Low-sulfur-resistant low-temperature carbon-based denitration catalyst as well as preparation method and application thereof

A denitration catalyst and low-temperature technology, applied in the field of flue gas denitrification, can solve the problems of complex preparation process, high energy consumption, high catalyst cost, etc., and achieve the effect of simple preparation method, high efficiency, low cost of raw materials and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, the IAC of the impregnated activated carbon sample loaded with Mn and Fe is 5%Mn0.5%Fe / HAC.

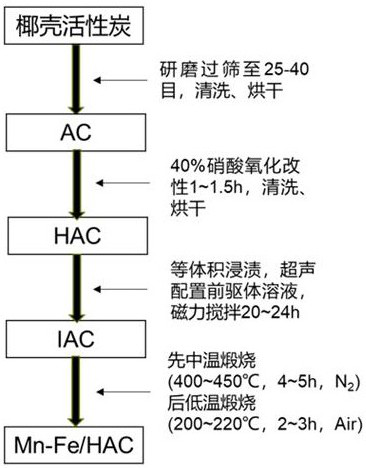

[0034] For the preparation method of the low-sulfur-resistant low-temperature carbon-based denitration catalyst, refer to figure 1 ,Specific steps are as follows:

[0035] Step 1. Crushed, ground, and sieved coconut shell activated carbon to 25-40 mesh particles, washed 3-4 times with deionized water, and dried in an oven at 105°C for 12 hours to obtain sample AC.

[0036] Step 2. Put the AC in a constant temperature water bath at 80°C with 40 wt.% HNO 3 The solution (according to 6 mL nitric acid solution / g activated carbon) was impregnated and stirred for 1 h, then washed with deionized water until neutral, and then dried in an oven at 105 °C for 12 h to prepare the sample HAC.

[0037] Step 3. Under the ultrasonic environment at room temperature, prepare the solution according to the equal volume impregnation method, take 2.47g 50 wt.% Mn(NO 3 ) 2 and 0....

Embodiment 2

[0044] Same as Example 1, the difference is that 2.47g 50 wt.% Mn(NO 3 ) 2 , 0.30g Fe(NO 3 ) 3 .9H 2 O and 11.28 g HAC, 5%Mn1%Fe / HAC was prepared, and its denitrification efficiency is shown in Table 1. It can be seen from the table that its denitrification efficiency is lower than 90% between 160-240°C, and the effect ratio is 5 %Mn0.5%Fe / HAC catalyst is poor.

Embodiment 3

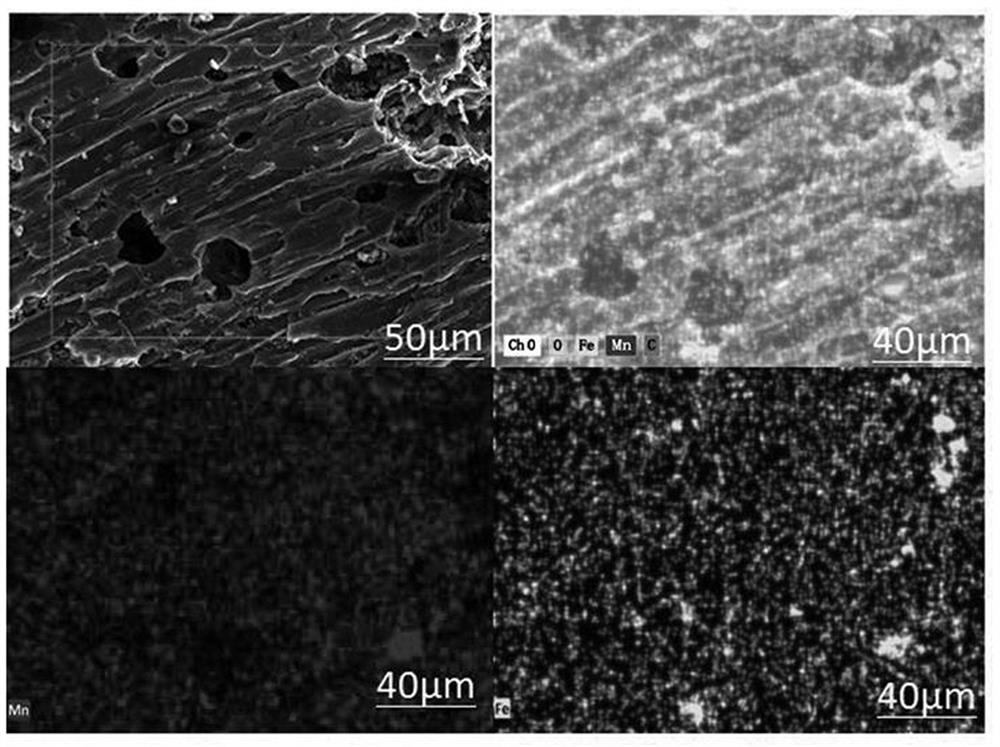

[0046] Same as Example 1, the difference is that 3.46g 50 wt.% Mn(NO 3 ) 2 , 0.15g Fe(NO 3 ) 3 .9H 2 O and 11.1 g HAC were prepared to obtain 7%Mn0.5%Fe / HAC. The denitrification efficiency is shown in Table 1. It can be seen from the table that it can maintain more than 90% denitrification efficiency between 140-240°C. The SEM-Mapping characterization diagram of the carbon-based catalyst obtained in this example can be found in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com