Ice-melting snow-removing asphalt mixture, preparation method thereof, ice-melting snow-removing asphalt concrete pavement and construction method thereof

A technology of asphalt mixture and asphalt concrete, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of improving the performance of asphalt concrete for melting ice and snow, affecting the performance of asphalt mixture, and using a large amount of raw materials. Achieve the effect of low overall cost, improve road skid resistance, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Therefore, according to a first aspect of the present invention, in at least one embodiment, a method for preparing ice-melting and snow-melting asphalt mixture is provided, comprising the following steps:

[0059] (a) On the basis of determining the synthetic gradation of the asphalt mixture without adding salts, use the salts as fillers, adjust the gradation of the asphalt mixture by screening the salts, and determine the asphalt ratio a according to the target mix ratio ; On the basis of the asphalt ratio a of the asphalt mixture, the salt is used to replace part of the mineral powder, the mix ratio is designed again, and the optimum asphalt ratio and the asphalt mixture are determined by the Marshall test. Grading;

[0060] (b) adding each raw material in the asphalt mixture mixed with the salt compound according to the mixing sequence, and mixing to obtain the ice-melting and snow-melting asphalt mixture.

[0061] This method adjusts the gradation of the asphalt m...

Embodiment 1

[0131] A construction method for ice-melting and snow-melting asphalt concrete pavement, comprising the following steps:

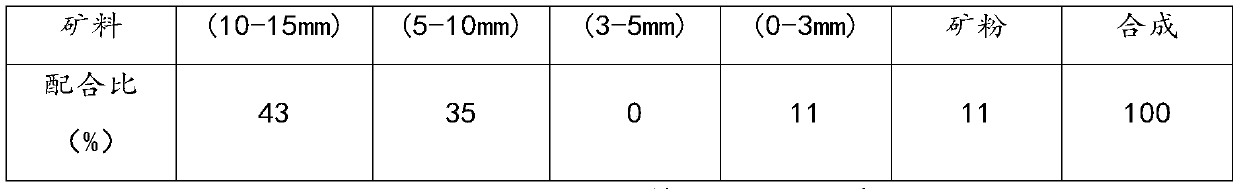

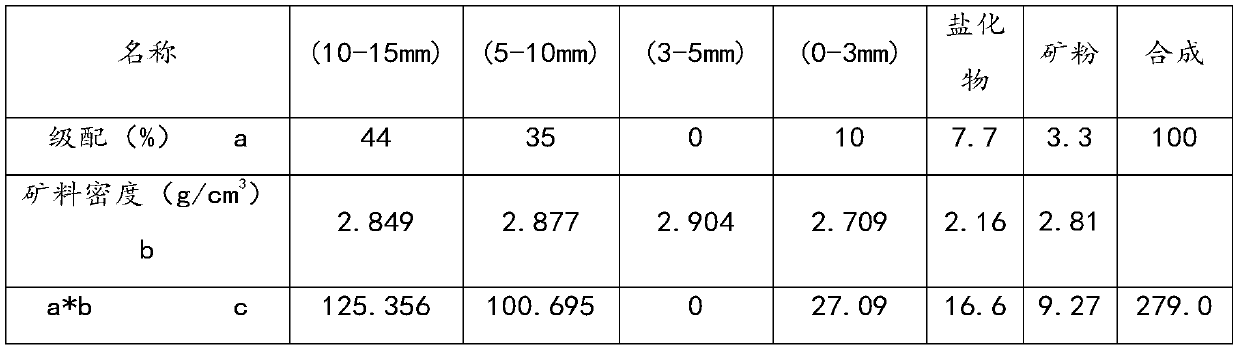

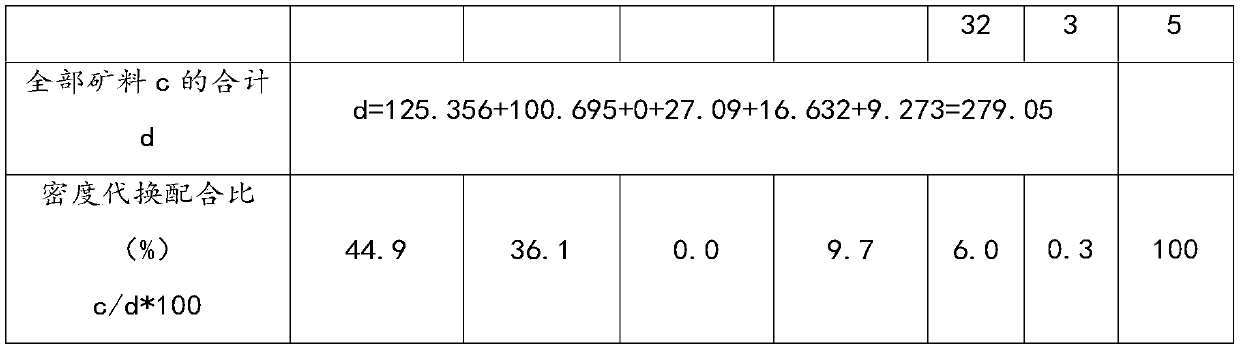

[0132] (a) On the basis of determining the synthetic gradation of SMA-13 asphalt mixture without adding salt compound, the salt compound is used as a filler, and the gradation of the asphalt mixture is adjusted by screening the salt compound, according to the target mix The optimal asphalt ratio determined by the ratio is 6.1%; on the basis of the optimal asphalt ratio of 6.1% in the asphalt mixture, salt is used to replace part of the mineral powder, and the mix ratio is designed again, using 5.8%, 6.0%, 6.1%, and 6.4% The Marshall specimen with a diameter of 101.6mm and a height of 63.5±1.3mm is compacted 55 times on both sides, and the number of specimens in each group is 6. , bitumen saturation, stability and flow value are tested and tested, and the optimum asphalt ratio of the asphalt mixture mixed with salt is determined to be 6.1%, and the corres...

Embodiment 2

[0143] A construction method for ice-melting and snow-melting asphalt concrete pavement, the difference from Embodiment 1 is:

[0144] (a) On the basis of determining the synthetic gradation of SMA-13 asphalt mixture without adding salt compound, the salt compound is used as a filler, and the gradation of the asphalt mixture is adjusted by screening the salt compound, according to the target mix The optimal asphalt ratio determined by the ratio is 6.1%; on the basis of the optimal asphalt ratio of 6.1% in the asphalt mixture, salt is used to replace part of the mineral powder, and the mix ratio is designed again, using 5.8%, 6.0%, 6.1%, 6.4% The Marshall specimen with a diameter of 101.6mm and a height of 63.5±1.3mm is compacted 55 times on both sides, and the number of specimens in each group is 6. , bitumen saturation, stability and flow value are tested and tested, and the optimum asphalt ratio of the asphalt mixture mixed with salt is determined to be 6.1%, and the corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com