Large-capacity wind field box transformer structure

A large-capacity, box-transformation technology, applied in power distribution substations, substation/switch layout details, switchgear and other directions, can solve the problems of large proportion of imported brands, inconvenient assembly and transportation, and high professional requirements, and achieve land acquisition and cost savings. The effect of civil construction area, maintenance of equipment acquisition cost, ease of transportation and hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

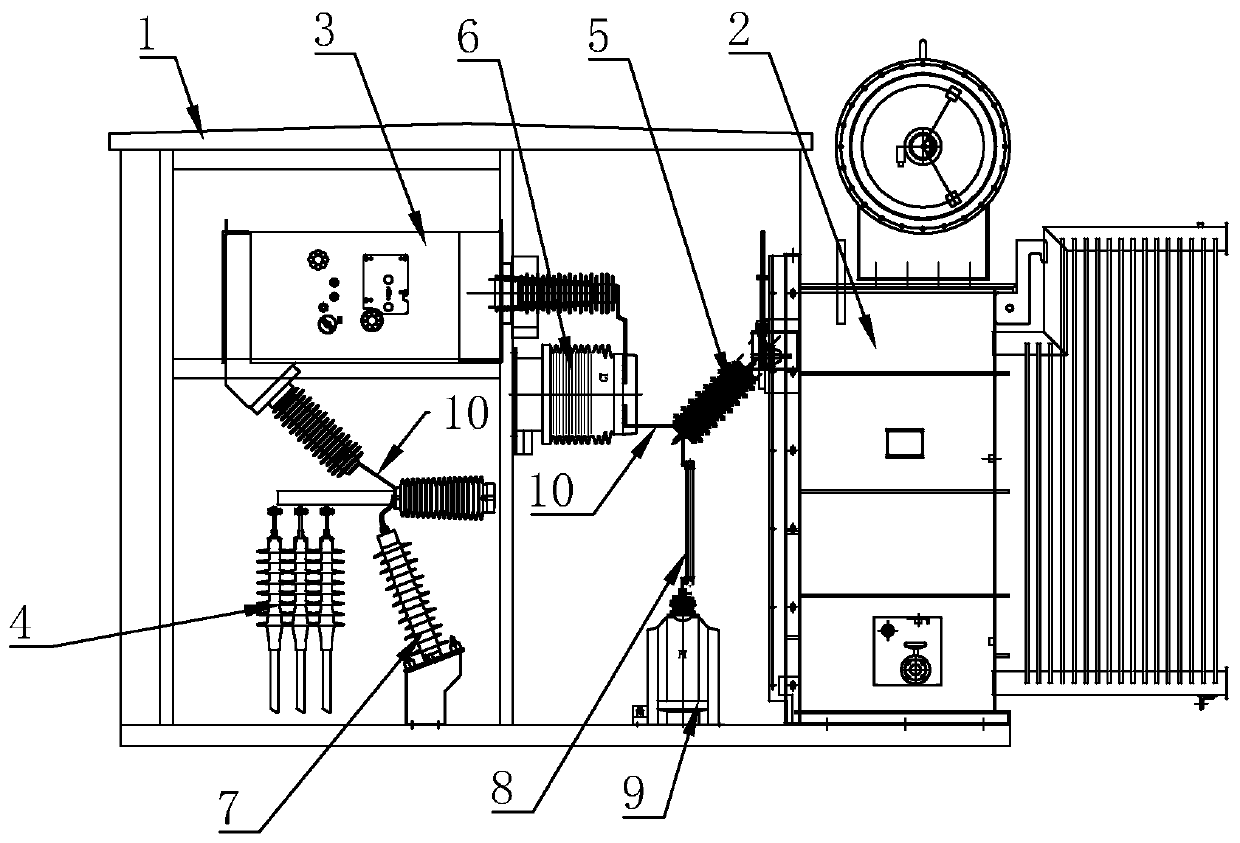

[0022] Such as figure 1 As shown, a large-capacity wind farm box substation structure includes: box substation housing 1, transformer 2, gas-filled switch assembly 3, high voltage cable 4, transformer outlet bushing 5, current transformer 6, lightning arrester 7, protective fuse 8. With voltage transformer 9;

[0023] The specific location and connection relationship of the above components are that the gas-filled switch assembly 3, the high-voltage cable 4, the transformer outlet bushing 5, the current transformer 6, the lightning arrester 7, the protective fuse 8, and the voltage transformer 9 are arranged in the box transformer housing 1; The transformer 2 is located on the outside of the box-substation housing 1, and is electrically connected to the current transformer 6 through the transformer outlet bushing 5, and the current transformer 6, the gas switch assembly 3, and the high-voltage cable 4 are electrically connected in turn;

[0024] In normal operation, the current is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com