Intelligent device and method for correcting trapezoidal defects of slab section in real time in online manner

An intelligent device, trapezoidal technology, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced casting yield, reduced economic benefits, cracks in corners, etc., to reduce internal defects problems, improve production efficiency and quality, and achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] It should be noted that the structure, ratio, size, etc. shown in this specification are only used to match the content disclosed in the specification for people familiar with this technology to understand and read, and are not used to limit the implementation of the present invention. Any structural modification, proportional relationship change or size adjustment should still fall within the scope of the technical content disclosed in the present invention without affecting the effects and objectives that the present invention can produce. .

[0052] At the same time, the terms such as "upper", "lower", "left", "right", "middle" and "one" cited in this specification are only for the convenience of description and are not used to limit the text. The scope of implementation of the invention, the change or adjustment of the relative relationship, shall be regarded as the scope of implementation of the invention without substantial changes to the technical content.

[0053] T...

Embodiment 1

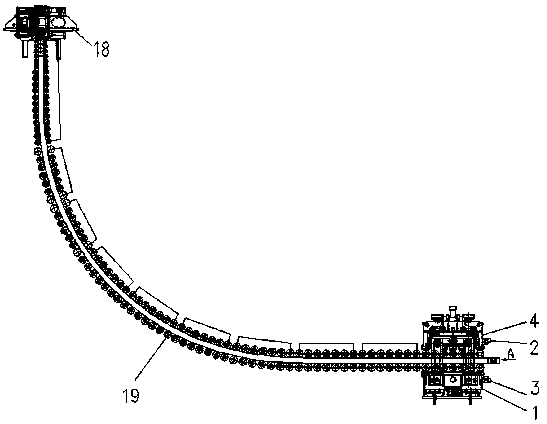

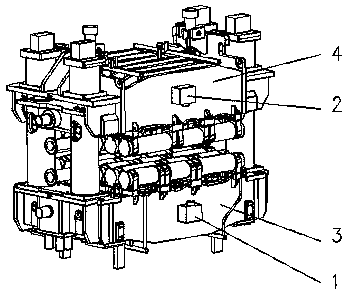

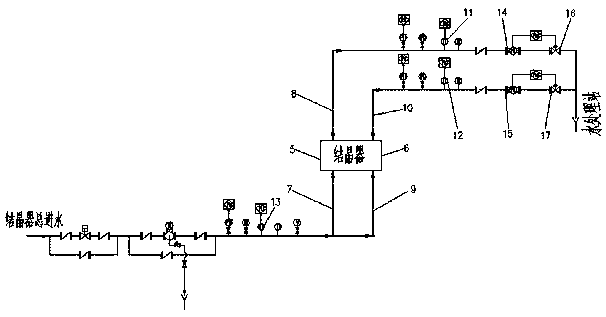

[0055] Such as figure 1 , 2 As shown in 4, the present invention discloses an intelligent device for correcting trapezoidal defects of slab section on-line in real time. It includes a crystallizer 18 and a sector 19, wherein the crystallizer is arranged at the top of the sector and also includes an infrared measuring device and crystallizer cooling. Water system, the infrared measuring device includes a first infrared measuring device 1 and a second infrared measuring device 2, wherein the first infrared measuring device 1 is arranged on the outer arc 3 of the sector segment at the end, and the second infrared measuring device 2 is arranged on At the end of the sector-shaped inner arc 4, the crystallizer cooling water system includes a crystallizer cooling water calculation module and a crystallizer cooling water PLC control module, and the first infrared measuring device 1 and the second infrared measuring device 2 are electrically connected respectively The crystallizer coolin...

Embodiment 2

[0057] Such as figure 1 , 2 As shown in 4, the present invention discloses an intelligent device for correcting trapezoidal defects of slab section on-line in real time. It includes a crystallizer 18 and a sector 19, wherein the crystallizer is arranged at the top of the sector and also includes an infrared measuring device and crystallizer cooling. Water system, the infrared measuring device includes a first infrared measuring device 1 and a second infrared measuring device 2, wherein the first infrared measuring device 1 is arranged on the outer arc 3 of the sector segment at the end, and the second infrared measuring device 2 is arranged on At the end of the sector-shaped inner arc 4, the crystallizer cooling water system includes a crystallizer cooling water calculation module and a crystallizer cooling water PLC control module, and the first infrared measuring device 1 and the second infrared measuring device 2 are electrically connected respectively The crystallizer coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com