Sensor LGA (Land Grid Array) packaging structure

A technology of LGA packaging and packaging structure, which is applied in the direction of semiconductor devices, electrical solid devices, semiconductor/solid device components, etc., can solve problems affecting product performance, large internal stress, high cost, etc., and reduce electrical signal data drift and barrier effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below with examples and accompanying drawings, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

[0023] The embodiment of the present invention discloses a sensor LGA packaging structure, so as to optimize the electrical signal drift problem of the transducer chip output caused by the influence of substrate stress during mass production.

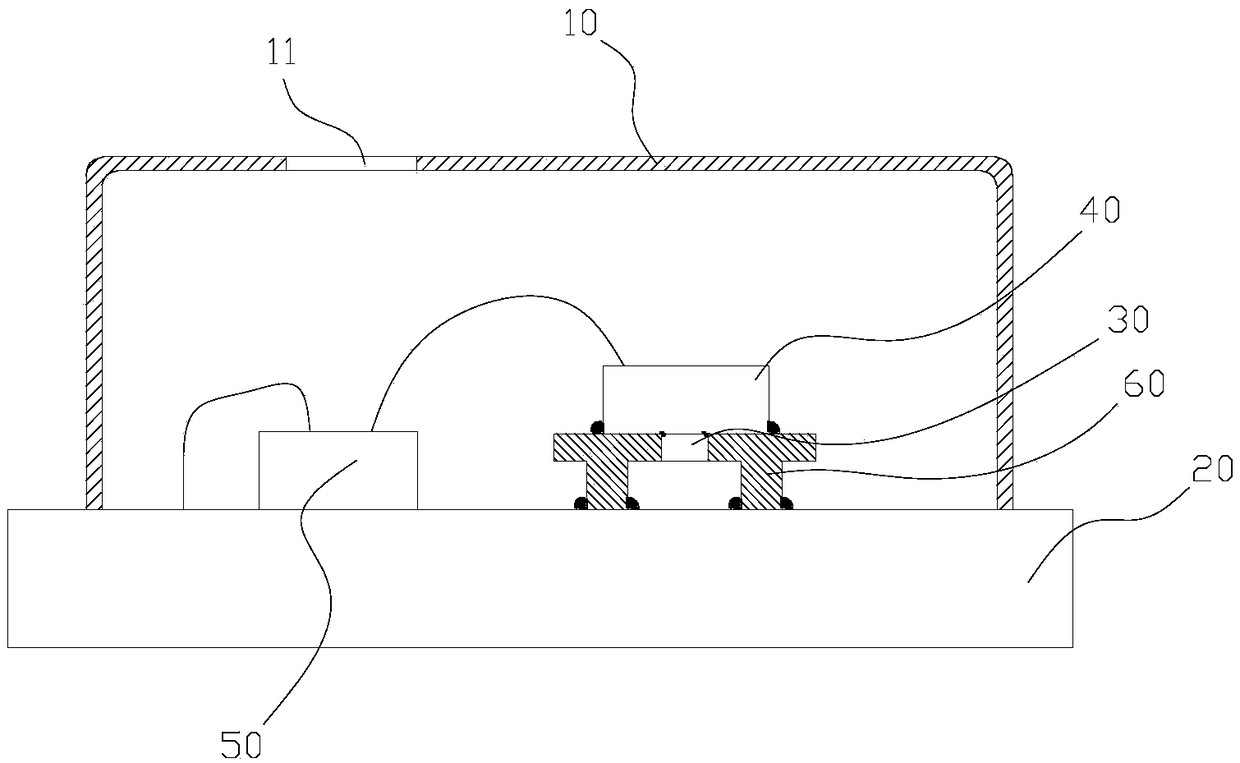

[0024] Such as figure 1 As shown, the sensor LGA packaging structure of this embodiment includes a housing 10 and a substrate 20, the substrate 20 and the housing 10 form a packaging structure, the packaging structure is used to package the transducer chip 40, and the sensor LGA packaging structure also includes a gasket 60, The gasket 60 is used to bond the transducer chip 40, and the bonding adopts an adhesive method. The upper and lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com