Method for manufacturing fire-retardant particleboard through continuous flat pressing

A technology of particleboard and shavings, applied in the direction of flat products, manufacturing tools, pretreatment of molding materials, etc., can solve problems such as no research results on particleboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

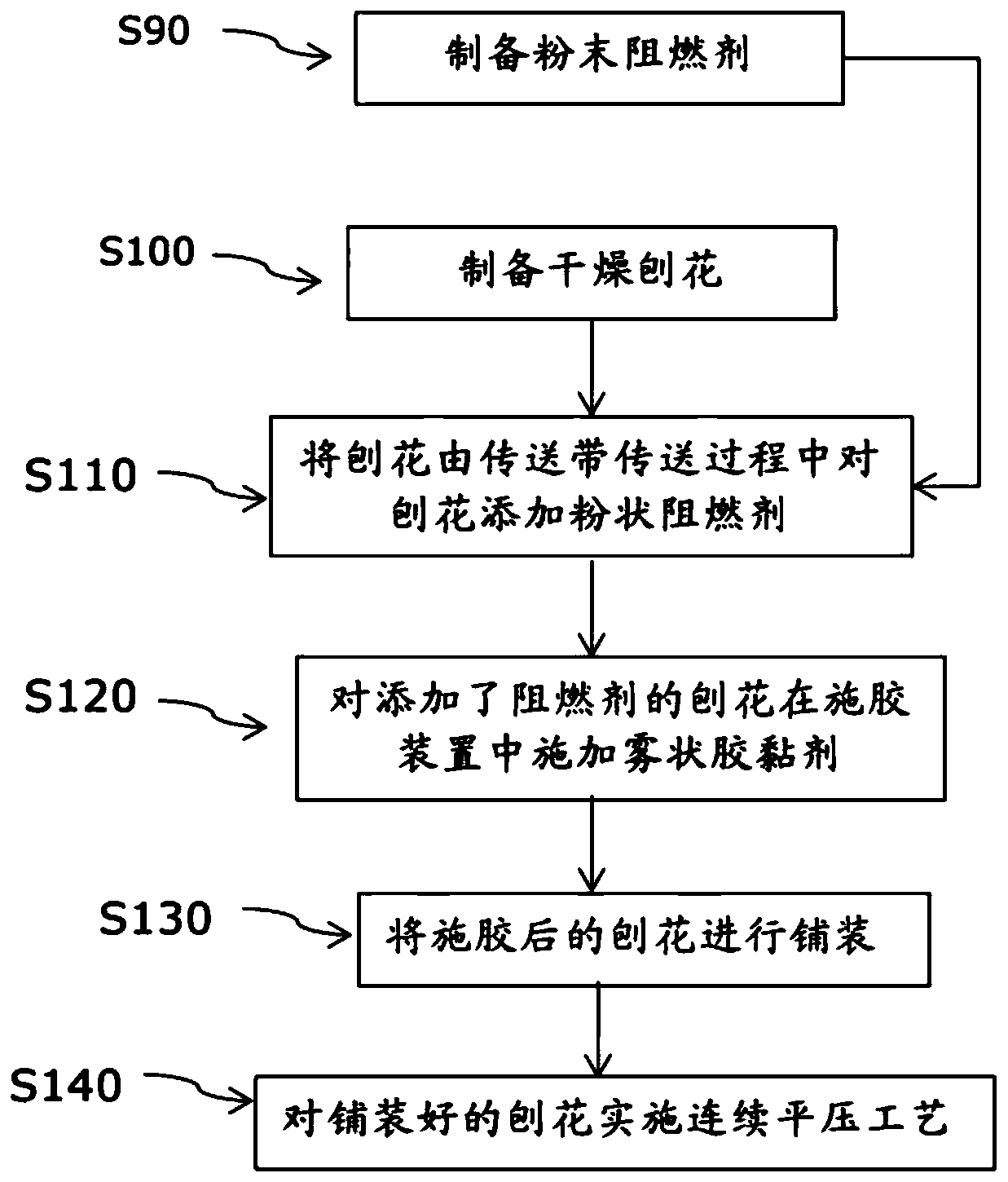

[0022] The manufacturing method of the present invention includes the following steps.

[0023] First, in step S100, dry shavings are prepared. Shaving the poplar fruit miscellaneous wood, according to the different positions of the particleboard, it can be planed into different sizes of shavings. Can be shavings of the same size. In addition, depending on the situation, the flaking process can also be omitted, and the market purchase method is adopted. Then the shavings that have been flaked are dried in the dryer 10, and the moisture content of the shavings is controlled by controlling the transmission time of the shavings in the rotary drum dryer and the temperature of the rotary drum dryer through the moisture content control mechanism 10a. Since shaving drying is a relatively mature technology in this field, details are omitted here.

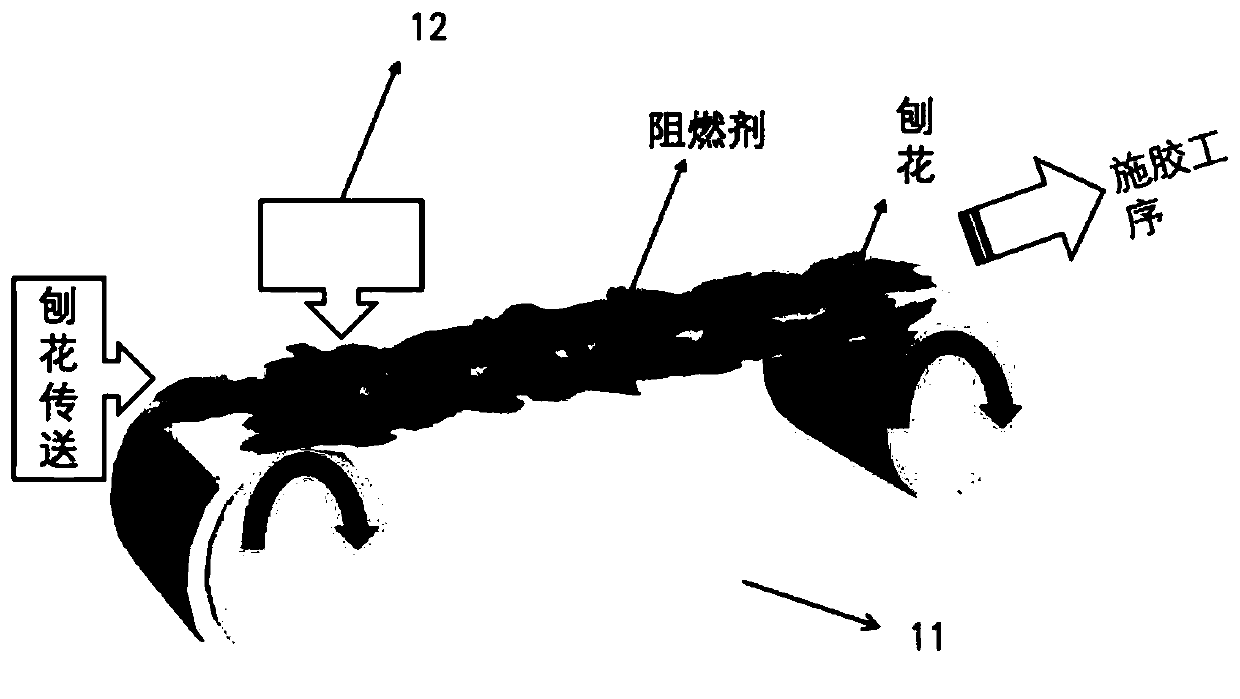

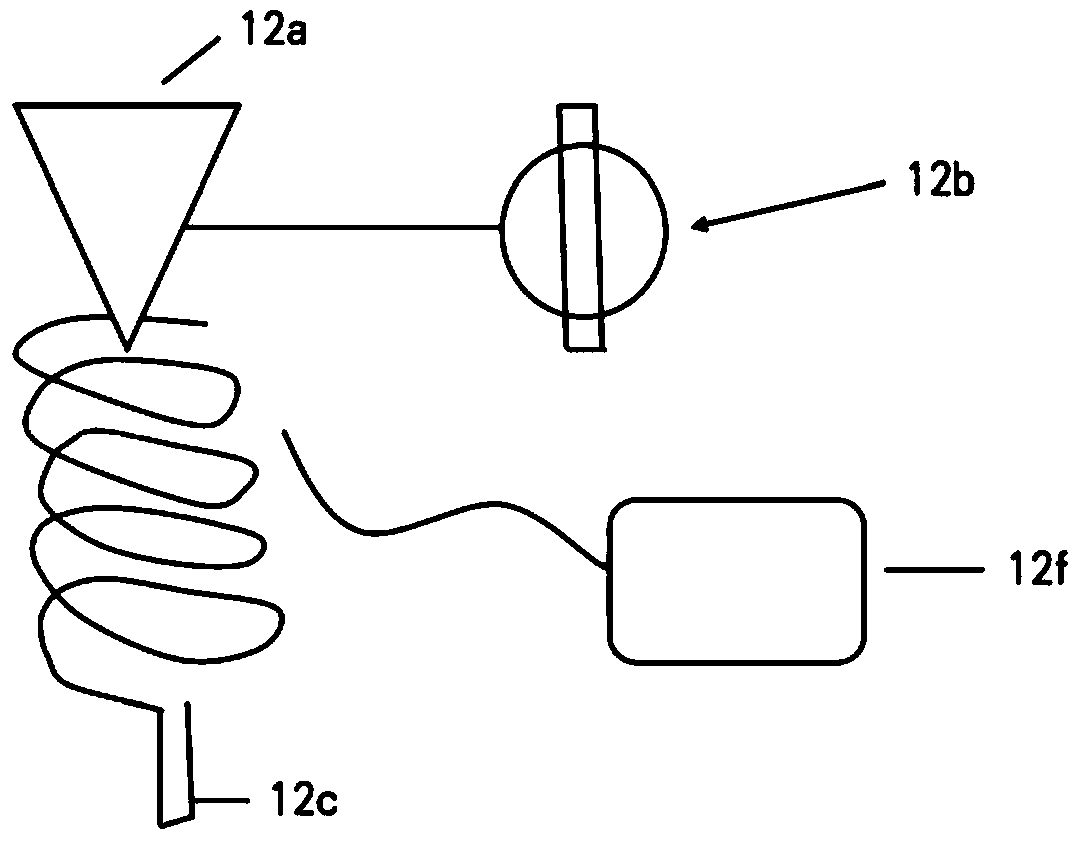

[0024] Next, in step S110 , a powdered flame retardant is added to the dried shavings during the process of transferring the dried shav...

no. 2 approach

[0032] The present invention provides a set of flame retardants suitable for continuous flat pressing to manufacture multi-layer flame-retardant particleboards for watch cores. Below, according to this specific implementation, and for the places different from the first embodiment, the above-mentioned manufacturing method is specifically described as follows:

[0033] Above-mentioned method also further comprises the operation S90 of preparing powdery flame retardant (referring to figure 1 ), respectively prepare the composite mixture of aluminum hydroxide / DOPO / thiourea with a composite ratio of 60:35:5-8 as the surface layer flame retardant and the composite ratio of 90:9:1-4 magnesium hydroxide / The compound mixture of antimony trioxide / hexaaminophenoxycyclotriphosphazene is used as the core flame retardant. As developed by the inventors, by adding such a flame retardant in layers, it can adapt to the higher press temperature of continuous flat pressing production without af...

experiment example 1

[0041] 60Kg of aluminum hydroxide, 35kg of DOPO flame retardant, and 5kg of thiourea flame retardant are used as the surface flame retardant, 90Kg of magnesium hydroxide, 9Kg of antimony trioxide, and 1Kg of hexaaminophenoxycyclotriphosphazene are fully blended and compounded As a core flame retardant.

[0042] Dry 770kg of surface shavings with a smaller size in a drum desiccant to a moisture content of 5%, and place them on a conveyor belt for transmission. Put the surface flame retardant in the dosage screw hopper of the flame retardant metering screw and add it to the conveying skin The shavings are controlled so that the addition ratio of flame retardant is 13%, and then sent to the glue mixer for sizing, and the sizing amount is controlled to be 10%

[0043] Dry 3300kg of the larger core layer of shavings in a drum desiccant to a moisture content of 3%, and place it on a conveyor belt for transmission. Put the core layer flame retardant in the dose screw hopper of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com