A kind of leveling method of semi-technical steel

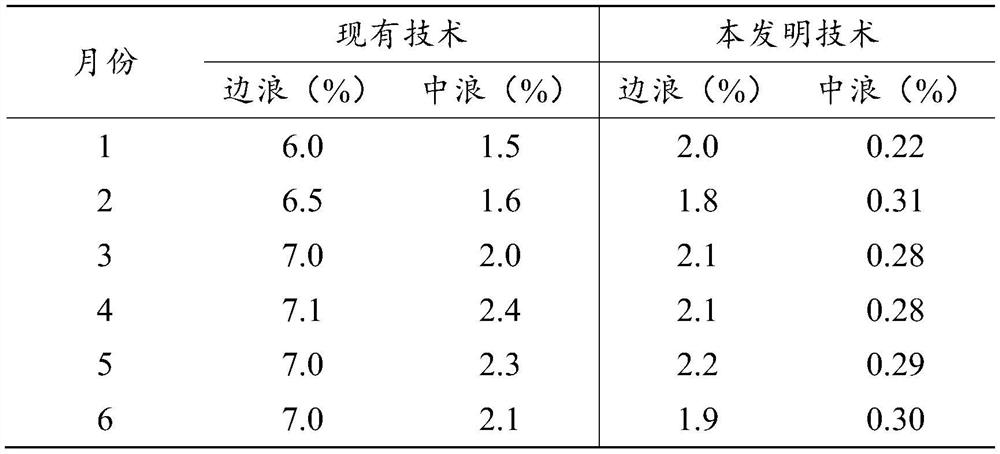

A semi-process and flattening technology, applied in the direction of metal rolling, contour control, etc., can solve the problems of low efficiency and effective control of defect elimination, and achieve the effect of reducing edge wave defects, reducing elongation, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

[0029] The invention provides a method for smoothing semi-technical steel, comprising:

[0030] (1) hot-rolling the thin plate on a hot rolling mill to obtain a hot-rolled steel plate;

[0031] Wherein, hot rolling is carried out by using a 7-stand hot continuous rolling mill; preferably, the tension between each stand is: the first stand and the second stand are 2-3N / mm 2 , the second frame and the third frame are 4-5N / mm 2 , the third frame and the fourth frame are 6-7N / mm 2 , the fourth frame and the fifth frame are 7-8N / mm 2 , the fifth frame and the sixth frame are 10-11N / mm 2 , the sixth frame and the seventh frame are 12-13N / mm 2 The reduction rate of the first frame is 52-55%, the reduction rate of the second frame is 50-52%, the reduction rate of the third frame is 45-48%, and the reduction rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com