Preparation method of hip joint bone cement interposition and special bending machine thereof

A technology for bone cement and hip joint, applied in the medical field, can solve problems such as difficulty in walking, poor postoperative function, and difficulty in accurately controlling length and angle, and achieve the effects of convenient accuracy, good practicability, and improved surgical efficiency and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

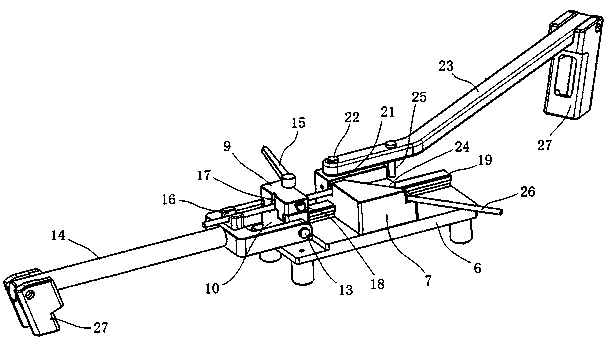

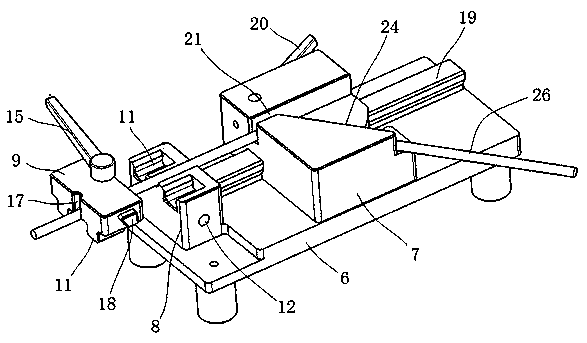

[0033] This example proposes a preparation method of a bone cement interposition of the hip joint and its special bending machine. The preparation method of the bone cement interposition of the hip joint has the advantages of high shape precision of the interposition, convenient preparation, and no metal exposure , can effectively improve the preparation efficiency and improve the operation effect. The bending machine has the advantages of convenient use and high precision.

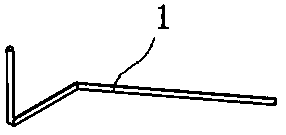

[0034]The preparation method of the hip joint bone cement interposition of the present invention is as follows: first cast the interposition femoral stem 2 with the metal bracket 1, and ensure that the tail end of the metal bracket 1 is embedded in the interior of the interposition femoral stem 2; The head end of the interposition femoral stem 2 is put into the femoral head casting mold 3, and finally the interposition femoral head 4 connected with the interposition femoral stem 2 is cast, and the interpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com