High-strength heat-resisting mica tape production technology

A production process and technology of mica tape, applied in the direction of layered products, lamination, lamination devices, etc., can solve the problems of poor moisture resistance, reduced flame retardancy, easy heat generation, etc., and achieve high temperature resistance and moisture resistance. The effect of moisture-proof performance and strong combustion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

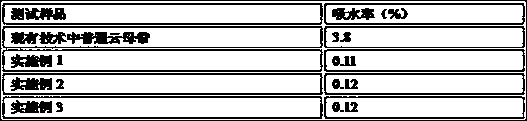

Examples

Embodiment 1

[0028] A high-strength heat-resistant mica tape production process, it comprises the following steps:

[0029] 1) Mica paper reinforcement, deploying liquid reinforcement materials, spraying on the upper and lower sides of mica paper, after spraying, place in an oven for drying, cooling, and winding to obtain reinforced mica paper;

[0030] 2) Glue on the car, and apply adhesive on the upper and lower sides of the reinforced mica paper;

[0031] 3) Adhesive layering, laminating glass fiber cloth on the upper and lower sides of the mica paper to obtain a semi-finished mica tape;

[0032] 4) Drying, put the semi-finished mica tape into the oven for drying;

[0033] 5) Rolling after cooling, the rolled mica tape blank is cut into strips by a slitting machine and rolled to obtain a high-strength heat-resistant mica tape.

[0034] Preferably, the preparation of the liquid supplement material in step 1) includes the following steps:

[0035] ① Prepare the following raw materials ...

Embodiment 2

[0045] A high-strength heat-resistant mica tape production process, it comprises the following steps:

[0046] 6) Mica paper reinforcement, deploying liquid reinforcement materials, spraying on the upper and lower sides of the mica paper, after spraying, place it in an oven for drying, cooling, and winding to obtain reinforced mica paper;

[0047] 7) Glue on the car, and apply adhesive on the upper and lower sides of the reinforced mica paper;

[0048] 8) Adhesive layering, laminating glass fiber cloth on the upper and lower sides of the mica paper to obtain a semi-finished mica tape;

[0049] 9) Drying, put the semi-finished mica tape into the oven for drying;

[0050] 10) Rolling after cooling, the rolled mica tape blank is cut into strips by a slitter and rolled to obtain a high-strength heat-resistant mica tape.

[0051] Preferably, the preparation of the liquid supplement material in step 1) includes the following steps:

[0052] ① Prepare the following raw materials i...

Embodiment 3

[0062] A high-strength heat-resistant mica tape production process, it comprises the following steps:

[0063] 11) Mica paper reinforcement, deploying liquid reinforcement materials, spraying on the upper and lower sides of mica paper, after spraying, place in an oven for drying, cooling, and winding to obtain reinforced mica paper;

[0064] 12) Glue on the car, and apply adhesive on the upper and lower sides of the reinforced mica paper;

[0065] 13) Adhesive layering, laminating glass fiber cloth on the upper and lower sides of the mica paper to obtain a semi-finished mica tape;

[0066] 14) Drying, put the semi-finished mica tape into the oven for drying;

[0067]15) Rolling after cooling, the rolled mica tape blank is cut into strips by a slitter and rolled to obtain a high-strength heat-resistant mica tape.

[0068] Preferably, the preparation of the liquid supplement material in step 1) includes the following steps:

[0069] ① Prepare the following raw materials in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com