Screw sliding plunger type step temperature control melting electrostatic spinning device

A melting electrostatic and sliding column technology, which is used in the melting of filament raw materials, textile and papermaking, filament/thread forming, etc. Stretching, affecting shape and size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

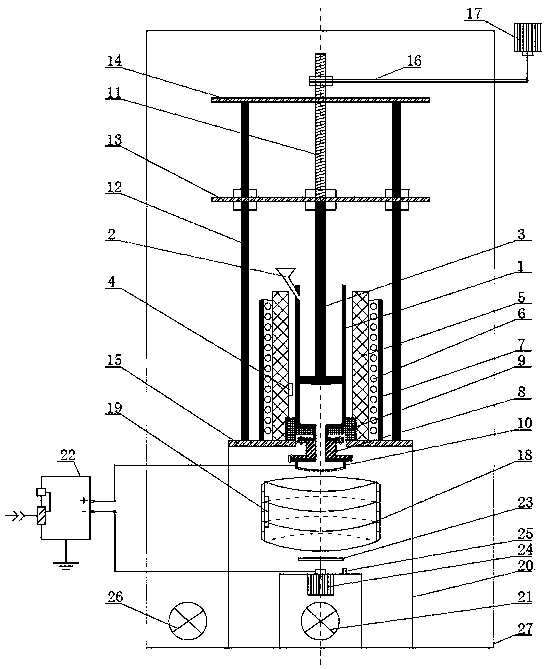

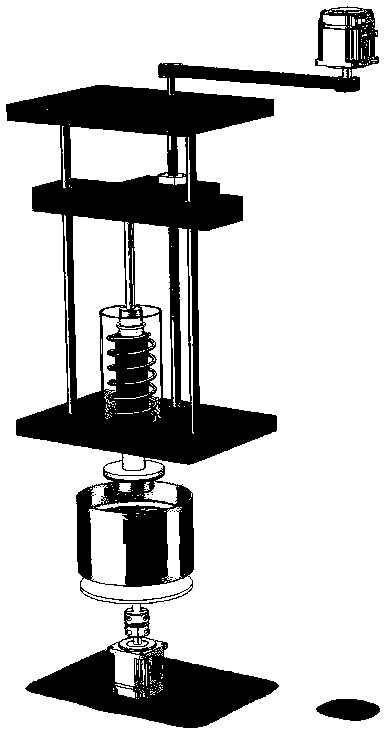

[0006] The present invention will be described in detail below in conjunction with the accompanying drawings and examples: A screw-screw sliding plunger-type stepped temperature-controlled melting electrospinning equipment according to the present invention has a structure as shown in the attached figure 1 As shown, it includes a melting heating unit, a screw drive unit, a step temperature control unit and an electrospinning unit, and it is characterized in that: the melting heating unit includes a stainless steel cylinder 1, a feeding hopper 2, a stainless steel push rod 3, a thermocouple Sensor A 4 , insulation layer 5 , high frequency coil 6 , electromagnetic shield 7 , insulation isolation module 8 , support chassis 9 and discharge nozzle 10 . The stainless steel cylinder 1 is used to store molten materials; the feed hopper 2 is located on the side of the upper part of the stainless steel cylinder 1, and is used for feeding materials; the chassis at the bottom of the stainl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com