Unsaturated polyester resin for vacuum infusion process and resin composition thereof

A polyester resin, vacuum introduction technology, applied in the field of unsaturated polyester resin, can solve problems such as lack of matrix resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

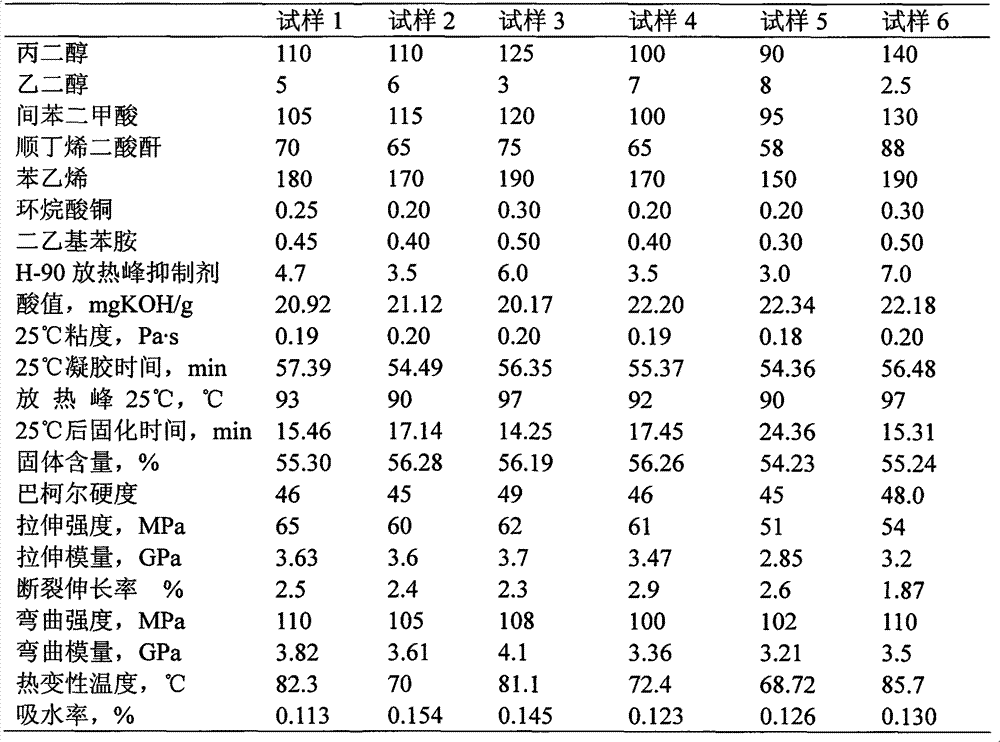

Examples

Embodiment 1

[0101] The preparation of embodiment 1 unsaturated polyester resin

[0102] Propylene glycol, ethylene glycol, isophthalic acid and maleic anhydride are used as polymerized monomers, styrene is used as a crosslinking agent, H-90 exothermic peak inhibitor, diethylaniline and copper naphthenate are used as auxiliary agents. The method for preparing unsaturated polyester resin is as follows:

[0103]Put monomers such as propylene glycol, ethylene glycol and isophthalic acid, and an appropriate amount of monobutyltin oxide catalyst into the reactor, and carry out polycondensation reaction at 200-210°C under the protection of nitrogen. When the solid acid value is below 20mgKOH / g, lower the temperature to below 155°C, add maleic anhydride into the reactor, and continue to heat up to 200-210°C for reaction; when the solid acid value is 49-53mgKOH / g, vacuumize To vacuum degree -80kPa. When the cone-plate viscosity (No. 3 rotor, 150°C) is 600-690mPa·s, release the vacuum and cool it...

Embodiment 2

[0104] The preparation of embodiment 2 unsaturated polyester resin and composition thereof

[0105] Propylene glycol, ethylene glycol, isophthalic acid and maleic anhydride are used as polymerized monomers, styrene is used as a crosslinking agent, H-90 exothermic peak inhibitor, diethylaniline and copper naphthenate are used as auxiliary agents. The method for preparing unsaturated polyester resin is as follows:

[0106] Put monomers such as propylene glycol, ethylene glycol and isophthalic acid, and an appropriate amount of catalyst into the 350L reactor in sequence. Under the protection of nitrogen, start to heat up while stirring, keep warm for 1 hour when the temperature rises to 155-160°C, and control the temperature of the distillation head at 100-102°C. Stop feeding nitrogen into the reaction kettle, and increase the pressure in the reaction kettle, control the pressure of the reaction kettle to 1-2 bar, and raise the temperature to 205-210° C. to continue the reaction...

Embodiment 3

[0108] The preparation of embodiment 3 unsaturated polyester resin and composition thereof

[0109] Propylene glycol, ethylene glycol, isophthalic acid and maleic anhydride are used as polymerized monomers, styrene is used as a crosslinking agent, H-90 exothermic peak inhibitor, diethylaniline and copper naphthenate are used as auxiliary agents. The method for preparing unsaturated polyester resin is as follows:

[0110] ①Put propylene glycol, ethylene glycol, isophthalic acid and monobutyltin oxide into a 350L reactor in sequence.

[0111] ②Pass nitrogen gas (flow rate: 0.5m3 / h) for 10 minutes, make the inside of the reactor in a state of nitrogen blanketing, start stirring and start to heat up, keep warm for 1 hour when the temperature rises to 155-160°C, and immediately condense vertically when the water comes out of the distillation head Cooling water is passed through the device, and the temperature of the distillation head is controlled to be 100-102°C.

[0112] ③ Stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com