Working condition metering method of cryogenic high-pressure hydrogen storage system

A metering method and technology for hydrogen storage, applied in the directions of calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of metering method without cryogenic high-pressure hydrogen storage system, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

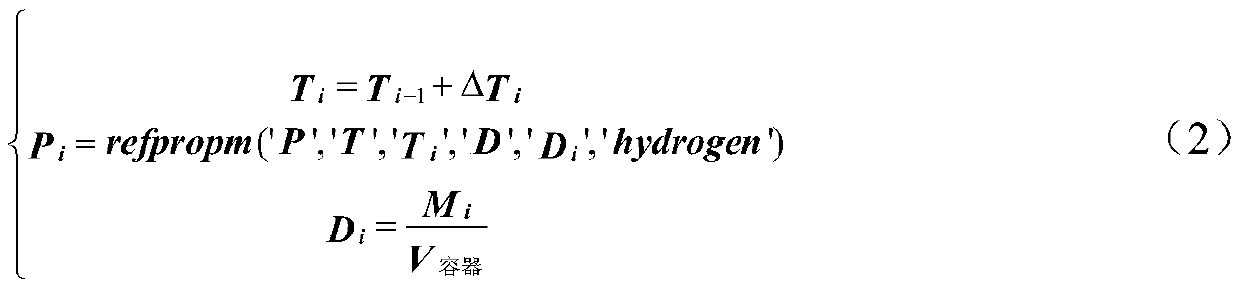

Method used

Image

Examples

example

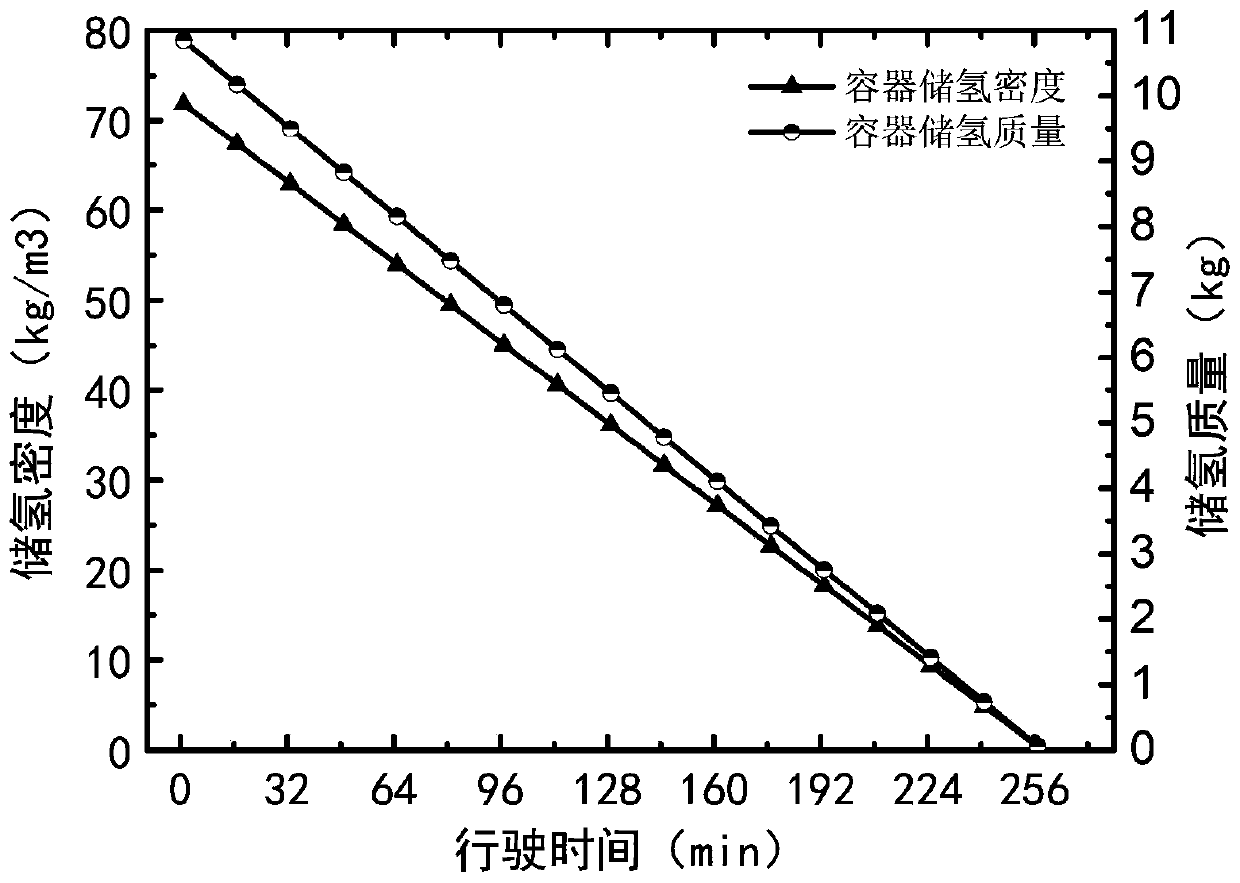

[0063] Model example: Yaxing YBL6818 hydrogen fuel bus

[0064] Initial temperature of the container: 60K (30-100K)

[0065] Inner container pressure: 34.5MPa (a unified pressure standard for performance testing of hydrogen storage means) about 34MPa

[0066] Inner container volume: 151L (110-160L)

[0067] It can be seen from the figure that the hydrogen storage density of the initial state container is 71.8g / L, and the hydrogen storage mass is 10.85kg, which theoretically can make an unloaded 6.6t 8-meter hydrogen-fueled passenger car have a cruising range of about 256km. The hydrogen consumption flow per unit power is 0.02118 (g / (s·kW)) hydrogen consumption per hundred kilometers is 4.24kg. The endurance time is 4.3h.

[0068] The simulation results meet the relevant technical standards of hydrogen fuel vehicles. In the case of a given vehicle example, input the initial temperature and initial pressure of the container to accurately obtain its density and mass, and analyze the consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com