TiO2@C/CdS composite material and preparation method thereof

A composite material, in-situ composite technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc. Low utilization rate and other problems, to achieve the effect of cost saving and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

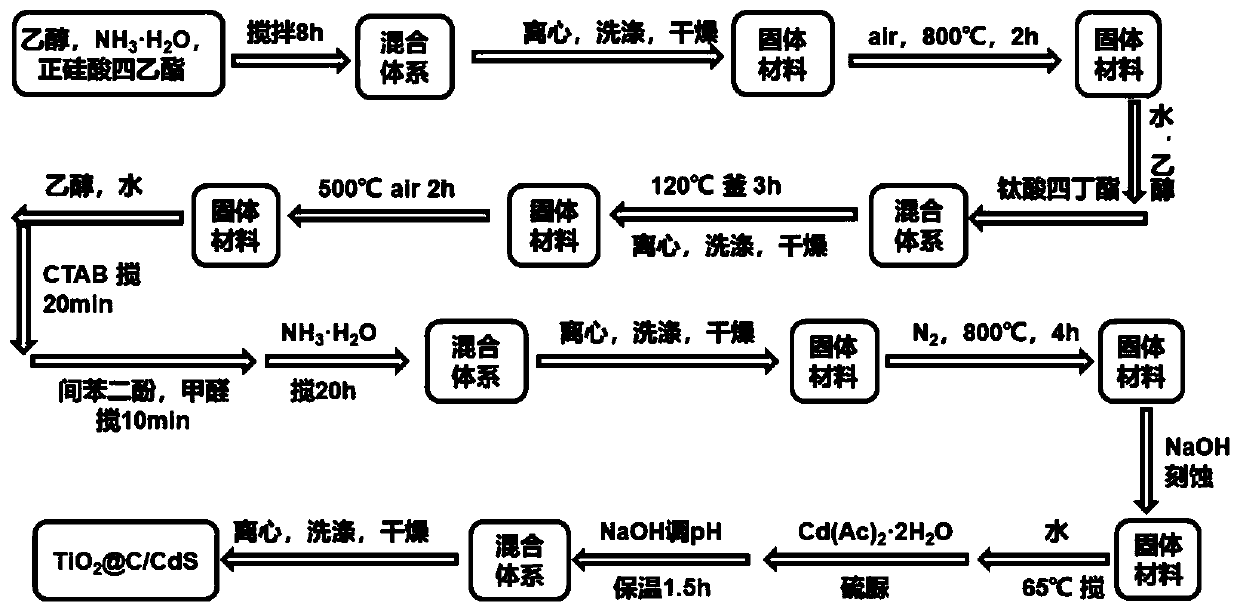

[0034] In the first step, ethanol, tetraethyl orthosilicate and NH 3 ·H 2 O was mixed at a volume ratio of 10:1:4, and magnetically stirred at room temperature for more than 8 hours;

[0035] In the second step, after the precipitate obtained in the first step is centrifugally washed and dried, the temperature is raised to 800°C at a rate of 5°C / min and then calcined for 2 hours to obtain SiO 2 nanospheres;

[0036]In the third step, 100 mg of the sample obtained in the second step was ultrasonically dispersed in deionized water and ethanol solution (volume ratio 1:37), and 0.6 mL of tetrabutyl titanate was added to it, stirred magnetically, transferred to a kettle, and kept at 120°C for 3 hours;

[0037] The fourth step is to take the kettle, cool it down naturally, wash and dry the product by centrifugation, then raise the temperature to 500°C at a rate of 5°C / min and then calcinate for 2 hours to obtain SiO 2 @TiO 2 core-shell structure;

[0038] In the fifth step, 200...

Embodiment 2

[0044] In the first step, ethanol, tetraethyl orthosilicate and NH 3 ·H 2 O was mixed at a volume ratio of 10:1:4, and magnetically stirred at room temperature for more than 8 hours;

[0045] In the second step, after the precipitate obtained in the first step is centrifugally washed and dried, the temperature is raised to 800°C at a rate of 5°C / min and then calcined for 2 hours to obtain SiO 2 nanospheres;

[0046] In the third step, 100 mg of the sample obtained in the second step was ultrasonically dispersed in deionized water and ethanol solution (volume ratio 1:37), and 0.6 mL of tetrabutyl titanate was added to it, stirred magnetically, transferred to a kettle, and kept at 120°C for 3 hours;

[0047] The fourth step is to take the kettle, cool it down naturally, wash and dry the product by centrifugation, then raise the temperature to 500°C at a rate of 5°C / min and then calcinate for 2 hours to obtain SiO 2 @TiO 2 core-shell structure;

[0048] In the fifth step, 20...

Embodiment 3

[0054] In the first step, ethanol, tetraethyl orthosilicate and NH 3 ·H 2 O was mixed at a volume ratio of 10:1:4, and magnetically stirred at room temperature for more than 8 hours;

[0055] In the second step, after the precipitate obtained in the first step is centrifugally washed and dried, the temperature is raised to 800°C at a rate of 5°C / min and then calcined for 2 hours to obtain SiO 2 nanospheres;

[0056] In the third step, 100 mg of the sample obtained in the second step was ultrasonically dispersed in deionized water and ethanol solution (volume ratio 1:37), and 0.6 mL of tetrabutyl titanate was added to it, stirred magnetically, transferred to a kettle, and kept at 120°C for 3 hours;

[0057] The fourth step is to take the kettle, cool it down naturally, wash and dry the product by centrifugation, then raise the temperature to 500°C at a rate of 5°C / min and then calcinate for 2 hours to obtain SiO 2 @TiO 2 core-shell structure;

[0058] In the fifth step, 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com