A rolling preparation method of aluminum alloy strip with poor performance in width direction

An aluminum alloy strip, direction difference technology, applied in metal rolling, metal rolling, rolling force/roll gap control, etc., can solve the problems of limiting the application of differential plate, automation and control system requirements, and achieve savings Manufacturing cost, lightweight continuous preparation, and the effect of reducing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

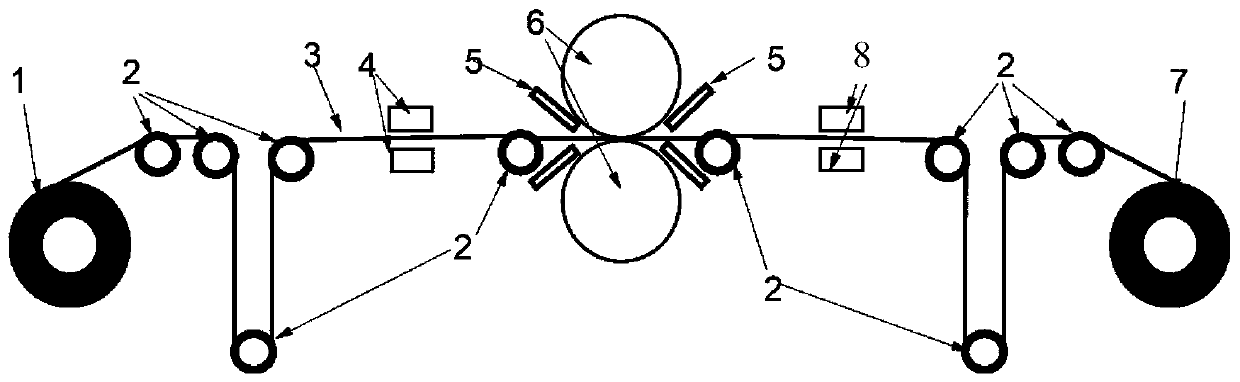

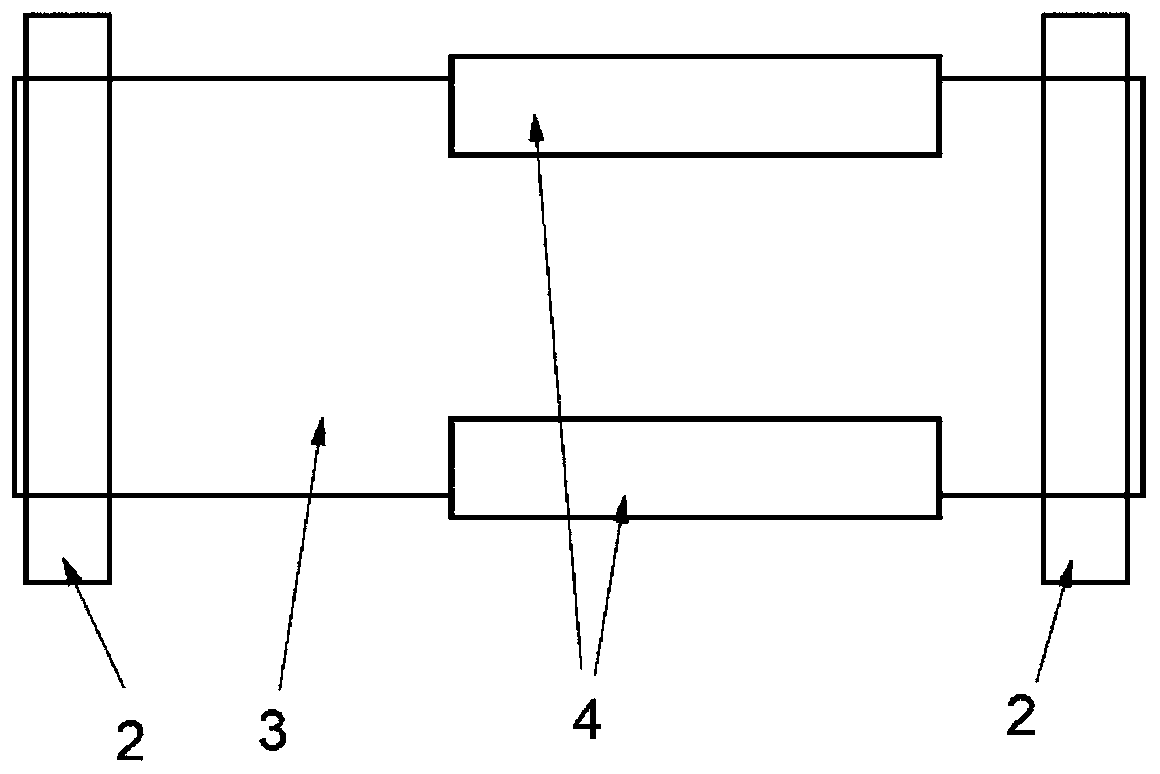

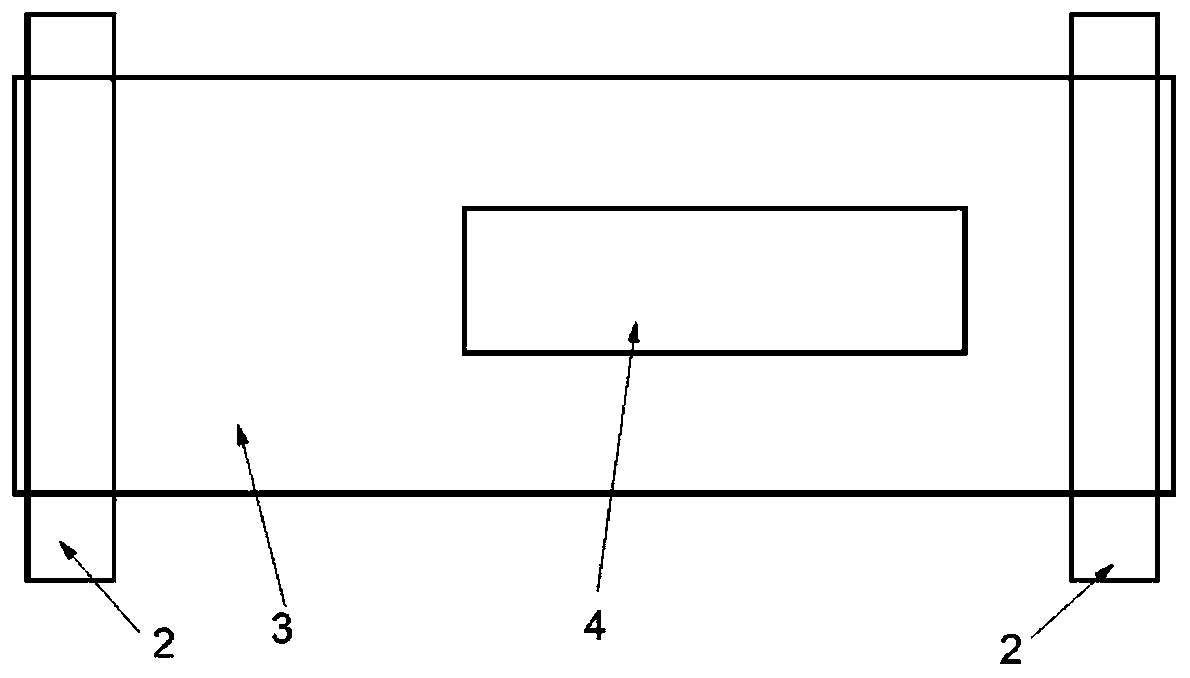

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0020] The invention discloses a rolling preparation method of an aluminum alloy strip with poor performance in the width direction. , so as to obtain strips with different mechanical properties. Therefore, in the rolling process, the cooling temperature before rolling is different for the strip products in different width regions, which can realize the difference in the mechanical properties of the rolled pieces in the width direction, and continuously prepare aluminum alloy strips with poor properties in the width direction. These strips can replace tailor-welded blanks welded with the same thickness but with different mechanical properties. figure 1 A specific and better implementation form of the present invention is shown, specifically including:

[0021] Step 1: The annealed hot-rolled aluminum alloy coil 3 is used as the raw material, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com