Liquid-phase synthesis K2.15MgFe0.05Cu0.05Al0.2B0.2Ti0.02Si4.58O12 potassium fast ion conductor and preparation method

An ionic conductor, liquid phase synthesis technology, applied in chemical instruments and methods, boron compounds, boron oxide compounds, etc., to achieve the effect of reducing grain boundary voids and reducing migration activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

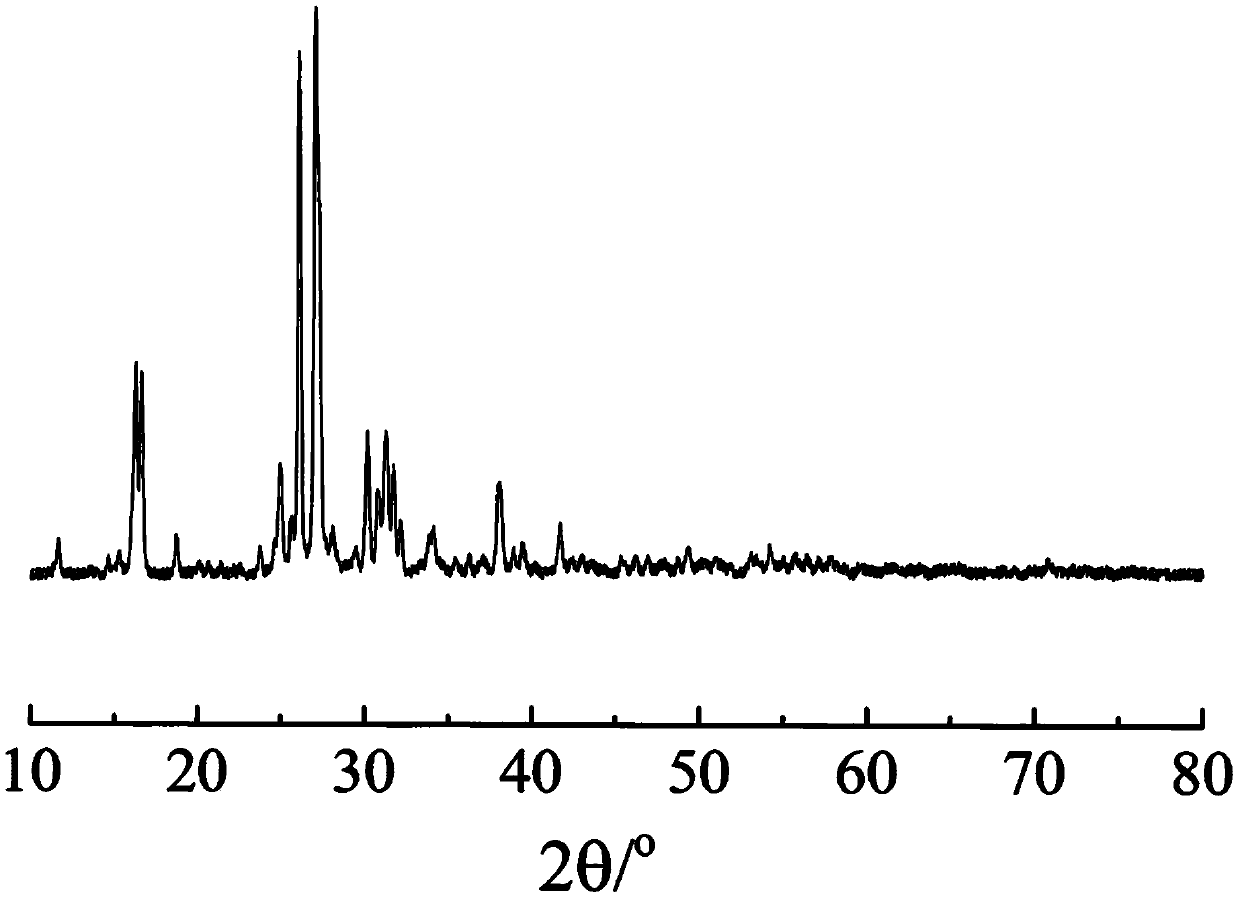

Image

Examples

Embodiment 1

[0011] Embodiment 1: the solid KNO 3 : Fe(NO 3 ) 3 9H 2 O: Cu(NO 3 ) 2 ·3H 2 O: boric acid: Al(NO 3 ) 3 9H 2 O:Mg(NO 3 ) 2 ·6H 2 O according to K 2.15 MgFe 0.05 Cu 0.05 Al 0.2 B 0.2 Ti 0.02 Si 4.58 o 12 The ratio of the stoichiometric molar ratio of the corresponding elements in the mixture is uniformly mixed, while vigorously stirring, add deionized water until all solid substances are dissolved, record the mass of the added deionized water, and then continue to add the recorded deionized water Deionized water with a mass of 1.0 times the mass and stirred evenly, then continue to stir and add tartaric acid whose amount is 1.6 times the total amount of all metal ions and stir well until completely dissolved; record this solution as solution A; it will meet K 2.15 MgFe 0.05 Cu 0.05 al 0.2 B 0.2 Ti 0.02 Si 4.58 o 12 Tetraethyl orthosilicate and tetrabutyl titanate of the stoichiometric ratio are dissolved in absolute ethanol whose volume is 1.1 times th...

Embodiment 2

[0012] Embodiment 2: the solid KNO 3 : Fe(NO 3 ) 3 9H 2 O: Cu(NO 3 ) 2 ·3H 2 O: boric acid: Al(NO 3 ) 3 9H 2 O:Mg(NO 3 ) 2 ·6H 2 O according to K 2.15 Fe 0.05 MgCu 0.05 Al 0.2 B 0.2 Ti 0.02 Si 4.58 o 12 The ratio of the stoichiometric molar ratio of the corresponding elements in the mixture is uniformly mixed, while vigorously stirring, add deionized water until all solid substances are dissolved, record the mass of the added deionized water, and then continue to add the recorded deionized water Deionized water with a mass of 1.5 times the mass and stirred evenly, then continue to stir and add tartaric acid whose amount is 2.4 times the total amount of all metal ions and stir well until completely dissolved; record this solution as solution A; it will meet K 2.15 MgFe 0.05 Cu 0.05 Al 0.2 B 0.2 Ti 0.02 Si 4.58 o 12 Tetraethyl orthosilicate and tetrabutyl titanate of the stoichiometric ratio are dissolved in absolute ethanol whose volume is 1.4 times th...

Embodiment 3

[0013] Embodiment 3: the solid KNO 3 : Fe(NO 3 ) 3 9H 2 O: Cu(NO 3 ) 2 ·3H 2 O: boric acid: Al(NO 3 ) 3 9H 2 O:Mg(NO 3 ) 2 ·6H 2 O according to K 2.15 MgFe 0.05 Cu 0.05 Al 0.2 B 0.2 Ti 0.02 Si 4.58 o 12 The ratio of the stoichiometric molar ratio of the corresponding elements in the mixture is uniformly mixed, while vigorously stirring, add deionized water until all solid substances are dissolved, record the mass of the added deionized water, and then continue to add the recorded deionized water Deionized water with a mass of 1.2 times the mass and stirred evenly, then continue to stir and add tartaric acid whose amount is 2.2 times the total amount of all metal ions and stir well until completely dissolved; record this solution as solution A; it will meet K 2.15 MgFe 0.05 Cu 0.05 Al 0.2 B 0.2 Ti 0.02 Si 4.58 o 12Tetraethyl orthosilicate and tetrabutyl titanate of the stoichiometric ratio are dissolved in absolute ethanol whose volume is 1.3 times the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com