A kind of lead-acid storage battery electrolyte additive and preparation method thereof

An electrolyte additive, lead-acid battery technology, applied in the direction of lead-acid battery, lead-acid battery construction, electrolyte, etc., can solve the problems of discharge capacity reduction, lead-acid battery charge acceptance decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

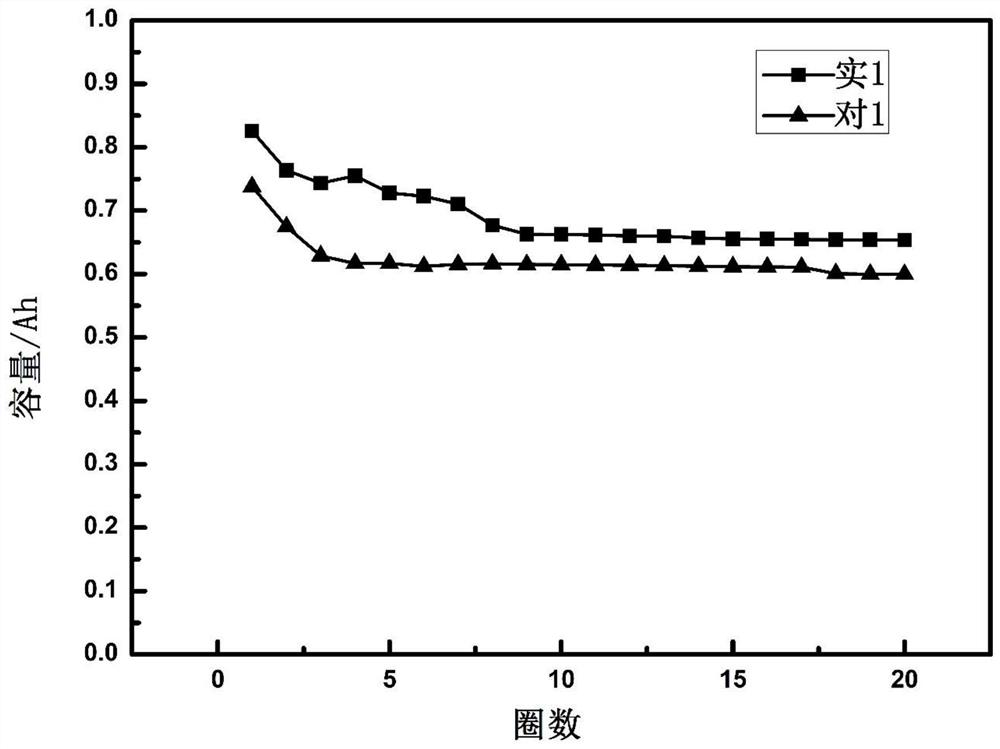

Embodiment 1

[0024] A preparation method of an electrolyte additive for a lead-acid battery, adding concentrated sulfuric acid to ultrapure water to prepare dilute sulfuric acid with a volume of 1L, and adjusting the density of the dilute sulfuric acid to 1.24g / cm 3 3,500 mg of sodium sulfate, 4,000 mg of sodium tripolyphosphate, 4,000 mg of sodium dimercaptosuccinate, 5,000 mg of aspartic acid, and 2,000 mg of methanesulfonic acid were sequentially added to dilute sulfuric acid. Adjust the temperature of the dilute sulfuric acid to 37° C., and stir at a speed of 300 rpm for 5 minutes.

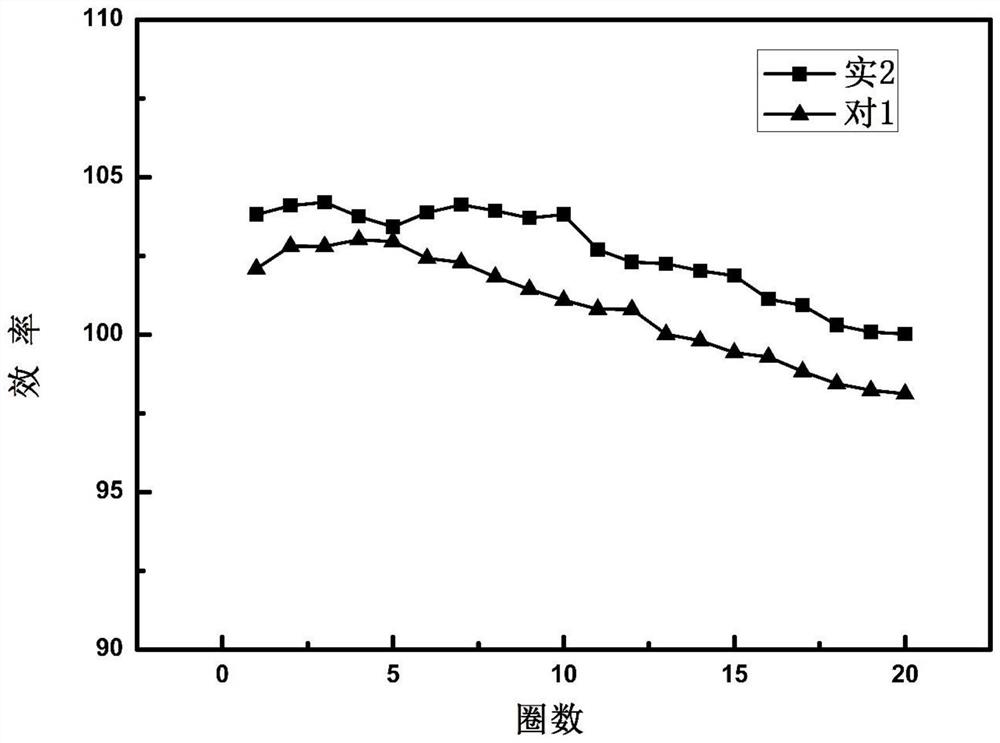

Embodiment 2

[0026] A preparation method of an electrolyte additive for a lead-acid battery, adding concentrated sulfuric acid to ultrapure water to prepare dilute sulfuric acid with a volume of 1L, and adjusting the density of the dilute sulfuric acid to 1.24g / cm 3 3,000 mg of stannous sulfate, 3,500 mg of sodium tripolyphosphate, 3,500 mg of sodium dimercaptosuccinate, 4,000 mg of cysteine, and 2,000 mg of methanesulfonic acid were sequentially added to dilute sulfuric acid. Adjust the temperature of the dilute sulfuric acid to 35° C., and stir at a speed of 400 rpm for 5 minutes.

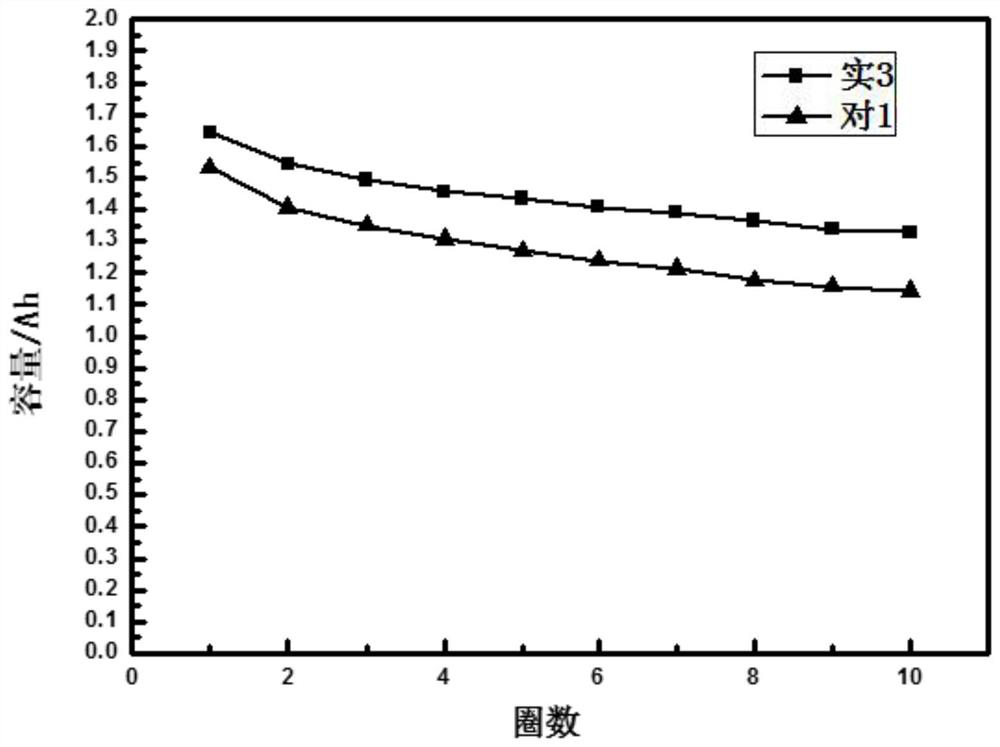

Embodiment 3

[0028] A preparation method of an electrolyte additive for a lead-acid battery, adding concentrated sulfuric acid to ultrapure water to prepare dilute sulfuric acid with a volume of 1L, and adjusting the density of the dilute sulfuric acid to 1.24g / cm 3 3,200 mg of cobalt sulfate, 3,800 mg of sodium tripolyphosphate, 3,200 mg of sodium dimercaptosuccinate, 5,000 mg of threonine, and 3,000 mg of methanesulfonic acid were sequentially added to dilute sulfuric acid. Adjust the temperature of the dilute sulfuric acid to 36° C., and stir at a speed of 320 rpm for 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com