Prefabricated energy-saving new residence structure and manufacturing method thereof

A prefabricated and residential technology, applied to building components, building structures, passive houses, etc., can solve problems such as scarcity, long construction period, and difficult construction, so as to achieve simple and quick composition and operation, solve construction problems, and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

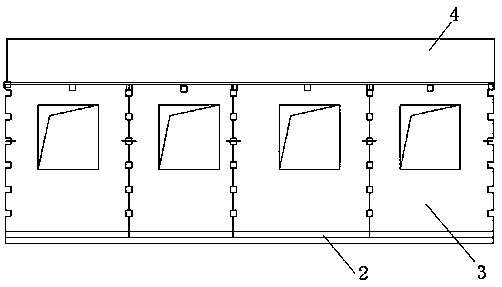

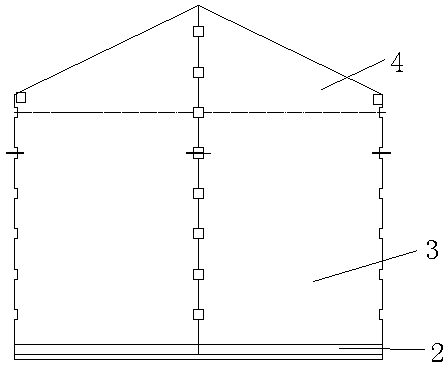

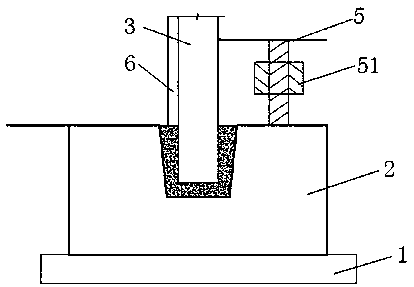

[0049]A prefabricated energy-saving new residential structure, including prefabricated prefabricated foundation board 2, prefabricated wall board 3, integral roof 4, prefabricated floor 5 and exterior wall insulation integrated board 6; wherein, the prefabricated foundation board 2 is made of The prefabricated foundation slab formed by pouring concrete molds in the workshop; the prefabricated foundation slab 2 is used to provide an overall plane support structure, which is paved on the upper part of the foundation cushion, and the adjacent prefabricated foundation slabs 2 are butted with each other; the prefabricated foundation The connection node between the board 2 and the prefabricated wall panel 3 is: a bayonet groove 21 is reserved on the prefabricated foundation board 2, the bottom of the prefabricated wallboard 3 is inserted into the bayonet groove 21, and is filled with concrete. The prefabricated wall panels 3 are prefabricated concrete wall panels molded by casting co...

Embodiment 2

[0051] The differences between this embodiment and Embodiment 1 are:

[0052] The prefabricated energy-saving new residential structure also includes an interior wall decoration integrated board 7, and the interior wall decoration integrated board 7 and the wall board 3 are connected by L-shaped hangers and bolts, and can also be directly pasted and fixed.

Embodiment 3

[0054] A method for manufacturing a prefabricated energy-saving new residential house, comprising the following steps:

[0055] S1. Workshop prefabricated components

[0056] Prefabricate the prefabricated foundation board 2, prefabricated wall board 3, prefabricated floor 5 and exterior wall insulation integrated board 6 in advance in the workshop; the prefabricated light steel keel 41, calcium silicate board 42, waterproof layer 43, Wood strip 44, rock wool insulation board 45 and prefabricated anti-ancient cement tile 46;

[0057] The prefabricated foundation board 2, the prefabricated wall board 3 and the prefabricated floor 5 are all formed by pouring concrete molds in the workshop;

[0058] S2. On-site construction

[0059] On-site trenching and grooving to consolidate the foundation;

[0060] S3. Laying prefabricated foundation slabs

[0061] Laying the prefabricated foundation slabs 2 flat on the foundation cushion, splicing and aligning adjacent prefabricated foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com