Three-dimensional imaging method for realizing dendritic crystals in lithium metal battery by using photoacoustic imaging

A lithium metal battery, photoacoustic imaging technology, applied in the direction of material analysis, measuring devices, instruments, etc. through optical means, can solve the problems of not reaching the micron level, demanding sample preparation requirements, low time resolution, etc., and achieve improved performance and safety, faster detection and imaging speed, and the effect of large penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

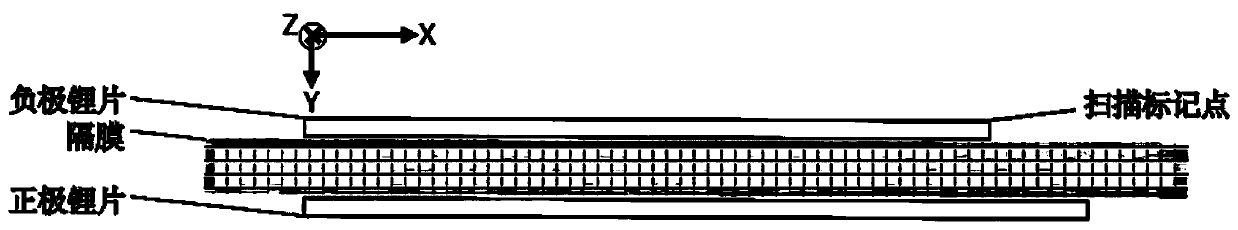

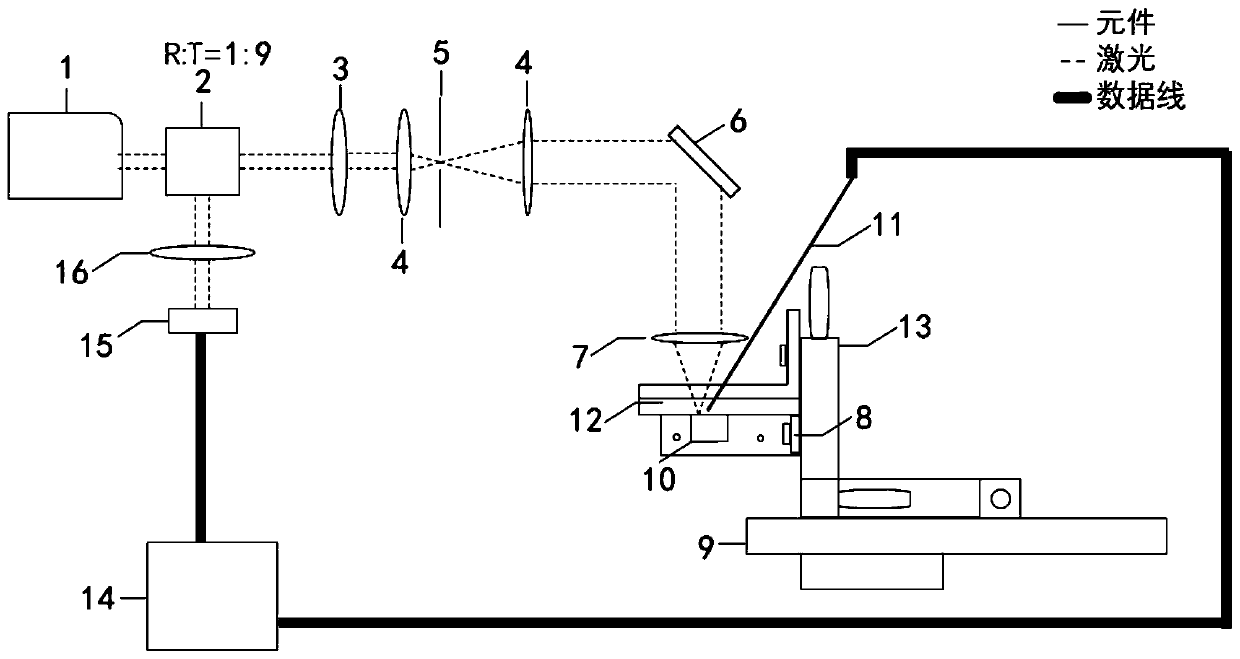

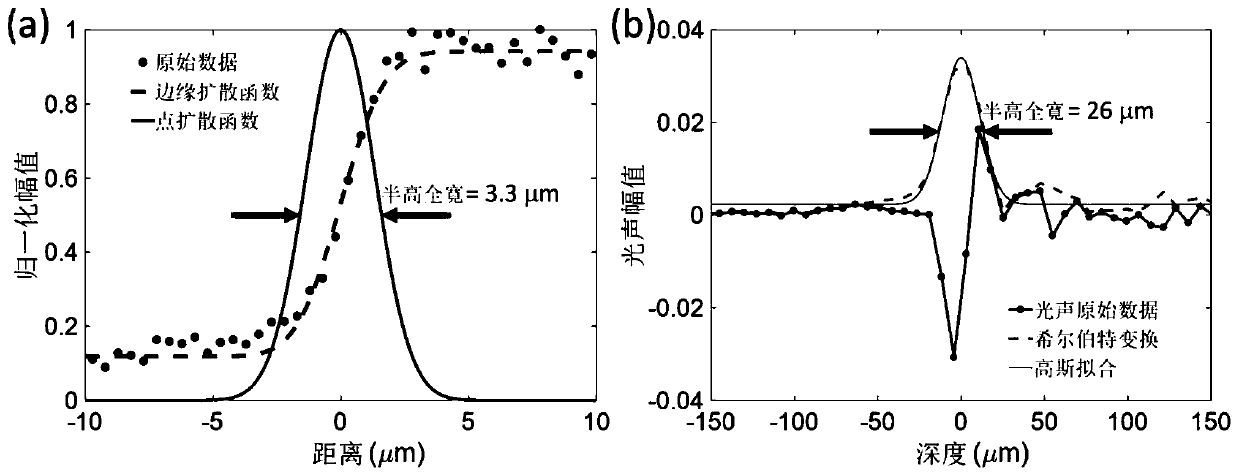

[0028] see Figure 1 to Figure 7 , a three-dimensional imaging method of dendrites in lithium metal batteries using photoacoustic imaging according to the present invention. The method mainly includes: (1) Three-dimensional imaging: different from pure optical imaging, photoacoustic imaging can obtain information in the depth direction and realize three-dimensional imaging. (2) Micron-level spatial resolution: This method uses a photoacoustic microscopic imaging system to scan the sample with a focused spot. The resolution is close to that of a traditional optical microscope, which is several microns, and has the potential to reach submicrons. Use a sharp blade to determine the resolution of a photoacoustic microscopy imaging system, such as im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com