System and method for detection and treatment of plate width accidents in float glass forming process

A molding process, float glass technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurate and untimely human subjective judgment, lack of intelligence, etc., to reduce the risk of secondary accidents, improve the level of technology, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

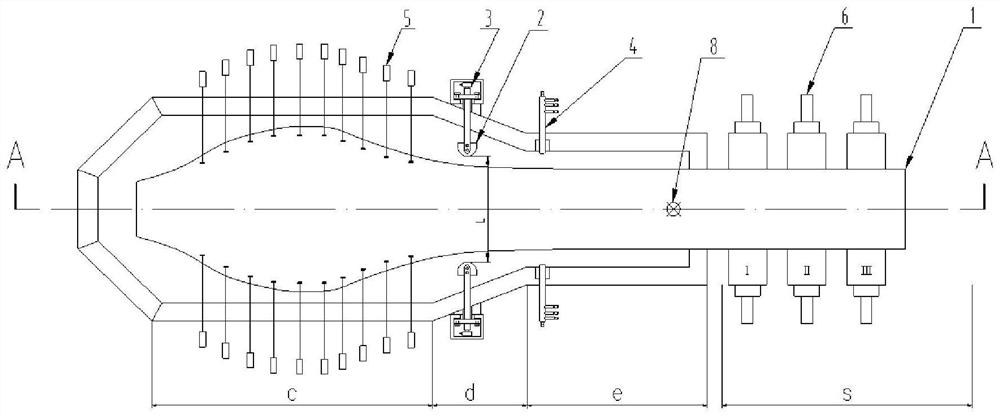

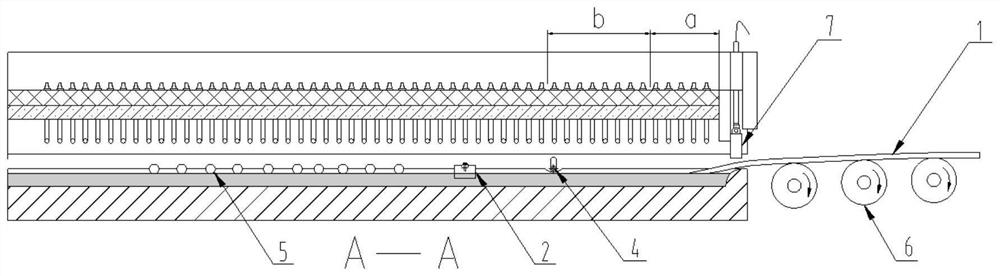

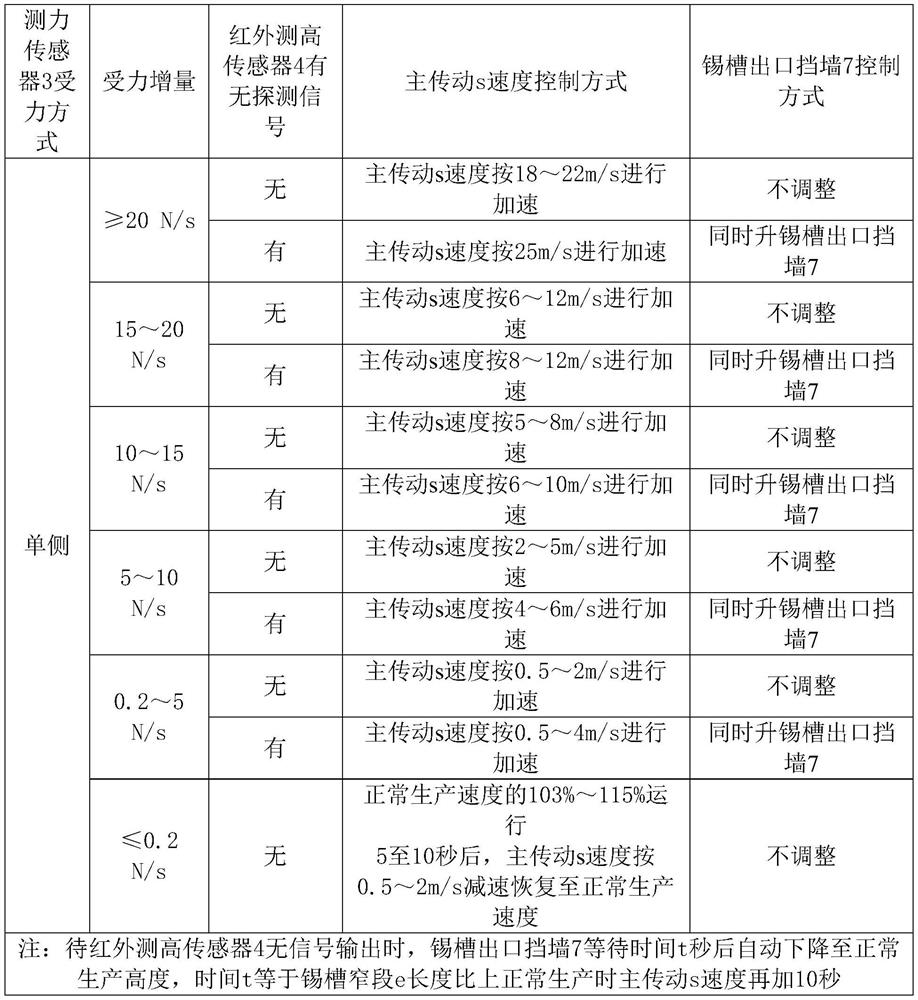

[0073] Embodiment 1: The load cell 3 is installed on the crimping device 2, the crimping device 2 is installed at the position of the shrinkage section, the crimping devices 2 are installed in pairs, and the clear width of the contact parts between the two crimping devices 2 and the glass ribbon 1 is 4100mm, the inner width of the narrow section e of the tin bath is 4300mm, and the normal production width of the glass ribbon 1 is 3600mm. The infrared height measuring sensor 4 is installed at the entrance position of the narrow section e of the tin bath downstream of the crimping device 2, the pulling direction is 1600mm from the crimping device, the probe level is 25mm from the tin liquid level, and the glass production thickness specification is 5.00mm or less. Connect the electrical signal of force sensor 3 and infrared height measuring sensor 4 to the DCS system with wires, connect the main drive s control line, the tin bath exit retaining wall 7 control line, the tin bath e...

Embodiment 2

[0074]Embodiment 2: Install the load cell 3 on the crimping device 2, the crimping device 2 is installed at the position of the shrinkage section, the crimping devices 2 are installed in pairs, and the clear width of the contact parts between the two crimping devices 2 and the glass ribbon 1 is 4900mm, the inner width of the narrow section e of the tin bath is 5200mm, the length of the narrow section e of the tin bath is 12000mm, and the normal production width of the glass ribbon 1 is 4600mm. The infrared height measuring sensor 4 is installed at the entrance position of the narrow section e of the tin bath downstream of the crimping device 2, the pulling direction is 2000mm from the crimping device, the probe level is 20mm from the tin liquid level, and the glass production thickness specification is 5.00mm or less. Connect the electrical signal of the infrared temperature sensor 8 at the outlet of the tin bath, the electrical signal of the force sensor 3 and the electrical s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com