Method for extracting thin film Young modulus of multilayer cantilever beam material on basis of Newton downhill method

A technology of Young's modulus and extraction method, which is applied to the analysis of materials, measuring devices, instruments, etc., can solve the problems of non-convergence, convergence only in some areas, and difficulty in giving an initial value to ensure convergence, so as to expand the scope and improve The defect of local convergence and the effect of reducing time complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

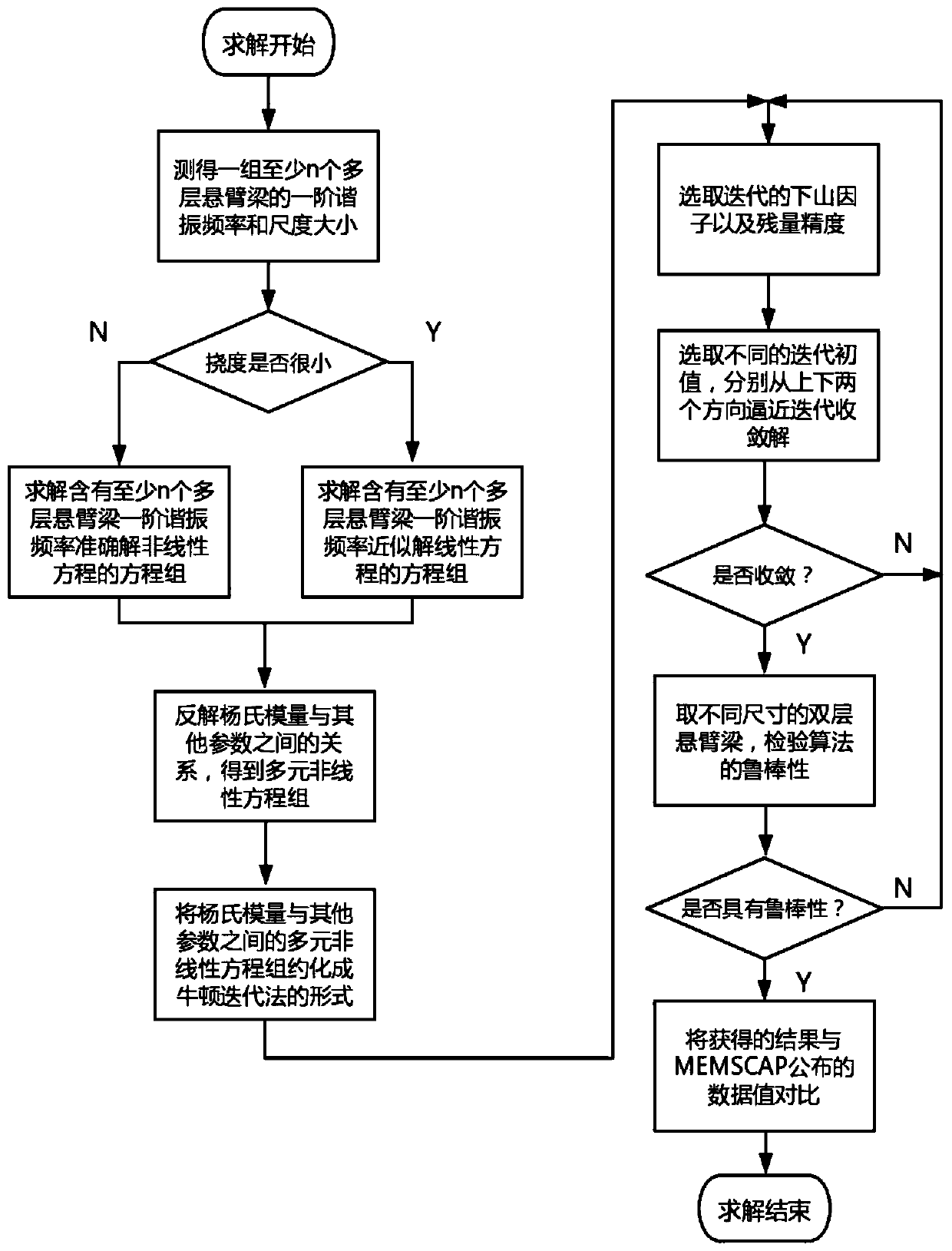

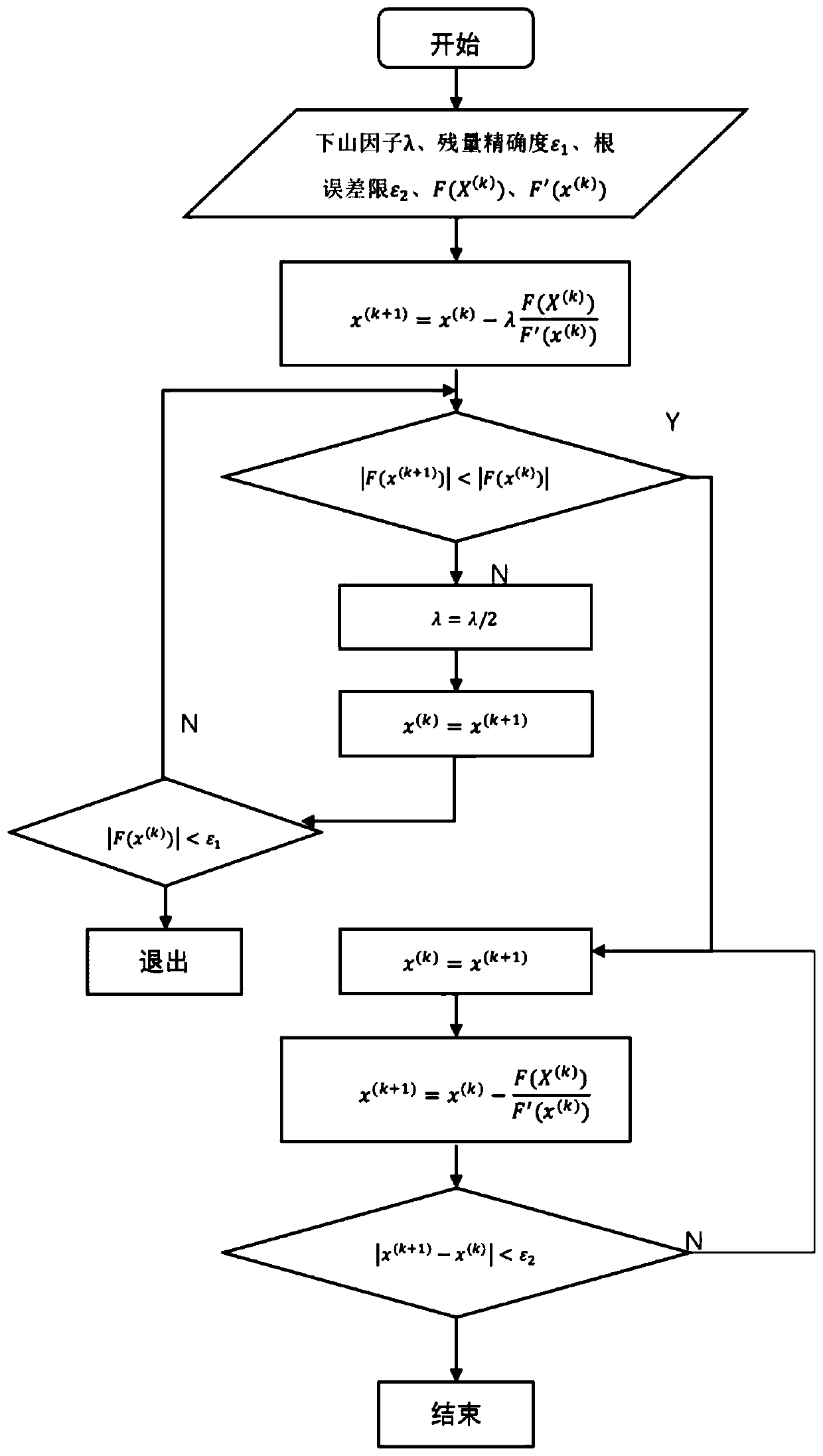

[0025] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

[0026] (1) Introduction to the physical quantity of the cantilever beam

[0027] When the film width and its thickness satisfy b i i That is, for narrow beams, the equivalent Young's modulus is the Young's modulus E i itself; when the film width and its thickness satisfy b i ≥5h i That is, when the beam is wide, the equivalent Young's modulus is a function of Young's modulus and Poisson's ratio v i relationship, that is The equivalent Young's modulus The relationship between film thickness and its width is:

[0028]

[0029] equivalent residual stress for Before undergoing the release process (that is, when no deformation occurs), the length of the beam is l. The width of the i-th film material is w i , with thickness h i , the material density is ρ i , Young's modulus is E i . The bottom surface of the multi-layer beam (that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com