Efficient dust collection, desulfuration and white smoke elimination device and method

A high-efficiency, white-smoke technology, applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of low dust removal efficiency, white smoke generation, uneven mixing of exhausted flue gas, etc., and achieve the effect of improving dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

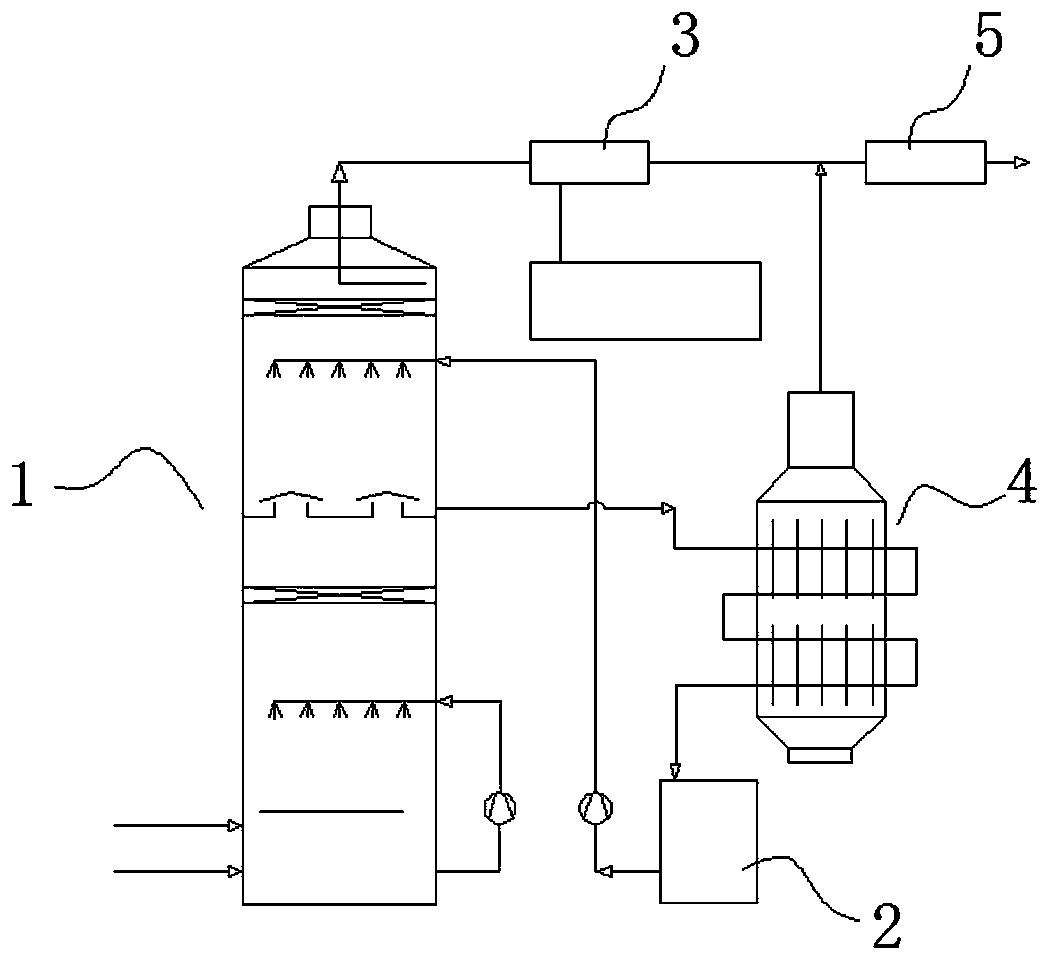

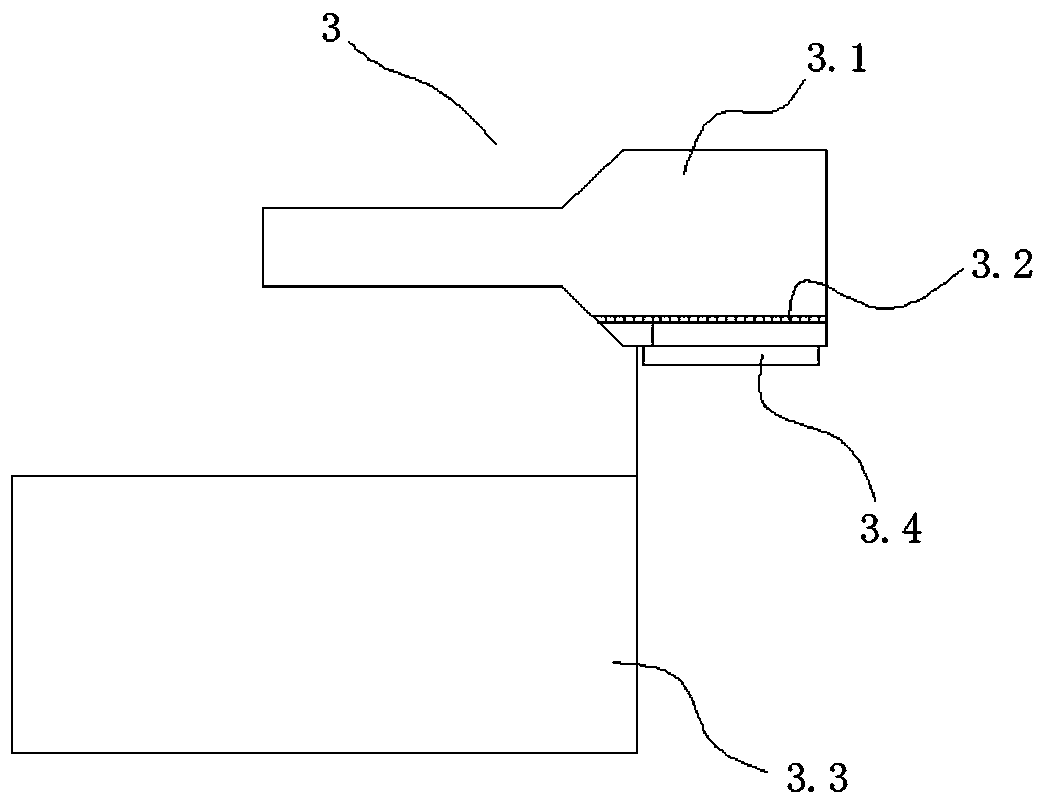

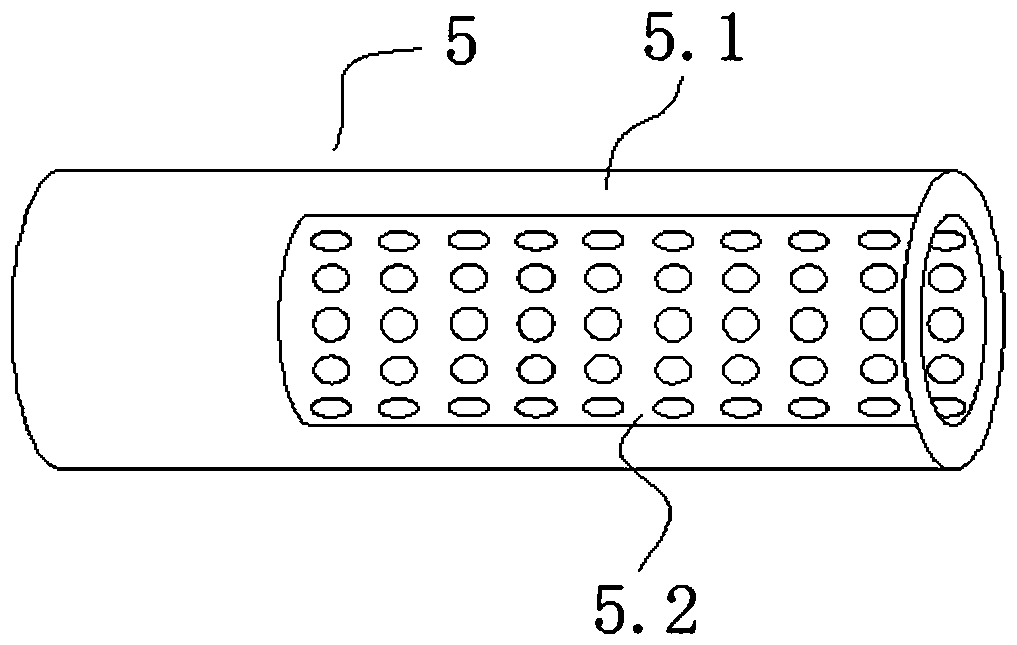

[0039] Such as Figure 1 to Figure 3 As shown, the high-efficiency dust removal, desulfurization and white smoke removal device includes a desulfurization tower 1, a circulating water tank 2 and an electrostatic precipitator 3. The circulating water tank 2 is connected to the desulfurization tower 1 through a water pipe, and the circulating water tank 2 is connected to the The desulfurization tower 1 transports water; the input end of the electrostatic precipitator 3 communicates with the output end of the desulfurization tower 1; the desulfurization tower 1 introduces the original flue gas, and desulfurizes and removes the original flue gas; the electrostatic precipitator 3 The flue gas after desulfurization and dust removal is subjected to electrostatic dust removal.

[0040] The desulfurization tower 1 is sequentially arranged with a desulfurization liquid circulation pool, a desulfurization liquid spray layer, a desulfurization demister, a hood partition, a cold water spra...

Embodiment 2

[0056] Such as Figure 1 to Figure 3 As shown, the efficient dust removal, desulfurization and white smoke removal method includes the following steps:

[0057] The circulating water tank 2 delivers water to the desulfurization tower 1; the desulfurization tower 1 introduces the original flue gas, and sprays water with the water flow to desulfurize and remove the dust from the original flue gas; the electrostatic precipitator 3 performs electrostatic dust removal on the desulfurized and dust-removed flue gas, Discharge the flue gas after electrostatic dust removal.

[0058] The desulfurization tower 1 is sequentially arranged with a desulfurization liquid circulation pool, a desulfurization liquid spray layer, a desulfurization demister, a hood partition, a cold water spray layer, and a dust and demister eliminator from bottom to top. The upper end of the desulfurization tower 1 A gas outlet communicating with the inside thereof is provided; a desulfurization circulation pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com