Method for removing organic matters in water

A technology for removing organic matter and water, applied in water pollutants, chemical instruments and methods, water/sewage treatment, etc. It can solve the problem of less research on the degradation efficiency of organic pollutants, less research on dithionite, and a single activation method. and other problems, to achieve the effect of large application potential, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

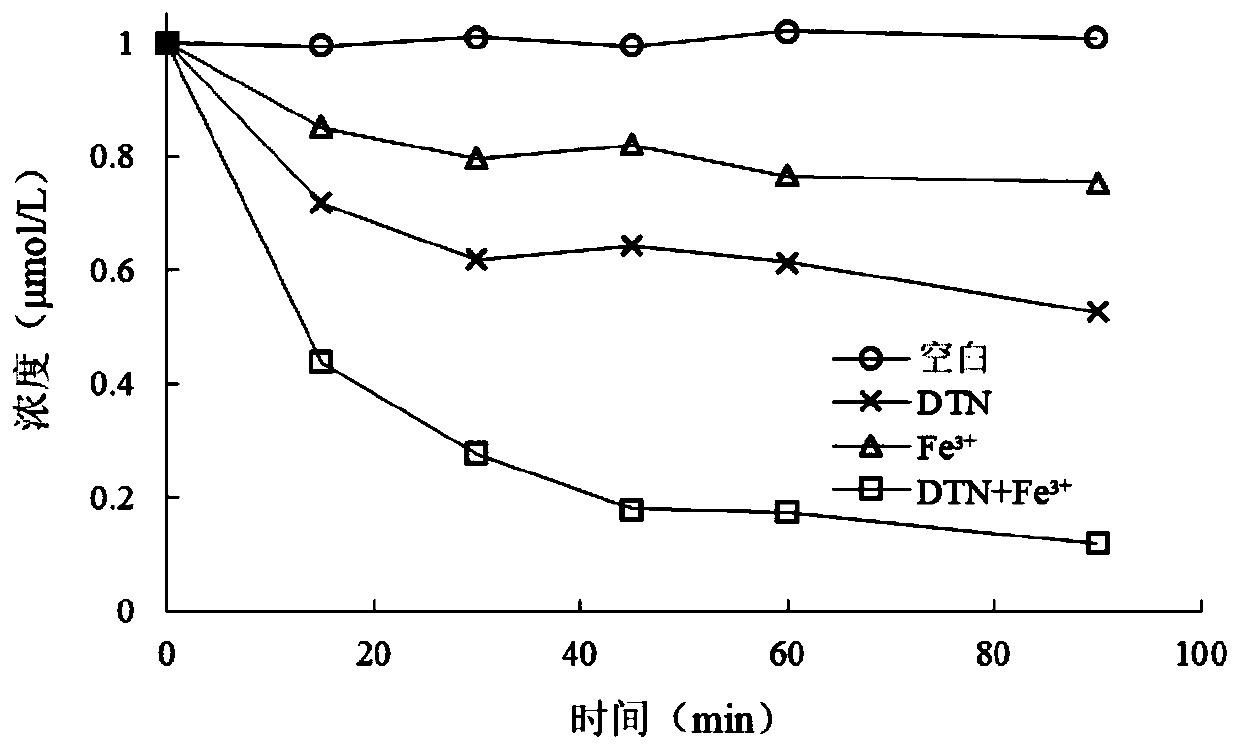

[0041] Example 1: Degradation of tetrabromobisphenol A by activation of dithionite by iron ions

[0042] Take four brown opaque reactors, add tetrabromobisphenol A solution to it until its concentration reaches 1 μmol / L, use 0.1mol / L sulfuric acid and 0.1mol / L sodium hydroxide to adjust the pH to 7, and react in a constant temperature reaction It is carried out in a tank, the temperature is adjusted to 30°C, and the four reactors are stirred at a slow speed at the same time to ensure their uniform reaction. Reactor 1 is a blank control group, add sodium dithionite (DTN for short) solution to reactor 2 to make the concentration reach 100 μmol / L, and add ferric sulfate solution to reactor 3 to make the concentration reach 100 μmol / L , add sodium dithionite solution to reactor 4 to make the concentration reach 100 μmol / L, and add ferric sulfate solution to make the concentration reach 25 μmol / L. Take samples at 15, 30, 45, 60, and 90 minutes respectively, and use a high-performa...

Embodiment 2

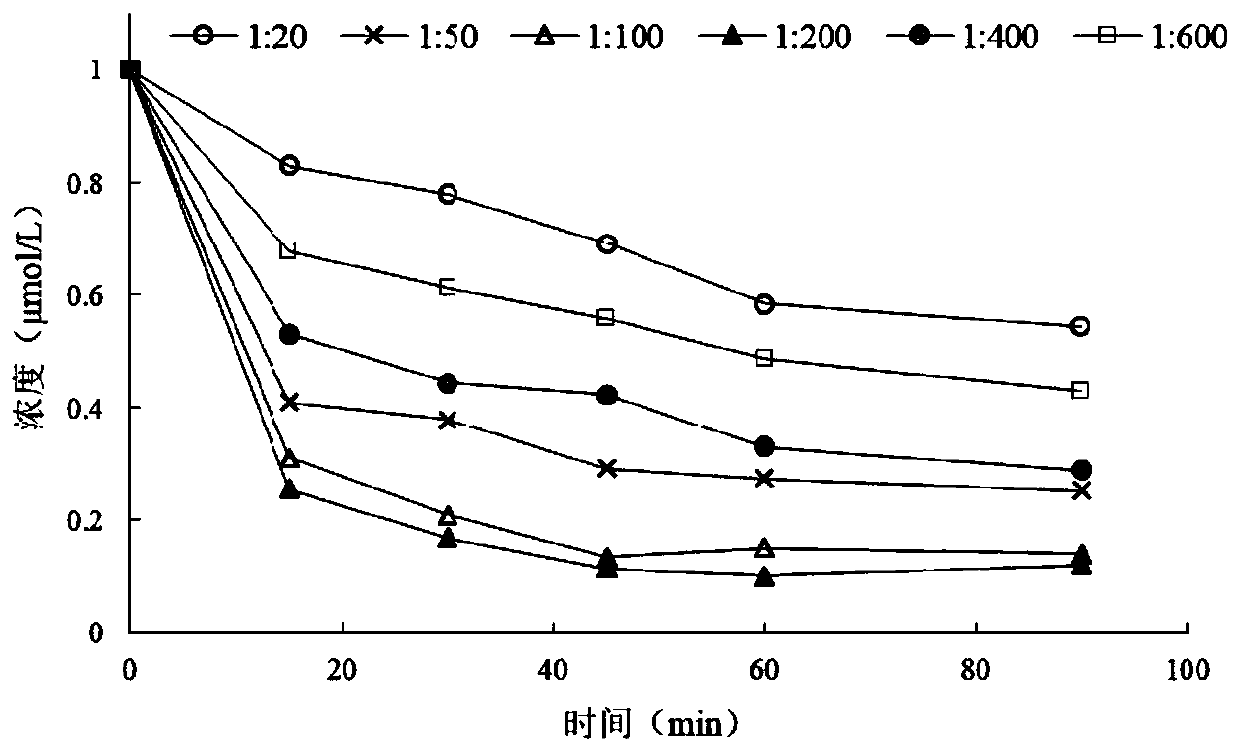

[0044] Example 2: Dithionite Dosage

[0045]Take six brown opaque reactors, add tetrabromobisphenol A solution to it until its concentration reaches 1 μmol / L, use 0.1mol / L sulfuric acid and 0.1mol / L sodium hydroxide to adjust the pH to 7, and react in a constant temperature reaction It is carried out in a tank, the temperature is adjusted to 30°C, and the six reactors are stirred at a slow speed at the same time to ensure uniform reaction. Sodium dithionite (DTN for short) solution and ferric sulfate solution were added to the six reactors respectively so that the concentrations of both reached 20, 50, 100, 200, 400, 600 μmol / L. Take samples at 15, 30, 45, 60, and 90 minutes respectively, and use a high-performance liquid chromatograph to detect the residual concentration of tetrabromobisphenol A. The detection results are as follows: figure 1 shown.

[0046] Depend on figure 2 It can be seen that, in the time of 90min, along with the increase of dithionite dosage, the rem...

Embodiment 3

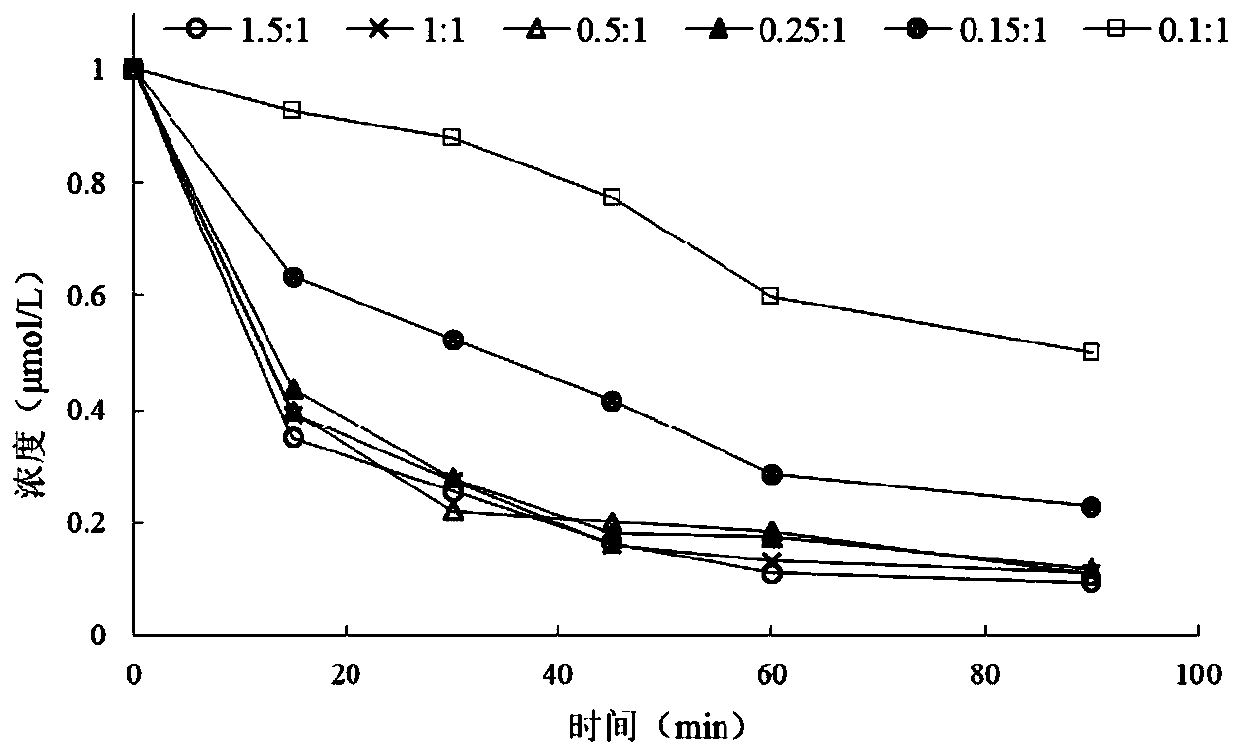

[0047] Embodiment 3: iron ion dosage

[0048] Take six brown opaque reactors, add tetrabromobisphenol A solution to it until its concentration reaches 1 μmol / L, use 0.1mol / L sulfuric acid and 0.1mol / L sodium hydroxide to adjust the pH to 7, and react in a constant temperature reaction It is carried out in a tank, the temperature is adjusted to 30°C, and the six reactors are stirred at a slow speed to ensure uniform reaction. Add sodium dithionite (DTN) solution to the five reactors to make the concentration reach 100 μmol / L, and add ferric sulfate solution to make the concentration reach 10, 15, 25, 50, 100, 150 μmol / L respectively. Take samples at 15, 30, 45, 60, and 90 minutes respectively, and use a high-performance liquid chromatograph to detect the residual concentration of tetrabromobisphenol A. The detection results are as follows: image 3 shown.

[0049] Depend on image 3 It can be seen that at 90 minutes, with the continuous increase of the iron ion concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com