Novel process low temperature denitration reaction system

A reaction system and low-temperature denitrification technology, which is applied in the field of waste incineration power generation flue gas treatment system, can solve the problems that cannot meet the growing needs of waste incineration power generation, and achieve the effect of increasing the contact area and improving the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described in further detail in conjunction with the accompanying drawings.

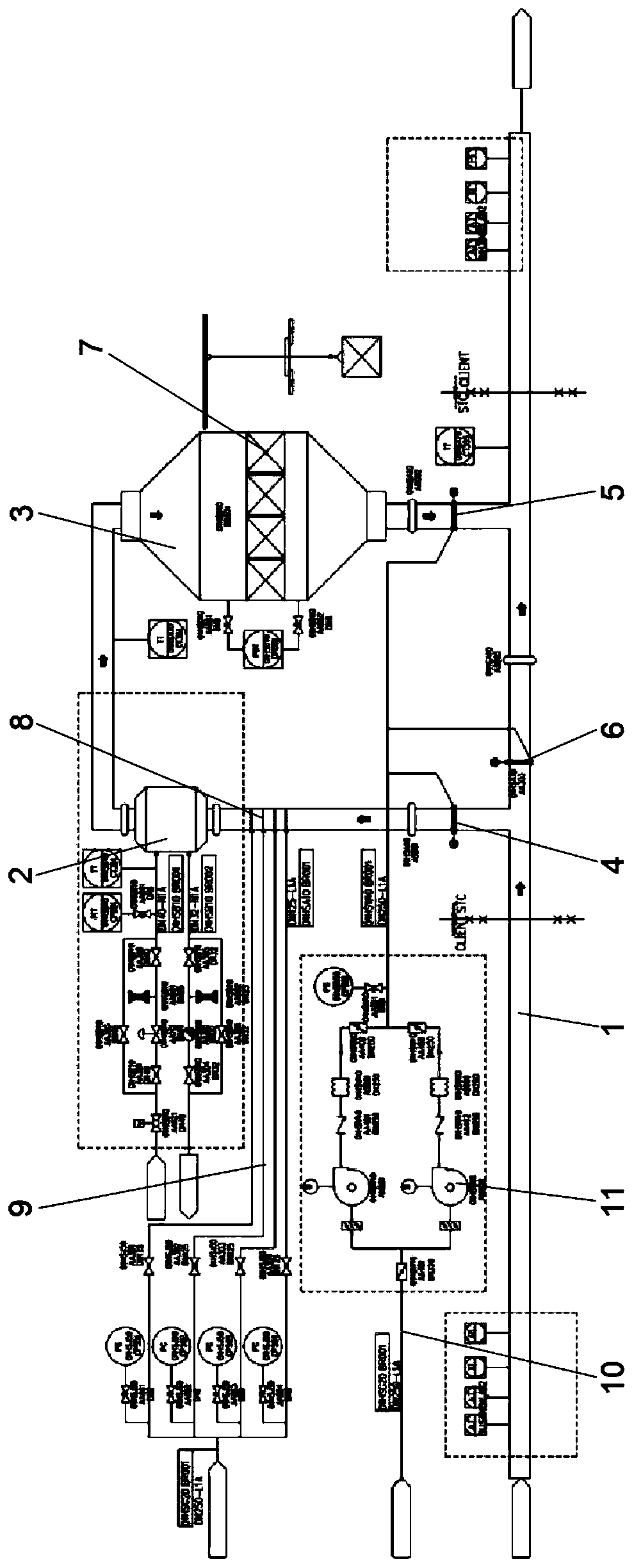

[0015] Such as figure 1 As shown, a new process low-temperature denitration reaction system includes a denitration reaction system body, and the denitration reaction system body includes a flue gas pipeline 1, and a steam heater installed on the flue gas pipeline 1 for further heating flue gas and reducing agent 2 and an SCR reactor 3 arranged on the flue gas pipeline 1 for reducing and denitrifying the heated flue gas, the flue gas pipeline 1 is provided with an inlet baffle door 4 near the entrance of the steam heater 2 , the flue gas pipeline 1 is provided with a gas outlet baffle door 5 near the gas outlet of the SCR reactor 3, and the flue gas pipeline 1 is provided with a steam heater 2 and a bypass valve connected in parallel with the SCR reactor 3. The bypass pipeline is provided with a bypass baffle door 6, and the SCR reactor 3 is fixed with a reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com