Rolling method capable of enhancing compositing effects of dissimilar metal composite plate

A technology of dissimilar metals and composite plates, applied in the direction of metal rolling, etc., can solve the problems of affecting the plastic deformation performance of the interface layer, affecting the bonding strength of the composite interface, etc., so as to reduce the number of composite interface compounds and defects, and enhance the interface bonding strength. , The effect of solving the rolling force problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

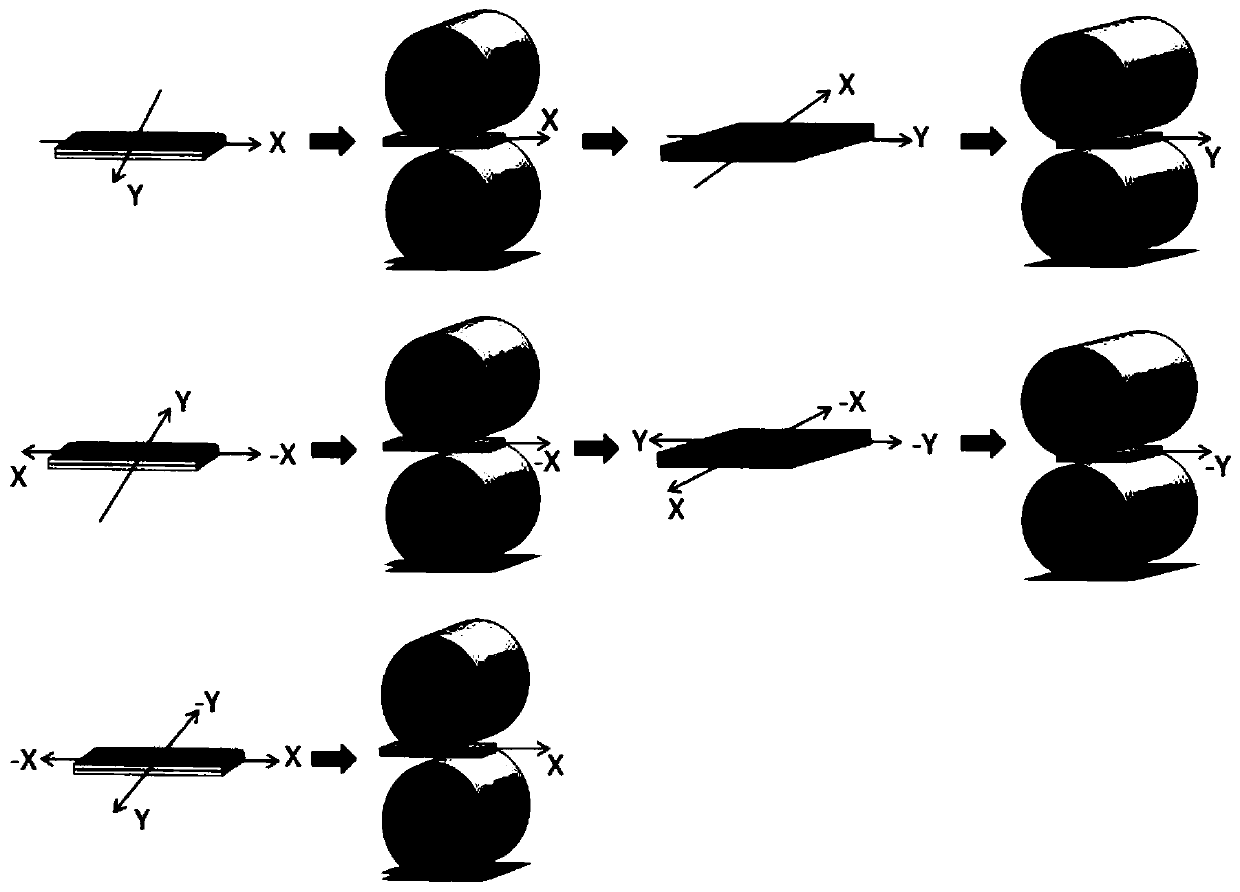

[0017] In the first step, the stainless steel / carbon steel clad plate is rolled using a four-roll mill. Mark the direction of the first rolling schedule on the stainless steel / carbon steel clad plate to be rolled as X, and then carry out the first rolling along the X direction. Among them: the roll temperature is set to room temperature, the rolling speed is 1m / s, the rolling temperature is set to 1000°C, the speed ratio of the upper and lower rolls is set to 1.0, the reduction rate is 30%, and the number of passes is set to 1;

[0018] Rotate 90°, 180°, and 270° clockwise from the X direction to set the Y, -X, -Y directions in turn, and then carry out the second rolling.

[0019] The second step is to set the rolling direction of the stainless steel / carbon steel composite plate after the first rolling to Y, -X, -Y, and X directions for the second rolling, and roll one pass in each direction. Wherein: the rolling speed is 1m / s, the speed ratio of the upper and lower rolls is ...

Embodiment 2

[0021] In the first step, the titanium / steel clad plate is rolled using a four-roll mill. Mark the direction of the first rolling schedule on the titanium / steel clad plate to be rolled as X, and then carry out the first rolling along the X direction. Among them: the roll temperature is set to room temperature, the rolling temperature is set to 900°C, the rolling speed is set to 1m / s, the speed ratio of the upper and lower rolls is set to 1.0, the reduction rate is set to 30%, and the number of passes is set is 1.

[0022] Rotate 90°, 180°, and 270° clockwise from the X direction to set the Y, -X, -Y directions in turn, and then carry out the second rolling.

[0023] The second step is to set the rolling direction of the titanium / steel clad plate after the first rolling to Y, -X, -Y, and X directions for the second rolling, and roll one pass in each direction. Among them: the rolling speed is 1m / s, the speed ratio of the upper and lower rolls is set as 1.0, and the reduction ...

Embodiment 3

[0025] In the first step, the copper / aluminum clad plate is rolled using a four-roll mill. Mark the direction of the first rolling rule on the copper-aluminum composite plate to be rolled as X, and then carry out the first rolling. Among them: the roll temperature is set to room temperature, the rolling temperature is set to 500°C, the rolling speed is set to 1m / s, the speed ratio of the upper and lower rolls is set to 1.0, the reduction rate is set to 25%, and the number of passes is set is 1;

[0026] Rotate 90°, 180°, and 270° clockwise from the X direction to set the Y, -X, -Y directions in turn, and then carry out the second rolling.

[0027] In the second step, the copper-aluminum composite plate after the first rolling is set to be rolled in the direction of Y, -X, -Y, and X for the second rolling, and each direction is rolled once. Among them: the rolling speed is set to 1m / s, the speed ratio of the upper and lower rolls is set to 1.0, and the reduction rate is 15%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com