High-power laser Donut mode shaping device and shaping lens

A shaping device and high-power technology, applied in the laser field, can solve problems such as complex structure and difficult processing, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

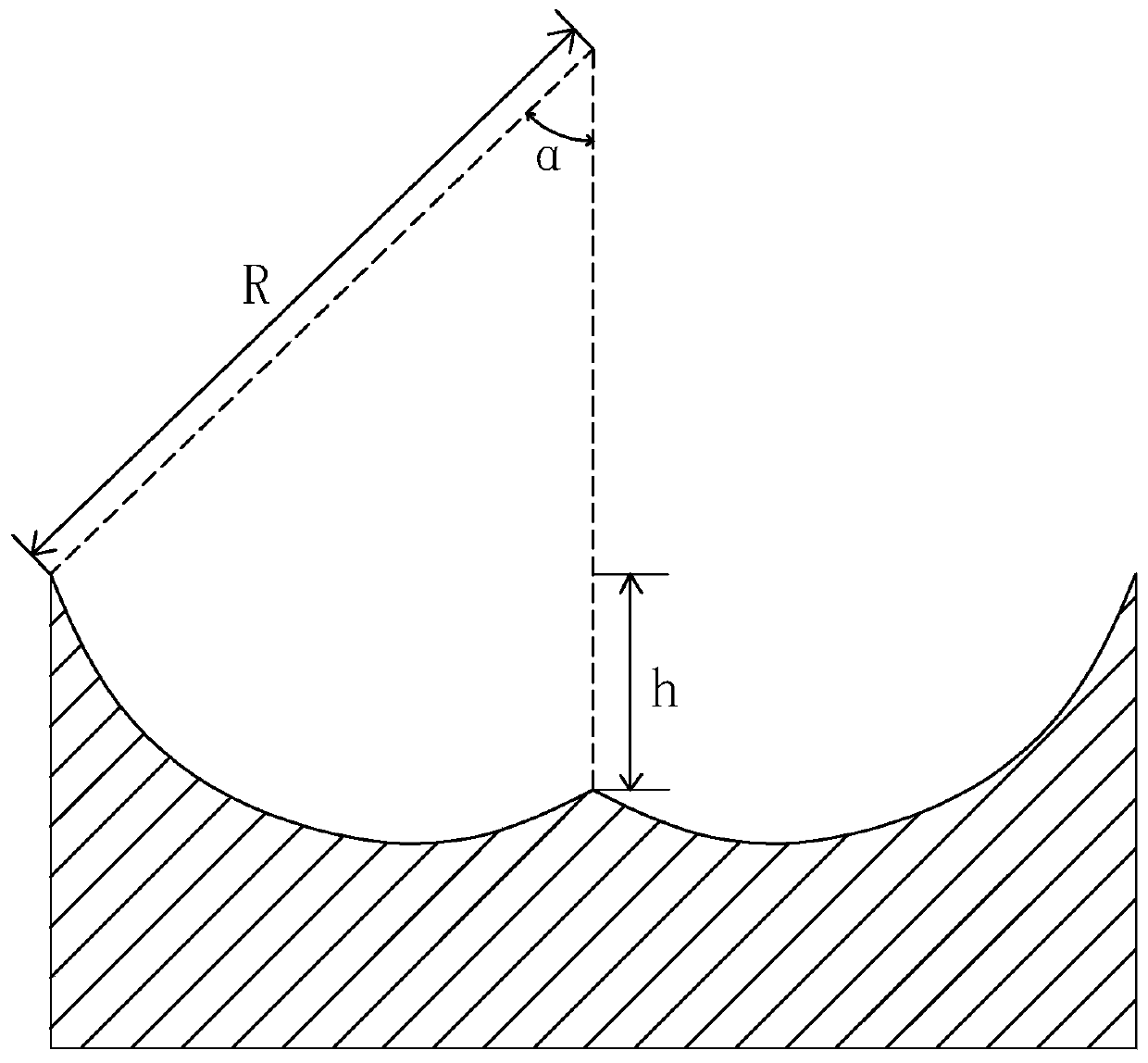

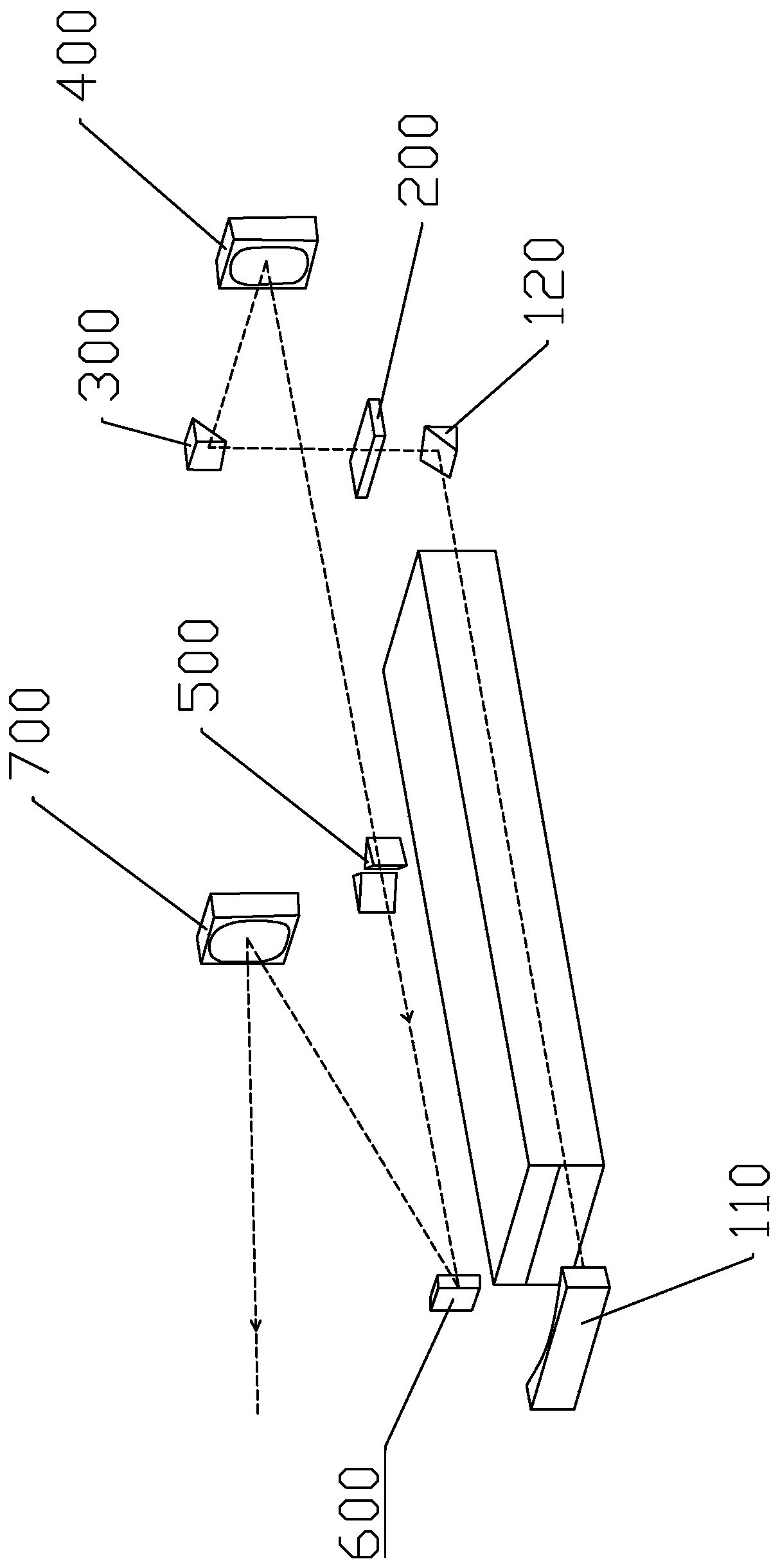

[0016] Embodiment one, refer to figure 1 , figure 2 and image 3 , high power laser Donut mode shaping device, including: high power radio frequency slat CO 2 Laser and shaping mirror 700, the high power radio frequency slats CO 2 The laser is used to output a light beam whose mode is a Gaussian mode, and the light beam is input into the shaping mirror 700. The reflection surface of the shaping mirror 700 is generally convex in the middle and concave in the periphery. The reflection surface passes through the first bus bar 710 to A vertical line is rotated, the first bus bar 710 is an arc line, the radius of curvature R of the first bus bar 710 is 4200mm, and the vertical line passes through the lower end point 712 of the first bus bar 710, The vertical distance h between the upper end point 711 of the first bus bar 710 and the upper end point 711 of the first bus bar 710 is 0.00625 mm, and the central angle α degree of the first bus bar 710 is 0.04°

[0017] The shaping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com