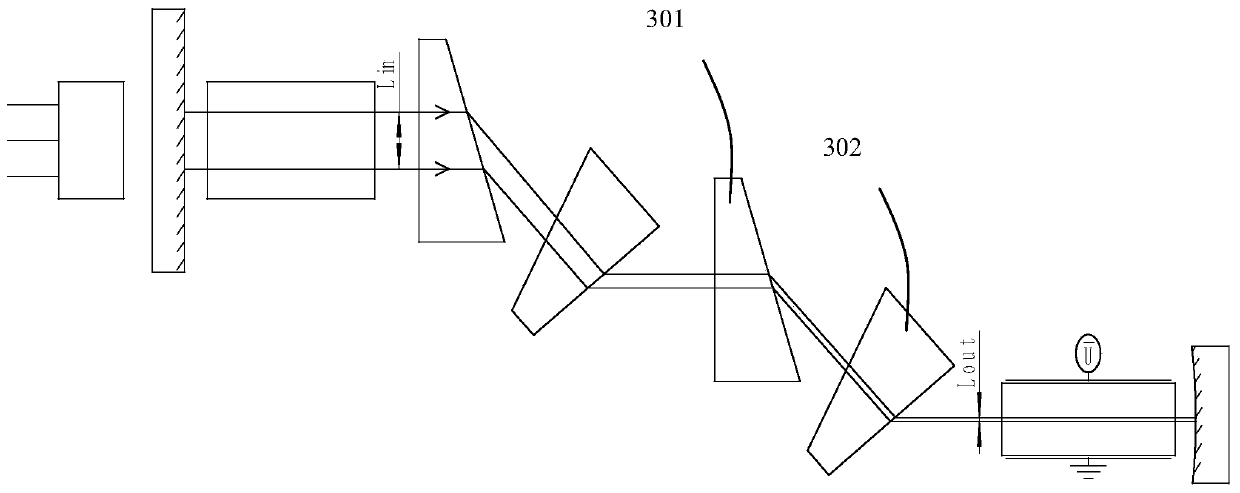

Embodiment 3

[0026] see image 3 In this embodiment, the third spot compression prism 301 and the fourth spot compression prism 302 are cascaded after the first spot compression prism 105 and the second spot compression prism 106, which can further compress the laser spot and further reduce the thickness of the electro-optic crystal electrode. In order to obtain a lower 1 / 4 wave voltage. The Q-switching principle and implementation process are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com